Film heated floor: installation under linoleum

Preparing the most important tools, as well as materials for installing film heated floors, is key. If this is not done, you can expect any problems.

The content of the article

Preparation of materials and tools for installation of film flooring

In order for the installation of the film floor to proceed as quickly as possible and without errors, it is worth preparing the thermal film and all additional elements.

Don’t forget about the thermostat, as well as any other heat-reflecting material. You will also need plastic film, tape, a knife and scissors, a stapler and a screwdriver. You can add pliers to this list.

Instructions for installing film heated floors under linoleum

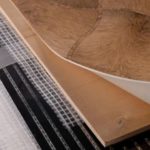

First, prepare the base and level the plane. To do this, we can recommend screeding with a special solution. Waterproofing is laid on it, and then sheets of plywood are laid. Laying plywood on the floor is done in a checkerboard pattern.

Then you need to take measurements and draw up a plan on which the places with thermal film will be indicated. When everything is ready, you need to choose a place on the wall where the thermostat will be installed. This place should be accessible, and the distance to the source should be minimal. On sale you can find rolls completely ready for installation.In order to simplify the task, you need to secure the thermal insulator with double-sided tape. Alternatively, you can try staples and a stapler. These tools will help you do without more expensive devices that not everyone has. It is important to note that all joints that are located between the strips must be sealed with tape. The entire surface must be perfectly sealed.

Now all that remains is to put the thermal film on. Remember the markings and that the bottom side of the thermal film should be facing the heat-reflecting film. By the way, if we are talking about low furniture, then there is no heating under it at all. This can cause irreparable damage to the furniture, causing it to quickly become unusable.

The underfloor heating infrared film is laid under linoleum in such a way that the time comes for insulation and connection. First, you need to remember the requirements of the PUE, as well as all the recommendations of the material manufacturer. You can learn about them from the instructions. It is also necessary to use all connectors, as well as special insulating materials that come with the kit. Only if they are present can you be sure that the structure will last a long time and there will be no problems with it.

How to lay a heated film floor under linoleum? So, all cut points of a wide copper busbar are insulated using bitumen insulation. Where the wires connect to the bus are located, contact clamps are installed. They are squeezed as tightly as possible with pliers.

Each strip of special thermal film must be secured with tape. If this is not done, then you can expect any unpleasant consequences.If everything is fine, you can connect the wires for power supply. In order to increase the service life of the entire structure, it is recommended to tin all exposed ends. This is an extremely dangerous job, because an inexperienced worker can get an electric shock. However, without this, the contact at the connection points may be too weak.

Now they install the notorious thermostat on the wall, and also connect the system to the mains. This completes the installation and you can finally breathe a sigh of relief.

Possible errors and their elimination

When installing a heated film floor, installation of which under linoleum can cause difficulties, errors may occur.

When installing a heated film floor, installation of which under linoleum can cause difficulties, errors may occur.

- Errors inevitably occur during work. This is a completely normal and natural process. In order to avoid them, you need to understand in advance what the amount of work is. The most common mistake is a simple lack of time. In order to prevent such developments, it is better to leave plenty of time for editing.

- Also, some manage to melt linoleum. This is possible when connecting the installation wires.

- Don’t forget to fix the strips of thermal film. To do this you need to use tape.

After all the work is completed, they conduct testing and see how the design as a whole works. If any problems arise with it, it is best to entrust the installation to professionals.