Calender linoleum base - what is it?

It cannot be argued that the result directly depends on the preparation and the quality of the process itself. Therefore, to make long-lasting linoleum you will need to know all the features and carefully prepare for the activity. Accordingly, in this article we will try to consider in detail all the aspects that you need to know in advance, as well as special cases that you may encounter on the way to the end.

The content of the article

What is a calendered linoleum base?

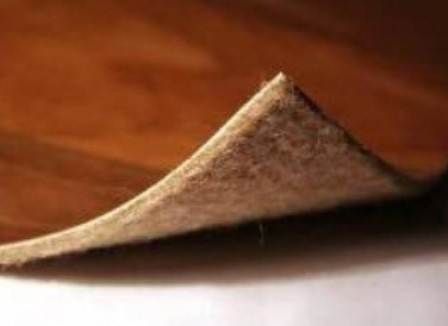

In order not to delve too deeply into the topic, you just need to know that the output directly appears as a product of a certain thickness, which is a film of a continuous format - this is a calender base. It is important to understand that the production of such material is quite labor-intensive, since it is considered a construction item.

Briefly, we can mention the pouring of a special mass, which is further processed between two rollers, and the output is exactly the invention that was mentioned above in the article. In the modern world, a huge number of manufacturers use exactly the described technology.

Production technology

As mentioned earlier, the entire manufacturing process is a step-by-step process. Therefore, let's move straight to the actions themselves:

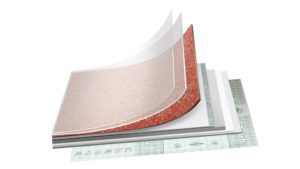

The first step is the procurement of raw materials. To begin with, each component is taken separately and certain manipulations are performed with it. First, dry and sift. After which comes the mixing stage. The components are taken in the required proportions. Next, two stages are applied. The first of which is the use of a paddle mixer. The mixture of all elements occurs directly in it. As for the second stage, it is the use of a rotary product. The difference from the first mechanism is that in the rotor the temperature reaches a certain degree, and this can be a range from 120 to 160.

The first step is the procurement of raw materials. To begin with, each component is taken separately and certain manipulations are performed with it. First, dry and sift. After which comes the mixing stage. The components are taken in the required proportions. Next, two stages are applied. The first of which is the use of a paddle mixer. The mixture of all elements occurs directly in it. As for the second stage, it is the use of a rotary product. The difference from the first mechanism is that in the rotor the temperature reaches a certain degree, and this can be a range from 120 to 160.- In order for the mixture to enter the calender, it must first pass through the conveyor. Most often, the model of the invention is of a closed type so that possible harmful substances are not released into the environment. In addition, with the help of this variety, the degree does not decrease, and the product does not lose such a property as plasticity.

- After the substance has been processed in two or three stages, it goes into the calender. It is there that the necessary parameters, both thickness and length, are formed.

Advantages and disadvantages

Of course, to make an appropriate choice, it is best to weigh the pros and cons. Actually, let's start analyzing the issue with the advantages.

- The first thing to note is the endurance of mechanical impact.

- Next - maximum ease of care for the material.

- There is a guarantee that the substance is environmentally safe. So when interacting with this type of linoleum, you don’t have to worry about possible harm to your health.

- Resistance to chemical compounds.

Speaking about the disadvantages of this technology, it is worth noting the following points:

- Not so durable service life.

- A bad choice for use in the home, since the colors of such material are not for everyone.