What does linoleum class mean?

Quite often, when choosing a floor covering, consumers have difficulty making a choice. Recently, linoleums have become very popular. Modern manufacturers offer a very diverse range of this type of flooring and it is difficult to figure out which one is best to choose for certain purposes. Linoleums are classified according to different criteria, these are classes, let's look at the main ones to make it easier for you to choose the appropriate option.

Quite often, when choosing a floor covering, consumers have difficulty making a choice. Recently, linoleums have become very popular. Modern manufacturers offer a very diverse range of this type of flooring and it is difficult to figure out which one is best to choose for certain purposes. Linoleums are classified according to different criteria, these are classes, let's look at the main ones to make it easier for you to choose the appropriate option.

The content of the article

What is linoleum class

First of all, it is worth understanding which indicators are the most significant when choosing linoleum. Labeling is, in fact, all the most important information. Or rather, all the necessary information about each type of linoleum is encrypted in the marking code.

REFERENCE. It is almost impossible to determine the wear resistance characteristics and quality of the material by eye. You, of course, can determine such characteristics as the thickness of the canvas, the brightness of the applied pattern and others, but this will not help in any way determine which top layer was applied.

Based on this, we can conclude that even outwardly nondescript and relatively thin linoleum can be significantly more reliable than thick, bright and beautiful material.

IMPORTANT. Having understood the markings, you will be able to accurately choose the floor covering that suits you in the future.

Wear resistance classification

Such a criterion as wear resistance is one of the most important when choosing a floor covering. Wear resistance - This the ability of the flooring surface to withstand regular mechanical loads.

NOTE. Do not confuse concepts such as abrasion and wear resistance, they are different.

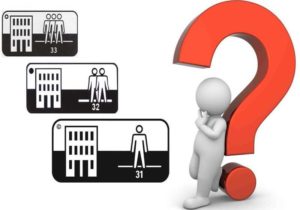

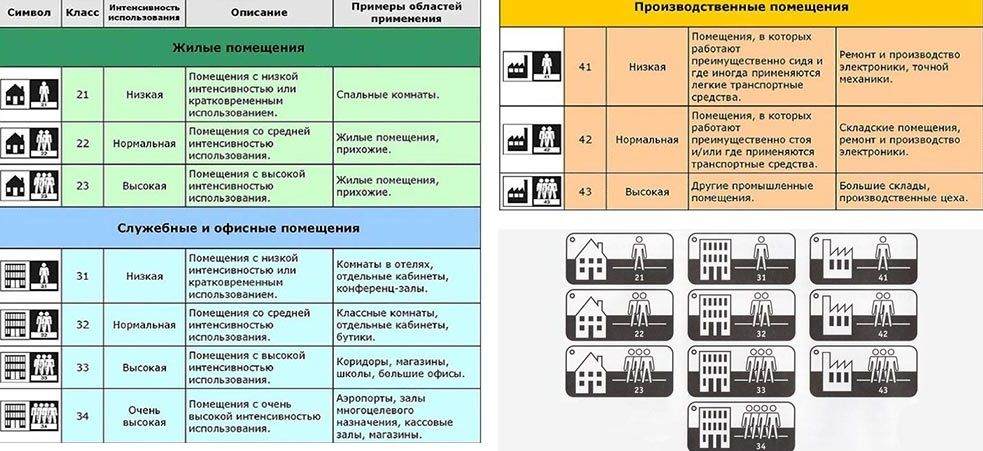

Each material model is assigned a two-digit number, where the first digit indicates the type of room, and the second indicates the wear resistance of the top layer of coating. Before assigning certain parameters to a material, the manufacturer carries out all the necessary tests. It is worth highlighting the following load levels, which are divided into categories:

- Low load level.

- Average load level.

- High and intense load.

- Increased load.

Room type

If the floor covering label shows the number 2, this means that you are considering household linoleum. On the packaging, the production usually indicates a house. Among the advantages it is worth highlighting:

- Lowest cost.

- The material is pleasant to the touch and comfortable to walk on barefoot.

- Excellent thermal insulation performance.

- Variety of choice.

- Environmentally friendly material.

In these models, the thickness of the protective layer is approximately 0.1-0.35 mm, while the total thickness is in the range of 1.5-5 mm. The service life is approximately 5 years, depending on the conditions of use.

21st grade. This is a soft material that experts recommend laying in places where there is low load. These could be bedrooms, dressing rooms or storage rooms.

21st grade. This is a soft material that experts recommend laying in places where there is low load. These could be bedrooms, dressing rooms or storage rooms. - 22nd grade. An average load is acceptable here. An excellent solution for arranging floors in children's rooms, living rooms and bedrooms.

- 23rd grade.This category is considered the most common and is in demand more often than others. Suitable for installation in places with increased dynamic load, for example, corridors, halls.

If the number 3 is indicated in the floor covering marking, this means that you are considering commercial linoleums; you might also have heard the name - office. The packaging usually indicates the production location is an office building. The service life reaches 15 years. Among the advantages it is worth highlighting:

- Wide variety of textures and colors.

- Increased wear resistance.

- Very dense structure.

The thickness of the protective layer is in the range of 0.3-0.6 mm. Suitable for use in areas with high traffic.

31st grade. This is an excellent choice for offices of bosses and accountants. Where there is not particularly high traffic of people. These could also be hotel rooms.

31st grade. This is an excellent choice for offices of bosses and accountants. Where there is not particularly high traffic of people. These could also be hotel rooms. - 32nd grade. Features improved characteristics. Suitable for kindergartens, shops and reception areas. This option is often chosen for the home, since for a very low cost you get a truly reliable floor covering.

- 33rd grade. Highly durable material. This is an excellent solution for office spaces with high traffic levels.

- 34th grade. This option is the most reliable and durable. It is chosen for installation in supermarkets, airports, and train stations.

If the floor covering is marked with the number 4, this means that you are dealing with industrial linoleum. The factory indicates production on the packaging. This type of coating is used exclusively in industry. Since the material is subject to increased criteria, the manufacturer offers a very limited color option.The service life of such coating is at least 10 years or more. The thickness of the protective layer is 0.6 mm. There is one significant flaw — high price.

41 class. It is used in production, where mostly sedentary work is required. These can be workshops, technical control departments and others.

41 class. It is used in production, where mostly sedentary work is required. These can be workshops, technical control departments and others. - 42 class. Suitable for use in almost any industrial premises. The exception is those in which special equipment moves.

- 43rd grade. This type of material is the most durable and high quality. Suitable for use in rooms with high traffic intensity of both people and equipment.

Extra options

In addition to the listed parameters, there are additional ones that you should also pay attention to when making your choice. On the reverse side of the canvas an additional classification must be indicated, namely:

- Smoke formation. Denoted by the letter “D”. The rule here is that the lower the number, the better. There may be three variants of numbers.

- Flammability. This indicator is indicated by the letter “G”; this criterion indicates what danger the product poses in the event of fire. There are 4 groups.

- Flammability and flame distribution. The first indicator is designated by the letter “B”; the higher the number, the lower the quality of the material. The second indicator is indicated by “RP”; here, too, the lower the number, the better.

These parameters directly determine the safety of those who will use linoleum. All tolerances are specified in the document - GOST 30402. May withconclude that in compliance The classes of linoleum determine its purpose, and therefore its application.

23 and 31 are the same protective layer, 32 and 41, 33 and 42, 34 and 43 are the same protective layer.