Laying underlay under laminate

Anyone can lay laminate flooring. This is not difficult to do with your own hands, however, you need to know the installation rules and do everything according to the existing schemes. This process consists of several steps, and none of them can be skipped. Otherwise, you risk ruining the final result. Today we will pay attention to laying the substrate under the laminate.

Anyone can lay laminate flooring. This is not difficult to do with your own hands, however, you need to know the installation rules and do everything according to the existing schemes. This process consists of several steps, and none of them can be skipped. Otherwise, you risk ruining the final result. Today we will pay attention to laying the substrate under the laminate.

The content of the article

Why do you need a backing for laminate flooring?

It’s worth saying right away that the substrate is a necessary element. It cannot be ignored, because it takes on important functions, without which the result will not last long. Its functions primarily include preventing:

coating deformation;

coating deformation;- broken locks;

- the appearance of condensation between the final and ground coating;

- proliferation of pathogenic microorganisms under the laminate, primarily fungus.

This layer will also help reduce the sound of footsteps.

But at the same time, you should not increase the value of this element. Some hobbyists prefer to replace the process of leveling the floor by laying underlayment. But this absolutely cannot be done. Also, do not forget that the material for this stage must be selected with high quality, but at the same time, match the quality of the boards themselves.

Important! Using an underlay is not a substitute for leveling the base.

Types of substrate

There are several types of substrate.They differ in composition, and, consequently, in quality, service life and price. Let's look at the most popular options, and also recommend the optimal type. Before considering options, remember that this layer must match the laminate in quality and price; this rule also works in the opposite direction.

Bitumen-cork

This option is based on special paper. It is impregnated with bitumen and then sprinkled with cork chips. That's why we have this name.

This option is based on special paper. It is impregnated with bitumen and then sprinkled with cork chips. That's why we have this name.

The main advantages of this option are durability and strength. It is able to withstand heavy loads and protect the boards from kinks even in difficult operating conditions. This type is intended primarily for expensive types of laminate.

Important! The wear resistance of the substrate and the laminate should be as similar as possible.

Considering all the positive qualities of this type, do not forget about its high price. This cannot be called a disadvantage, since you have to pay for quality. But if you have an expensive type of wood laminate, then it is better to overpay than to use a cheap underlay for an expensive finish.

Foamed polyethylene

The name speaks for itself. This is a lightweight sheet material that can be laid simply and quickly. The advantages include the following:

cheapness;

cheapness;- ease of installation;

- prevalence;

- moisture resistance;

- not susceptible to mold;

- not afraid of rodent attacks.

The presence of these positive qualities contributed to the wide spread of this material. However, it also has a significant disadvantage - subsidence. Over time, this material tends to lose its shape, resulting in sagging. For a laminate floor, this can lead to breakage of boards and locks, the formation of holes, and sagging of the finish.Thus, this material can be used for short-term use or with a gentle regime.

Foamed polystyrene

Polystyrene is the best option for those who want to find the best balance between price and quality. This is the average version of the two previous ones both in terms of pricing and quality. This material can already be used for medium and higher quality laminate. Since its price is higher than the previous one, for cheap types of wood it is better to purchase polyethylene foam.

Polystyrene is the best option for those who want to find the best balance between price and quality. This is the average version of the two previous ones both in terms of pricing and quality. This material can already be used for medium and higher quality laminate. Since its price is higher than the previous one, for cheap types of wood it is better to purchase polyethylene foam.

Polystyrene holds its shape well, does not sag, has a fairly long service life, and is of average price. The second most common option among masters.

It also has a minus - it is a fire hazard, that is, it is easily flammable. But if the fire reached the floor substrate, nothing could survive.

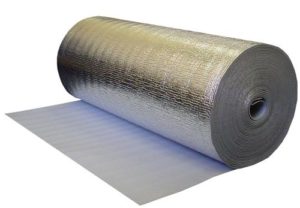

Polyurethane on foil

And one more candidate on the list of good materials. Of course, any material can sag over time, but the sagging of this material occurs very slowly. Thus, its service life is very long. It is also designed for more expensive types of wood.

And one more candidate on the list of good materials. Of course, any material can sag over time, but the sagging of this material occurs very slowly. Thus, its service life is very long. It is also designed for more expensive types of wood.

The only disadvantage of this material is that it cannot be used for underfloor heating. In this case, it is better to use bitumen varieties.

How to lay underlayment under laminate correctly

We've sorted out the materials. Analyze the available topcoat, and based on this, choose the best type for it. To figure out how to properly lay a laminate underlayment, we offer a step-by-step guide. Since the most common option is polyethylene foam, let’s take it as a basis.

We've sorted out the materials. Analyze the available topcoat, and based on this, choose the best type for it. To figure out how to properly lay a laminate underlayment, we offer a step-by-step guide. Since the most common option is polyethylene foam, let’s take it as a basis.

- Level the floor. As already mentioned, the substrate is not able to replace the leveling with other materials.

- Wait for the concrete to dry completely.

Important! Working on wet or damp concrete is prohibited.

- Remove any remaining debris and dust.

- Roll out the roll of backing along the wall where installation will begin. To begin, lay two or three rows.

Important! The underlay should be laid gradually, from wall to door. It's better not to walk on it.

- Place the sheets of backing tightly together and seal with construction tape.

On a note! If you choose polyethylene foam, which is ribbed on one side, you should lay it with the ribbed side down.

All! The underlay has been laid and the floors are ready for further finishing.