Laminate underlay thickness

Even if the base for laying the laminate seems perfectly flat, the presence of the substrate cannot be ignored. It allows you to make the floor truly flat, prevents the lock from breaking or the formation of depressions in the board, and also helps improve noise and heat insulation. Its thickness, like the board itself, can be different. Let's figure out which one is needed in individual cases.

Even if the base for laying the laminate seems perfectly flat, the presence of the substrate cannot be ignored. It allows you to make the floor truly flat, prevents the lock from breaking or the formation of depressions in the board, and also helps improve noise and heat insulation. Its thickness, like the board itself, can be different. Let's figure out which one is needed in individual cases.

The content of the article

What determines the thickness of the substrate under the laminate?

The thickness depends mainly on the material of manufacture. The most popular are the following:

Foamed polyethylene. This is the most popular material. It has a low price and good characteristics. Thus, polyethylene is not afraid of moisture and is a good heat and sound insulator. Its thickness is usually small.

Foamed polyethylene. This is the most popular material. It has a low price and good characteristics. Thus, polyethylene is not afraid of moisture and is a good heat and sound insulator. Its thickness is usually small.- Polystyrene. It is made with foil on one side. This is a more expensive material, but it has better performance characteristics. Does not accumulate moisture, does not allow mold to form, and sags less. Its thickness is slightly higher.

- Cork is considered one of the most expensive. It does not sag at all, has higher qualities of noise and heat insulation, is quite thick in properties, and is durable. Suitable for high quality laminate.

The choice of backing thickness is influenced by such indicators as:

- level of base roughness;

- floor operating conditions;

- price policy;

- required level of noise and heat insulation;

- price and quality of laminate.

Now let's take a closer look at the existing thickness options.

Types of substrates and their thickness

Since the main difference in thickness depends on the type of product, this will be one of the main division criteria. Above we named the main materials from which this coating element is made. These are the most popular options, however, they are not the only ones. There are other bases from which the laminate underlay is made. Let's divide them according to the criterion of thickness.

Since the main difference in thickness depends on the type of product, this will be one of the main division criteria. Above we named the main materials from which this coating element is made. These are the most popular options, however, they are not the only ones. There are other bases from which the laminate underlay is made. Let's divide them according to the criterion of thickness.

Minimum - 2 mm

This is the subtlest variation. It is suitable in cases where surface unevenness is minimal. Basically, the 2 mm backing is foamed polyethylene. It meets the minimum requirements:

- provides a minimum level of isolation;

- does not accumulate moisture;

- not susceptible to rodent damage;

- does not mold.

It also has a low price, which largely ensures its popularity. The disadvantages include a high degree of subsidence.

Important! A 2 mm underlay is only suitable if the base has minimal unevenness.

Standard - 3 mm

This option is represented by a mixture of polyethylene and polystyrene, which is located between two layers of the first material.

This is the most popular option. Suitable for good insulation, completely smoothes out all floor irregularities and sags less.

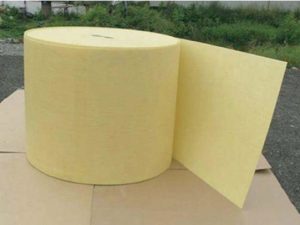

Cork backing 4 mm

The 4 mm substrate is mainly represented by cork options. It can be pure cork, bitumen-cork or rubber-cork. This series belongs to the more expensive options, but it has more advantages in addition to the above:

- does not sag;

- non-flammable;

- light;

- environmentally friendly;

- durable.

Due to its non-flammability, this material is often used when installing heated floors. Suitable for leveling both small and more noticeable irregularities.

Which substrate is 5mm

It is represented by fiberglass, covered on one side with a bitumen plug. Suitable for leveling deeper unevenness. It has excellent sound, heat and waterproofing properties.

Important! A 5 mm underlay is placed with gaps around the perimeter of the room.

Expanded polystyrene 7 mm

Above was the 3 mm model, which is a combination of polystyrene and polyethylene. In this case, the composition includes only foamed polystyrene.

On one side, such a canvas is made of corrugated material, which improves insulating properties and also prevents the accumulation of moisture and the formation of mold.

Important! To fasten such a substrate, adhesive tape is not enough; adhesive aluminum tape is used here.

What is 10 mm underlay

This option is used quite rarely, since this is the maximum thickness of the substrate. In some cases, it can replace the use of self-leveling mixtures. Represented by tiles made of pine needles. It is made mainly to order, and it is extremely difficult to find it in stores.