The junction of laminate and linoleum

There are often times when we need to join materials of different heights (linoleum and laminate). In modern times this is possible thanks to thresholds. There are several varieties, so you need to choose based on the characteristics of the coating.

There are often times when we need to join materials of different heights (linoleum and laminate). In modern times this is possible thanks to thresholds. There are several varieties, so you need to choose based on the characteristics of the coating.

The content of the article

How to properly join laminate and linoleum

Thresholds are required for docking. They differ from those thresholds that are attached to the door in their functionality and complexity. The problem concerns not only the fact that it is difficult to do quality work. The joints also look ugly. This spoils the interior, because they are very noticeable.

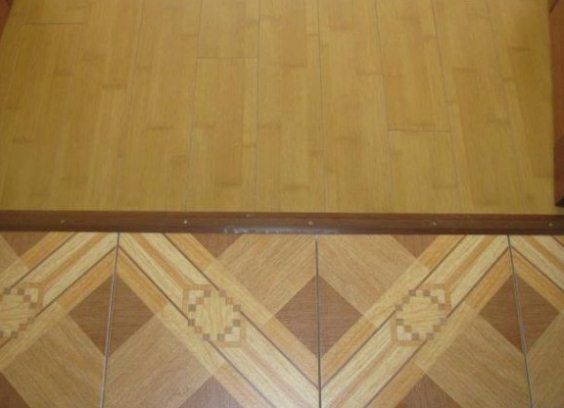

Reference! It is quite difficult to create a connection between these materials. This is due to the different thickness of the materials (laminate is thicker than linoleum). Therefore, it is important that the joint is not visible.

There are 2 ways to join materials:

- Level the linoleum so that it is flush with the laminate.

- Seal the joint using aluminum strips, sills or other elements.

Important points

There are some requirements that thresholds must satisfy:

- Waterproof. The profiles connecting the joints must be cleaned of water, as it causes deformation and rotting.

- Resistant to sudden changes in room temperature.

- UV protection. If the material is not protected, it will begin to fade when exposed to sunlight.

- Easy to install.

- Durability and wear protection. Profile properties should not change over time.

- The fasteners should not be visible.

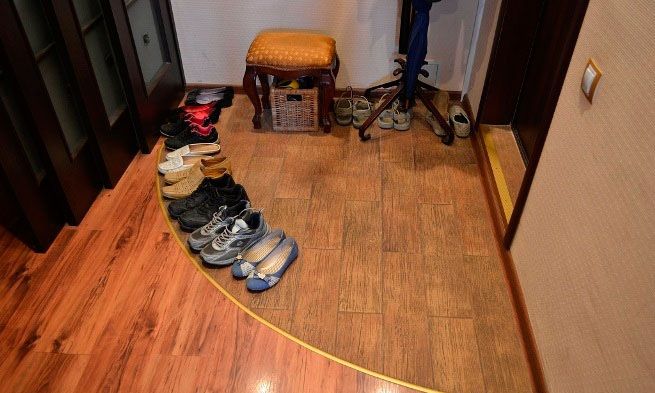

- Possibility of docking, regardless of the curvature of the floor.

- Ability to process material (for example, trim excess).

- The ability to use a joint even if the difference in the height of the materials is two millimeters.

- The bending radius when heating is up to 30 cm, and when cooling is up to 60 cm.

- Possibility of repairs.

- Possibility of installation on already laid coverings.

Single-level joints

If we consider this joint as the most beneficial for the interior, it is considered better. Connections are made using professional moldings and other overlay options.

For single-level docking, it is necessary to lay high-density material under the first one. Its thickness is approximately equal to the difference between the heights of the products. For such cases, plywood (preferably multilayer) is suitable. For a doorway, it is better to choose this option, since it is better to combine materials in this way.

Multi-level joints

This option is suitable if you need to level a floor whose height has become different due to a combination of different coatings (linoleum and laminate). For this purpose, special thresholds were created:

- Direct. Allows joining of single-level floors.

- Transitional. Allows you to connect two different levels.

- Final ones. Suitable if you need to decorate the edges of coverings.

- Angular. Will be needed if you need to connect linoleum and stairs.

Reference! Such products are sold in almost every hardware store. But before buying, you need to choose the material.

Thresholds are made from the following:

- Metal.

- Plastic.

- Cork.

- Rubber.

- Wooden.

- Laminated.

All of the materials listed above have a different appearance. Therefore, you can create a design for any room. The color and width are also different. Therefore, you need to choose based on quality. The characteristics listed above play an important role here. For example, wooden ones are poorly protected from moisture and need to be treated with solutions. But rubber ones are completely waterproof, but their strength is slightly lower.

Fastening thresholds and strips at joints

The joints are connected using thresholds and strips. The mounting options are as follows:

- Through. The connecting profile is applied over the materials. The panels are mounted to the floor using self-tapping screws.

- Secret. We use fastening strips, on the back of which there are grooves. The front side is flat. Thanks to this, the material can be joined by hiding the fasteners. This will allow the transition at the same level.

- Using gluing instead of joining. This method is used less frequently, since it can only be used in rooms with low load on the floor (high load will lead to damage to the joints). You can use glue or liquid nails.

The problem with different heights is easy to solve thanks to the thresholds. Choose the ones that suit your case.