What to lay laminate on a wooden floor

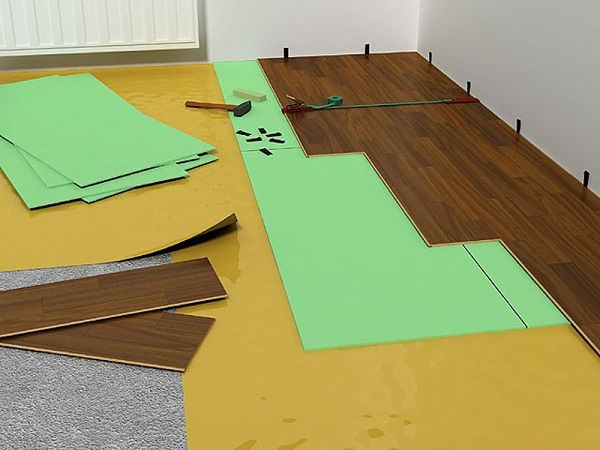

Very often people lay laminate flooring. But before installation, it is necessary to make a substrate. It will allow the laminate not to come into contact with the floor, and avoid problems with thorny materials.

Very often people lay laminate flooring. But before installation, it is necessary to make a substrate. It will allow the laminate not to come into contact with the floor, and avoid problems with thorny materials.

The content of the article

How to level a wooden floor before laying laminate

There are 3 ways to level the floor:

- Laying sheet material.

- Creating a wet screed.

- Cycling (suitable if the unevenness is minor).

Looping is the most common leveling option. We need:

- Drive the fastening nails into the floor well.

- We cover the cracks with putty. We are waiting for it to dry completely.

- Sanding the floor. The process will produce a lot of dust and chips. We delete them.

- You can lay laminate.

The second option is laying sheet materials. The floors are covered with plywood or chipboards. They are mounted using self-tapping screws. We treat with solutions to remove moisture.

Wet screed is covering the surface with a layer of concrete. Of all the alignment options, this is the most effective. But be careful, a wooden floor may not be able to withstand the load of heavy concrete. You also need to know what to lay on this floor so that the laminate does not deteriorate.

Choosing a laminate underlay for an old wooden floor

After treating the surface, you cannot immediately lay laminate on it. First, the substrate is created. It has the following functions:

- Creating a layer of thermal insulation.

- Blocks the spread of sounds.

- Does not allow the wooden floor to deform.

- Does not allow the floor and laminate to come into contact. Thanks to this, they will not wear out or wear out.

The following products can be used for the substrate:

- Roll of cork.

- Good quality linoleum.

- Polystyrene.

- Fabric based on geotextile materials.

- Polyurethane.

Some people use plywood or particle boards as a backing. But these materials have disadvantages:

- Materials are severely damaged when in contact with water.

- They constantly need to be treated with solutions.

- Poor ventilation.

- The appearance of fungus and mold.

If the load on the room is too high, a combination of two underlays that need to be placed on the floor is a good idea. For example, polyethylene and expanded polystyrene. One layer will isolate sounds, and the other will provide good thermal insulation. The underlay is glued to the floor.

From polyethylene foam

The most popular option on the market due to the good quality-price ratio. The material is made of metal-based film and aluminum foil. The advantages are as follows:

- Good protection against moisture.

- Biostability.

- Thermal insulation.

Flaws:

- Deforms under the influence of ultraviolet radiation.

- Sags quickly.

Attention! When choosing a material, you need to pay attention to the density (the higher, the better the interlayer). This also affects the shelf life. If the thickness of the panels is about 1 cm, the thickness of the polyethylene foam should be at least 0.3 cm.

Made from polystyrene

The material has good characteristics. The underlayer is made of two layers (polystyrene and aluminum foil). Its advantages:

- Affordable price.

- Not subject to the appearance of fungus and mold.

- Protected from moisture.

The disadvantages are the following:

- Difficult to roll out during installation.

- Compresses under heavy load.

Cork

The cork backing is based on pressed oak bark chips. This material can be made only from wood, or can be combined with rubber or bitumen. The advantages of the substrate are as follows:

- Good rigidity. Strong loads are not able to compress the material.

- The wood is natural and safe.

- Well insulates heat and sounds.

- It will last for hundreds of years.

- Biostability.

- Allows you to disguise uneven floors.

Reference! But this material has a significant drawback - the wood rots when exposed to water. Therefore, it is not recommended to use it in rooms with high humidity (bathroom, kitchen) or in rooms with heated floors.

Which substrate is better

Each substrate has advantages and disadvantages. You need to make a choice taking into account the characteristics of the room. For example, cork will be ideal for the living room and bedroom, but not suitable for the kitchen and bathroom. Polystyrene is also a good option for the bedroom, but is not suitable for the corridor and hallway (the material shrinks under load). Polyethylene foam is ideal for the bathroom and kitchen (moisture resistant), but is not suitable for the corridor (settles due to loads).

The underlay is needed not only to protect the laminate from deformation during friction against the floors. It also performs many other functions, such as protecting the material from moisture, heat and sound insulation. Therefore, it must be chosen carefully; not all options have the characteristics we need.