DIY laminate furniture

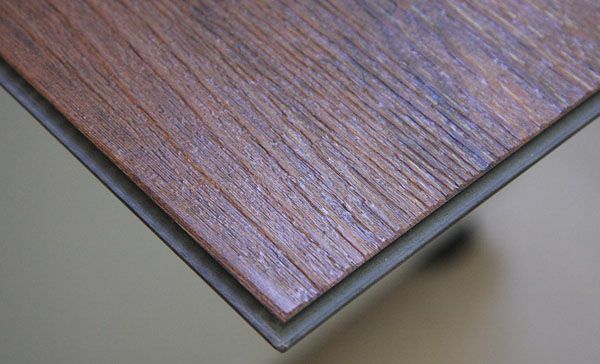

Laminate is a universal material, made from pressed sawdust with the addition of formaldehyde resin. The plate is formed at high temperatures. The color coating of laminated chipboard is a melamine film (paper impregnated with resin) coated with a durable varnish. The material is used for finishing premises, in the manufacture of decorative elements and in the production of furniture.

Laminate is a universal material, made from pressed sawdust with the addition of formaldehyde resin. The plate is formed at high temperatures. The color coating of laminated chipboard is a melamine film (paper impregnated with resin) coated with a durable varnish. The material is used for finishing premises, in the manufacture of decorative elements and in the production of furniture.

Laminated chipboard is divided into three types based on resin content and sawdust quality. The first type is the most environmentally friendly. Sawdust is made specifically for laminate flooring. It is more expensive than other options. Laminate is great for making furniture at home.

The content of the article

Features of laminate, its advantages and disadvantages

Before you start working, you need to understand what a chipboard is.

Before purchasing a material, you should ask the seller about its characteristics and ask for a certificate. High-quality laminate is manufactured according to European standards; the amount of resins should not exceed 8 percent of the total composition. Class E1 (F1) is manufactured in accordance with GOST 10632-89 and is suitable for the production of furniture in any room. Classes E2 and E3 are not recommended for use in the manufacture of children's furniture (it would be better if the laminate of these brands is not in the house at all).

Advantages of laminate:

- withstands elevated temperatures and loads;

- has a rich color palette;

- easy to use;

- There are moisture-resistant options, the width of the slab in this case should exceed 38 mm (suitable for countertops on kitchen units and tables).

ATTENTION! When making long shelves, you should remember that over time the laminate sag, so it is necessary to install supports.

The color range includes:

- Solid colors - there are smooth or with patterns that will collect dust.

- Painting imitating wooden cuts (cherry, beech, oak).

- Glossy surface - if the chipboard is less than 22 mm wide, it is not recommended to cut deep hinges; the surface will crack.

- Fantasy elements - flowers, patterns, geometric designs.

REFERENCE! If you decide to purchase furniture made from moisture-resistant laminated chipboard, measure the width with a ruler; often manufacturers glue several sheets together and cover with an edge (the gluing will be a multiple of 10 or 16 mm).

Disadvantages of laminate:

- when exposed to moisture, sawdust gradually swells;

- models of classes 2 and 3 have a lot of formaldehyde, which are hazardous to health;

- there is no possibility to produce carved elements;

- cannot be milled.

How to make laminate furniture with your own hands

To make furniture, you first need to select a model and make an accurate drawing of the future product. This will make it easier to select the material and its quantity.

IMPORTANT! It is recommended to buy laminated chipboard from a large supplier that offers board cutting services (a drawing will help here). It is almost impossible to make a cut accurately at home, since this operation is performed on special machines.

Necessary tool

Before you start work, you need to select the tool with which the furniture will be made:

- Drill - necessary for making holes. A special furniture drill is required for the hinges of opening doors.

- Clamps - the tool is a fixing mechanism, differs in the type of carpentry tasks. Needed to secure parts together.

- A screwdriver will make the task of screwing in self-tapping screws easier (you can use a screwdriver).

- Measuring instruments - ruler, level, pencil, tape measure.

IMPORTANT! Before starting work, you need to select the necessary fittings (screws, hinges, guides, eccentrics, legs, handles), and also purchase fiberboard sheets (for the back wall).

Stages of work

It must be remembered that the ends of the laminated chipboard are equipped with an edge. You won’t be able to do this at home using a hair dryer. The edge is glued on a special machine. It is recommended to carry out this stage of work from the seller or furniture production:

- Tools and accessories should be carefully laid out. Place or hang the drawing in a convenient place. Disassemble the chipboard parts.

- It is necessary to mark the places where fasteners, hinges, shelves, etc. will be located.

- Make holes for screws and hinges.

- First you need to fasten the large parts. For cabinets, these are the walls, bottom and top of the product. The beds have a box and then walls.

- The sides need to be tightened so that the furniture does not “walk”. It is better to install the screed on top of the fiberboard (or back wall).

- Assemble the internal parts of the product: shelves, drawers (they can be assembled first), fastenings (including runners for compartment doors).

- Place the furniture on a support (legs, plinth, thrust bearings).

- Install facades. They are installed last.This is necessary in order not to damage the front part during assembly.

It should be remembered that laminate is a rather heavy material. Therefore, it is recommended to make the side walls of large products from chipboard with a thickness of 22 mm and higher.