DIY bird feeder made of laminate

You may still have pieces of laminate left after the renovation. In order not to throw them away, we will find a use for them. They won't last as shelves, and the leftovers usually come in small quantities. But making a bird feeder out of laminate is a great idea. It’s good for both the feathered friends and a joy for the child.

The content of the article

Basic rules for building a bird feeder

Before you get started, you need a little theory. If you want to complete the task quickly and get a quality product, the best option would be a feeder house. Why?

- Reason #1 – the lid. To prevent snow from covering the food, it is necessary to build a roof. The model we have chosen fits this criterion. The roof also protects food and smaller birds from larger birds.

- Reason #2 – sides. This element is necessary to prevent the wind from blowing the treat away. And also to prevent large birds from getting inside the feeder.

So, the feeder must be protected from weather conditions, as well as from cats and large birds.

We build a laminate bird feeder with our own hands

Now you can start making a feeder from improvised materials. To begin with, you should prepare your workplace. If you plan to work in an apartment, it is better to move the process to the balcony.If this is not possible, try to keep sawdust from getting on the carpet, sofa and other soft surfaces.

Now you can start making a feeder from improvised materials. To begin with, you should prepare your workplace. If you plan to work in an apartment, it is better to move the process to the balcony.If this is not possible, try to keep sawdust from getting on the carpet, sofa and other soft surfaces.

On a note! It is better to immediately prepare a vacuum cleaner and remove dust and sawdust several times during the work process.

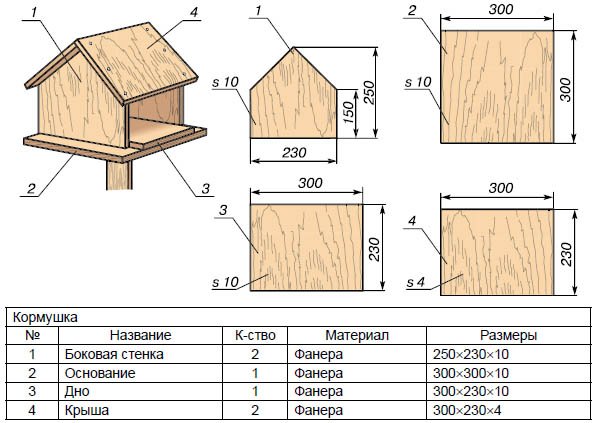

Feeder drawing

If you really take the matter seriously, you need to prepare a drawing of the future product with dimensions. But this stage can be simplified by simply drawing a sketch.

On a note! You should not skip the drawing stage; it is better to have either an accurate representation of the future product or a sketch.

In the sketch, indicate the dimensions of all elements. Then you will cut them according to measurements and avoid inaccuracies and inconsistencies in the future product.

Preparatory stage

At this stage, you need to prepare everything you need for future work. Prepare the following tools:

nails or screws;

nails or screws;- hammer or screwdriver (depending on the selected fastening elements);

- jigsaw or saw;

- grinding machine or sandpaper;

- masking tape;

- wood varnish.

Also prepare laminate boards and ordinary wooden boards, or lining.

Important! The sides should be made of thick boards of natural wood for comfortable fastening.

The tools and materials are ready, now you can begin to directly create the feeder.

Preparing the components

In accordance with the dimensions indicated in the drawing, cut out the necessary elements. As a result, you should get:

rectangular bottom.

rectangular bottom.- two low sides along the bottom length (Important! They should be smaller by the width of the other side for easy connection).

- two high sides with a triangular top along the width of the bottom.

- two pieces of laminate for the roof.

Sand all the resulting parts, removing nicks, irregularities and roughness.If possible, treat the wood with a special moisture-repellent agent.

Final stage

Now let's move on to assembling the parts.

Using nails or self-tapping screws, attach the low sides to the bottom.

Using nails or self-tapping screws, attach the low sides to the bottom.- In the same way, fix the high sides, and also secure them together.

- Attach the laminate “roof” to the side wall with a small self-tapping screw.

- Attach the second roof flap.

- Secure the “roof” parts together with masking tape.

Now you can varnish the feeder. If desired, it can be painted or painted.