What you need to lay laminate flooring

Laminate came to the construction market relatively recently, but has already won the love of many apartment owners. The fact is that it combines low cost, durability and ease of installation of flooring. But in order for the assembly of the flooring to meet expectations and not turn out to be a troublesome task, it is still necessary to prepare a little for it.

The content of the article

What you need to prepare for laying laminate flooring

Installation of lamella flooring is just the final stage of the work. After all, before this it is necessary to tidy up the subfloor - this is the only way to avoid many problems during the operation of the laminate and significantly extend its service life. This involves repairing the base and eliminating its unevenness. As an option, during finishing preparation you can use self-leveling mixtures based on:

- cement, gypsum, fine sand and plasticizers - for concrete floors;

- synthetic fibers, polymers and fiberglass - for wood.

REFERENCE. Before leveling, it is important to identify all weak points of the rough coating and repair them. After completion of the preparatory work, the permissible unevenness of the floor is 2 mm per 2 m2.

It is also recommended to carry out adaptation seasoning of the “boards” in the room before laying.To do this, you need to print out the ends of the packaging and leave the laminate for at least two days in the room in which it will be installed.

What tools are needed

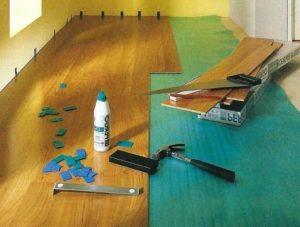

All tools used when working with lamellas can be divided into 2 groups:

- basic - without which proper installation is impossible;

- auxiliary - its absence is compensated by greater labor costs and attentiveness.

The first group includes:

- tape measure, square, pencil - for measurements and making marks;

- jigsaw - for cutting lamellas, a tool with a power of about 500 W is sufficient;

- hammer and boss (wooden block) - to ensure the locks click without damaging the slats;

- clamp - to press the outer row when there is not enough room for hammering.

The auxiliary ones include:

- restrictive wedges, without which it is difficult to maintain the correct compensation gap between the laminate and the wall;

- masking tape - for gluing the canvas before cutting in order to mark and prevent the formation of chips;

- glue or sealant - can be useful for additional fixation and waterproofing of simple locks;

- a dustpan and a broom, without which it is impossible to keep the rough foundation clean;

- building level - for constant monitoring of the correct connection of the lamellas.

This list may be supplemented depending on the installation features of the skirting boards and underlay

What materials to prepare

Much depends on the foundation. So, when laying laminate flooring on concrete, it is necessary to take care of laying a vapor barrier, which can be a simple polyethylene film. But its use on a wooden base is prohibited - this will lead to damage to the entire floor.

Also, the thickness of the substrate depends on the quality of the rough base. Its task is to heat and sound insulate the laminate. At the same time, it can smooth out minor irregularities in the finishing screed. However, sometimes they try to use the substrate as a coating to compensate for serious defects in the base. To do this, choose a material with a thickness of over 3 mm, which leads to the appearance of extraneous squeaks during the operation of the laminate.

REFERENCE. Regardless of what the substrate is made of, its thickness should not exceed 3 mm. Reason: elasticity of the material. A layer that is too thick will not compensate for the shortcomings of the subfloor, but will only increase their impact on the laminate - the slats will sag under load even on a perfectly flat surface due to the compression of the soundproofing cushion.

To prevent the slabs or substrate strips from moving during the installation process, they are fastened together with simple tape. But if a rigid plywood base is prepared for the laminate, then it is secured to the subfloor using dowels and self-tapping screws. In this case, a drill with drill bits will also come in handy. When installing a heated floor, in addition to the heating system, you will also need ordinary foil - it reflects heat into the room several times more efficiently than foil substrates.