How to make a mirror from glass

At all times, the mirror was endowed with a special magical power, capable of remembering everything that was reflected in the smooth surface. That is why this attribute was most often passed on from generation to generation, lingering for a long time in one family. Special craftsmen preferred to make the mirror themselves so that it would carry only one energy - that of its master.

Today, making a mirror yourself is not particularly difficult.

The content of the article

What materials and tools will be needed to make a glass mirror?

A handmade mirror will not only become an interior item, but will also bring special charm and uniqueness to the room. All materials for its manufacture are available to anyone. However, you will additionally need some chemical reagents, which are also not difficult to find.

A handmade mirror will not only become an interior item, but will also bring special charm and uniqueness to the room. All materials for its manufacture are available to anyone. However, you will additionally need some chemical reagents, which are also not difficult to find.

In order to make a glass mirror, you need to have some chemical reagents, means to protect exposed skin, mucous membranes and eyes, and glass.

How is production carried out?

First of all, you should decide on the glass from which the mirror will be made. Window glass, carefully removed from an outdated frame, is also quite suitable for this. Both purchased glass and window glass must be perfectly smooth.

First of all, you should decide on the glass from which the mirror will be made. Window glass, carefully removed from an outdated frame, is also quite suitable for this. Both purchased glass and window glass must be perfectly smooth.

No damage such as scratches or chips is allowed.They can negatively affect the reflection quality of future glass.

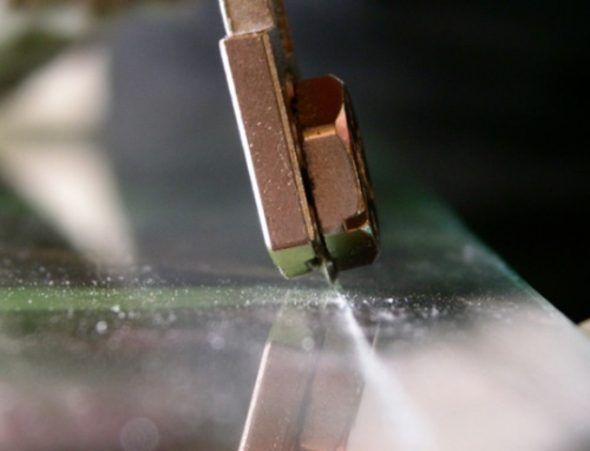

How to make a mirror from glass? Next comes cutting the existing canvas to the required shape. To do this, you can use a cardboard form.

IMPORTANT! Working with glass requires special skill and skill. To do this, it is better to use a special glass cutter. In addition, you should not forget about your own safety - you should protect your eyes with special glasses and your hands with gloves.

After the glass base is prepared to begin work, the silvering stage follows.

To give glass the ability to reflect objects, it must be silvered. For this you will need:

- Body protection, namely rubber gloves, goggles and a mask, from contact of chemical reagents on exposed skin;

- Detergents;

- Water, without any impurities;

- Potassium hydroxide 15%;

- Ammonia 25%;

- Formalin;

- Nitrogen silver;

- Scales.

Reference. All chemicals can be purchased both through online stores for young chemists and in city pharmacies.

Before starting work, the glass surface is thoroughly cleaned with water and detergents. After this, it is necessary to remove all remaining water from the glass with a soft cloth that does not leave any streaks. A solution of potassium hydroxide is necessary to completely degrease the working surface of the glass.

To completely clean the glass from dust and other small particles, it must be placed in a container filled with distilled water.

After this, you should begin preparing the solution necessary to create a mirror layer. To do this you need to mix:

- 30 ml purified water;

- 2 grams of silver nitrate.

All this is mixed well, after which ammonia is introduced into the solution drop by drop until the existing precipitate is completely dissolved. After this, add 100 ml of water and leave the solution in a dark place for 15–20 minutes. After the solution has settled, 5 ml of formalin is added to it.

In order to apply the mirror solution to the product, you will need a bathtub or deep basin. The chemical solution is poured onto the cleaned surface and left on it until completely dry. The remaining solution is washed off with warm water. To strengthen the mirror layer, you can use varnish. This way the mirror will last much longer without any damage.

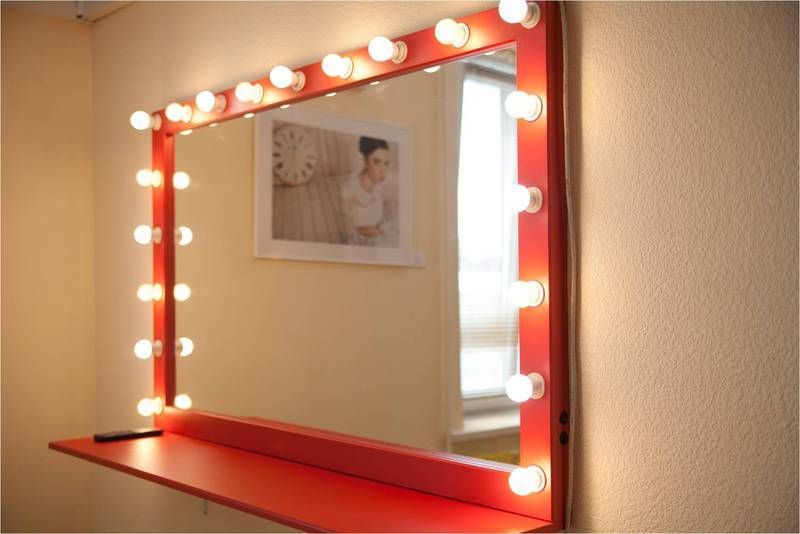

How to choose the right frame

Frames for the finished product can be very diverse. The simplest option is to apply black paint along the edge of the mirror, possibly depicting some kind of design. For a more solid frame, metal, plastic or wood are suitable.

Frames for the finished product can be very diverse. The simplest option is to apply black paint along the edge of the mirror, possibly depicting some kind of design. For a more solid frame, metal, plastic or wood are suitable.

The stores have a wide variety of frames, from carved wooden to forged. In addition, you can order the manufacture of a mirror frame according to your own sketch in a special workshop. In this case, the product will turn out to be truly unique and inimitable.