DIY sink cabinet

Any consumer wants to recreate the author’s style in the bathroom, making it not only visually attractive, but also quite functional with the help of a variety of furniture. One of the options for furniture products is a do-it-yourself bathroom vanity cabinet. This type of furniture can have different shapes, sizes and a lot of functionality.

And what’s most important is that any user can make these cabinets with his own hands. And we decided to talk about this below, providing you with detailed manufacturing instructions.

The content of the article

Determining the parameters of the sink cabinet

At the moment, there are many options for making a bathroom cabinet. But when choosing parameters, it is recommended first of all to start from financial capabilities. Also, a decisive role should be given to the functions of the item and its style, the dimensions of the bathroom, and, of course, the personal preferences of the household.

At the moment, there are many options for making a bathroom cabinet. But when choosing parameters, it is recommended first of all to start from financial capabilities. Also, a decisive role should be given to the functions of the item and its style, the dimensions of the bathroom, and, of course, the personal preferences of the household.

In addition, the main criteria for making a washbasin cabinet with your own hands include:

- Appearance;

- Location;

- Installation method;

- Material of manufacture.

Selection of materials

The service life will depend not only on the quality of the work performed, but also on the material of manufacture.Based on the information provided, a do-it-yourself bathtub sink cabinet can be made from:

The service life will depend not only on the quality of the work performed, but also on the material of manufacture.Based on the information provided, a do-it-yourself bathtub sink cabinet can be made from:

- Natural wood;

- Glass;

- Plastic;

- Drywall;

- MDF.

The do-it-yourself sink cabinet made of natural wood has a presentable appearance and will delight you with a long service life, due to the presence of protection in the form of a special moisture-resistant coating. But the cost is a bit steep, which forces consumers to look for an alternative. And one of these options is MDF.

To make a sink cabinet with your own hands from glass, you will need to have skills in working with this material. And therefore, only specialists can make such structures. But plastic is perhaps the best option. It is ideal for any bathroom and requires minimal effort when working with it.

In addition, this material is resistant to moisture. The situation will be similar when using drywall.

A stylish product can be achieved by using several materials at the same time. This way you can get a practical, economical and, most importantly, a universal vanity cabinet in the bathroom.

Instructions for assembling a cabinet with your own hands

How to make a cabinet under the sink? Before you do it yourself, you will need to carry out a number of preparatory steps. Initially, it is recommended to determine the location of the future structure, and also pay attention to checking the water and sewer pipes.

How to make a cabinet under the sink? Before you do it yourself, you will need to carry out a number of preparatory steps. Initially, it is recommended to determine the location of the future structure, and also pay attention to checking the water and sewer pipes.

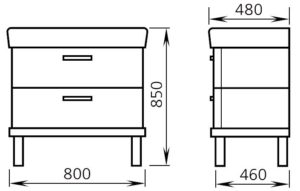

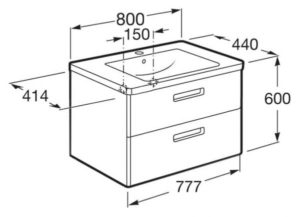

In addition, it is necessary to choose the appropriate dimensions of the cabinet based on the size of the washbasin, and consider the method of fastening. And then you can select the material of manufacture, create a drawing and proceed directly to the main part of the work process.

Preparing parts

At the initial stage, it is necessary to prepare all the components of the future structure. Based on the drawing, we apply the appropriate markings to the purchased material, and then use a suitable tool to cut it out.

At the initial stage, it is necessary to prepare all the components of the future structure. Based on the drawing, we apply the appropriate markings to the purchased material, and then use a suitable tool to cut it out.

To cut holes in the cabinet under the sink, you will need to use an electric jigsaw, and the size of the hole must be determined using a pattern, which can be made from cardboard, leaning it against the sink, and applying the necessary markings using a pencil.

Attention! The resulting hole must completely follow the contours of the bottom of the washbasin.

Next you will need to cut out the trim for the top. During the process, it is necessary to take into account the size of the doors so that they do not come into contact with the top when opening. And after that you can proceed to installing the bedside table.

Product installation

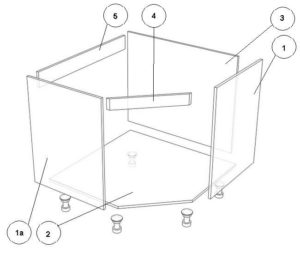

First, you will need to assemble the frame of the future product, and only then proceed with the installation of the remaining parts of the future structure. In this case, you will need to process all the side cuts, which will help prevent moisture from entering. For these purposes, it is recommended to use moisture-resistant glue, and before processing, the sections should be cleaned with sandpaper and primed with waterproof products.

First, you will need to assemble the frame of the future product, and only then proceed with the installation of the remaining parts of the future structure. In this case, you will need to process all the side cuts, which will help prevent moisture from entering. For these purposes, it is recommended to use moisture-resistant glue, and before processing, the sections should be cleaned with sandpaper and primed with waterproof products.

Then we attach the side parts to the frame using self-tapping screws, having previously marked holes for them. Then we install the tabletop, attach the doors and, if necessary, install internal drawers. At this point, the assembly of the product is completed, and all we have to do is install the sink on the resulting product.

Before this, it is necessary to connect all the water pipes to the mixer, and only then install the sink on the prepared “platform”.To ensure that the washbasin is securely attached and does not get mixed up with light force, it is recommended to apply silicone to the edge of the cabinet before installation.

After placing the sink, simply install the cabinet against the wall in the chosen location, and treat all connecting seams with silicone sealant. After drying, you can begin tiling and decorate the cabinet according to your personal preferences.