DIY kitchen sink cabinet

In addition to the fact that kitchen furniture carries a functional grain, it is also a design element. And if you get puzzled and make it yourself, this will allow you not only to take away a piece of bread from the designers, but also to rise in the eyes of your household.

To make a sink cabinet, you can choose a variety of materials. The shape can also be different. It is not at all necessary to follow the standard and make the furniture rectangular. In addition to the fact that the cabinet will hold the sink, you can arrange additional drawers inside, place a water tank and much more. Naturally, everything needs to be thought out in advance and a sketch prepared.

The content of the article

Variety of appearance and design features of sink cabinets

When thinking about how best to arrange all the components of the headset, you have to rely on the size of the room. You always want to fit as much as possible into a limited space. You can arrange furniture in different ways. You can put everything in one row or in the form of the letter G or P, create an intricate pattern.

How all the furniture in the kitchen will be arranged will depend on how and where the stove and sink are located. If you plan to make a cabinet yourself, then first of all think about what shape will be easier for you to make. Sinks come in the following forms:

- Rectangular or straight. The simplest option in terms of manufacturing. It is believed that it is more convenient to place all pieces of furniture along one of the walls of the room. Between them there will be a work table-cabinet, perhaps even a refrigerator can be placed. A single tabletop for all elements of the set looks very unique. The beauty is that with this option there is no need to make the top part of the cabinet. You can even simplify your task and buy ready-made facades.

- Corner cabinets. They are installed in the corners of the room. Among them, several subspecies stand out - in the form of the letter G, triangle and rectangular. Such models take up little space in the room. This is precisely what is important if the kitchen is not particularly large. If you approach the issue of using the space inside the cabinet correctly, then you can install a lot of things there. If you additionally equip all this with shelves and a carousel, then this option will deserve attention. It will take a little more time to create compared to rectangular furniture, but obviously not more difficult.

- Trapezoid cabinet. This model has a very wide tabletop, its drawers are quite spacious. Thanks to this shape, sinks of various shapes can easily be placed on it. The only thing is that it requires a lot of space.

Required materials and tools for assembly

Most often, laminated chipboard is used to make kitchen furniture. Due to its coating, this material is not very afraid of dampness.

If the choice fell on this, then you will need to purchase an edge tape that prevents the evaporation of the aldehyde resin that is included in its composition. This substance is very harmful to humans.

A good option would be to use natural wood. But it has significant drawbacks - it costs much more, water is well absorbed into it and it is difficult to care for. However, all the shortcomings, except the price, can be eliminated.

Once the material has been selected, it’s time to prepare the tool and additional accessories:

- for the back you need to purchase fiberboard;

- for internal partitions - plywood;

- tape for cladding - it must be selected in accordance with the main color of the cabinet;

- hinges, door handles, screws and corners.

To work you will need to stock up on the following tools:

- for marking you need a pencil, for measurements - a ruler or tape measure;

- You will need an electric drill, a cordless screwdriver;

- figured screwdriver;

- electric jigsaw.

Making a sink cabinet with your own hands

In the entire procedure of working on a sink, the following stages can be distinguished:

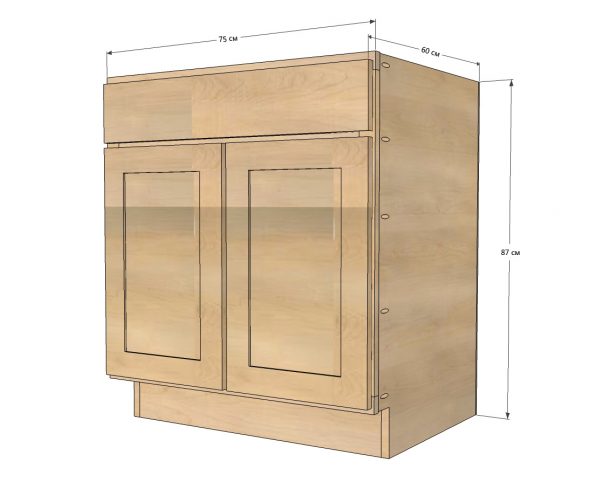

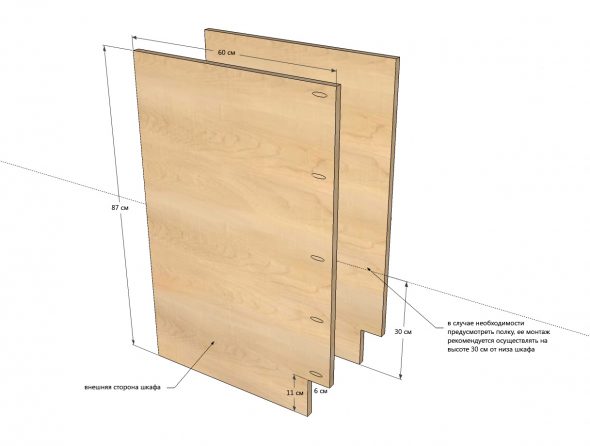

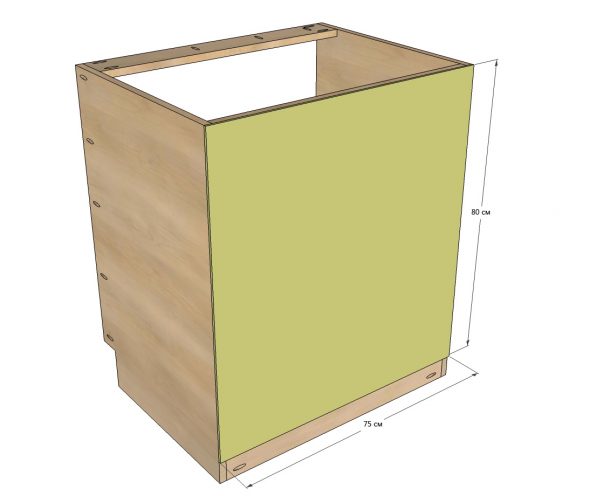

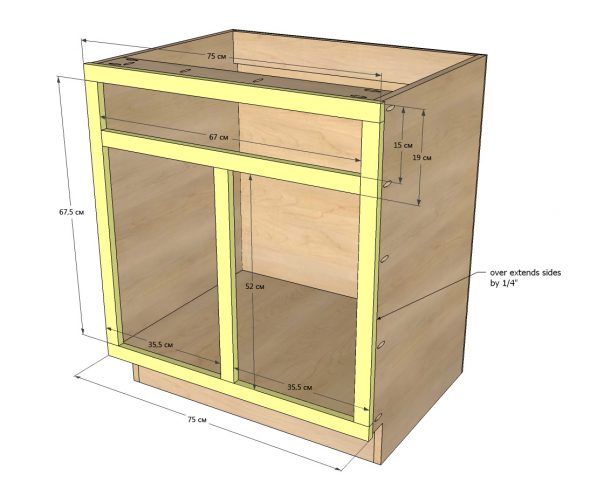

- Preparatory part. Initially, a drawing of the future product is developed, and the necessary dimensions are applied to it.

- Preparation of individual structural elements. But based on the drawing we cut out the walls for the side parts, the bottom part, and also the doors. If the sink is a countertop type, then there is no need to make a countertop for the cabinet. If this is a mortise option, then the outline of the sink is drawn on the countertop, after which a hole is cut with an electric jigsaw. We cut out all other parts in the same way with a jigsaw. After everything is ready, it is recommended to sand the edges.

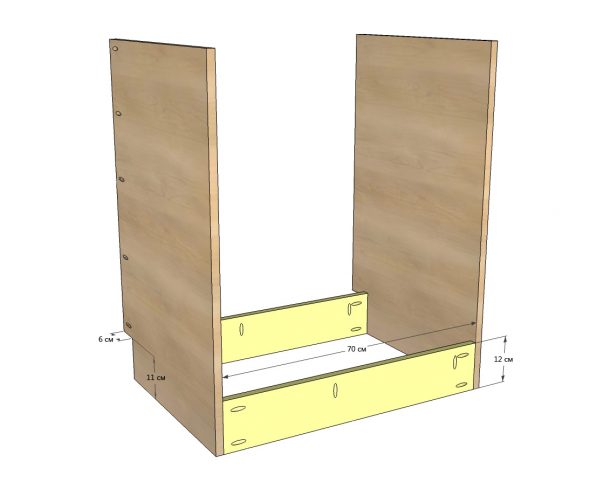

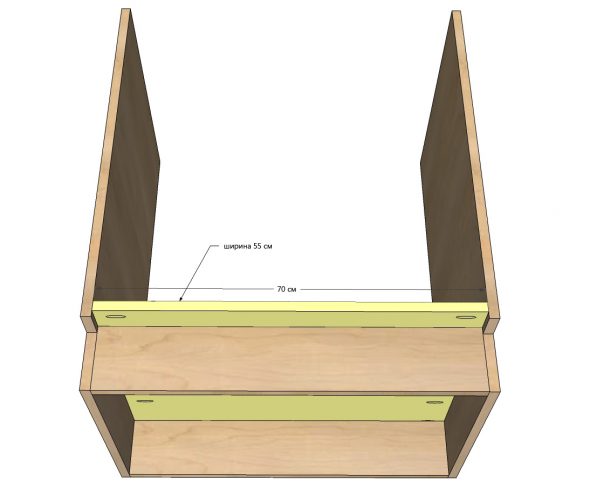

- Frame assembly. Assembly begins with the walls being secured with crossbars.You can use angles or screws for this. After this, the bottom is secured with screws.

- To fix the top of the frame, we use the crossbars in the upper part. We will attach the back wall to one of these cross members. Therefore, it must be quite thin.

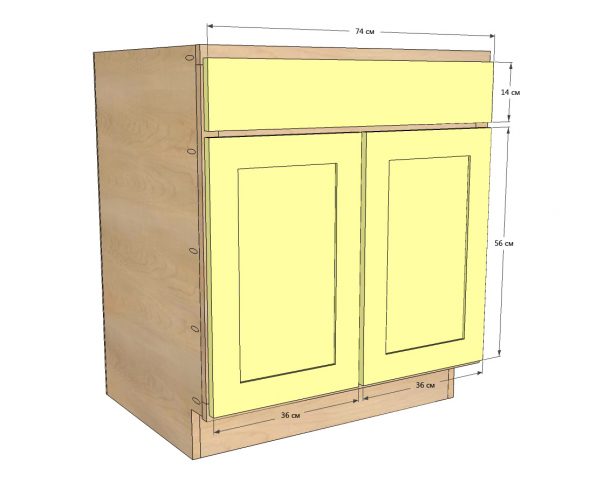

- Fastening the façade. Having placed the door against the body, we mark the place where we will place the hinges. We make holes for them and secure the hinges in the door. After the doors are installed, you need to adjust them. You need to choose loops very carefully and thoughtfully. It depends on them how wide the door can be opened and how long it will function efficiently.

- Exterior finishing. Once the assembly is completed, we will need to somehow decorate our cabinet. It can be covered with film, painted or varnished. Of course, the handles will also need to be screwed on. On the inside of the door it would be useful to add a pocket for small items. To make full use of the internal space, we’ll make a shelf.

Attention! In order for the cabinet to function longer, it must be raised above the floor level; for this, the legs will need to be secured at the bottom.

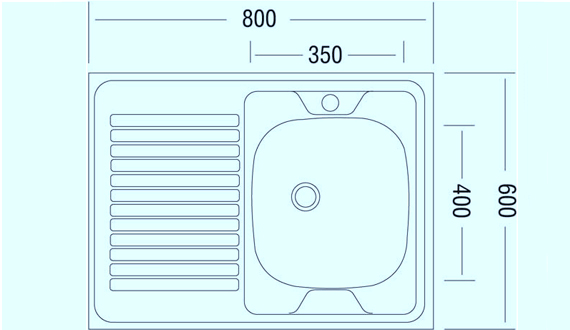

Sink installation

Most likely, this part of the work will be the easiest of what has already been done. A metal sink is installed on top of the cabinet. To ensure maximum rigidity and stability, the sink must be secured. If this point is not observed, then over time the cabinet will certainly fail.

There are two ways to fix the sink:

- Use regular silicone sealant. In this way, we will not only secure the sink to the plane of the cabinet, but also ensure the tightness of the joint.All that is required of us is to evenly distribute the sealant around the perimeter of the upper end of the case. Next, place the sink and press it down. Once the sealant has cured, the entire structure can be installed and connected.

- Use self-tapping screws. They are a more reliable connection. However, this does not exclude the application of sealant. Only this time it is needed not so much for fixation, but rather to ensure the tightness of the joint.

If the cabinet is assembled to fit the dimensions of an already purchased sink, then it will fit into the place provided for it without any problems.

When finished, the entire structure will look something like this.

As you can see, there is nothing complicated in making kitchen furniture yourself. The main thing is to think through everything in advance, prepare tools and materials and, of course, work out the sketch.