Making a sink cabinet from solid wood with your own hands

I really understand those who are not looking for easy ways and make their own furniture. The same cabinet under the sink - you can go and buy it in a store, or you can choose the materials you like, come up with your own design, fit it perfectly into the dimensions of the room, and in general, put your soul into it. So let's not put it off, let's start creating a furniture masterpiece!

The content of the article

Preparing tools and drawing a sink cabinet

I’ll make a very important footnote right away.

Attention! You need to buy a sink BEFORE starting work, not after!

This seems funny, but you can’t even imagine how many would-be masters made mistakes on this and how many cabinets had to be redone after purchasing the sink.

So, first of all, you need to start with measurements:

- free space around the sink;

- its size;

- the height of its location;

- communications, namely: the length of the section with pipes, their diameter and the distance from the wall to their end.

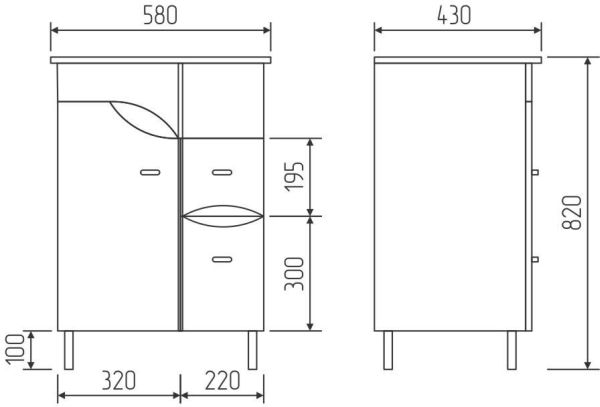

Done? Further. From experience I can say that it is best to start from standard sizes, and then adjust them to your measurements (and your taste, of course):

- height 82 cm;

- depth 43 cm;

- width 58 cm.

The drawing should look something like this:

Now let's prepare all the tools we need to create the cabinet of our dreams. This:

- hammer;

- drill;

- screwdriver;

- jigsaw;

- hacksaw;

- pliers;

- screwdrivers;

- sandpaper;

- something to measure, a tape measure will do;

- paper and pencil;

- grinding machine.

Everything is? If you don’t have something, you can run to the store right now and buy more.

Reference. If you want to use additional materials, you will need the appropriate tools in addition to these.

Ready? Let's begin the sacrament.

Manufacturing and assembly of a cabinet made of solid wood

Any of them consists of a frame base, top, side parts and additional elements - doors, shelves, drawers, canopies, etc. Some of them may have a bottom and legs attached to it. For the frame, beams made of any wood you like are suitable. The top can be anything at all: plastic, plasterboard, glass, wood, etc. Ordinary plywood is suitable for the sides and bottom. Additional elements can be made from any materials you like.

All patterns are first marked on paper, then transferred to the required surface and cut out using a jigsaw.

Important! When making a cabinet with doors, people often forget about the small upper part above them. It does not serve any function other than decorative, but without it you will get an ugly result with a gaping hole. Do not do it this way.

The assembly process begins with the frame base. Afterwards, all parts are sanded and, if necessary, coated with special products to protect them from moisture.

The side walls are attached to the frame (screws and glue are used for this). For additional strength, I highly recommend strengthening the connections with steel or aluminum corners.

Now the top surface. Even if you have checked everything many times before: place the sink in the hole to be 100% sure that all the dimensions are correct. There's no need to attach it yet - we'll do that later, for now we're just making sure everything fits.

Now the bottom. Some people secure it last, but it’s more convenient when the cabinet lies on its side, and in this case, slamming doors and sliding drawers can get in the way. That's why I leave them for last.

Installing a cabinet under the sink with your own hands

So, our beauty is ready, all that remains is to connect it to the sink. It is important that by this stage the entire sink is completely assembled: with taps, handles, water pipes, etc.

The cabinet is placed in the place where it will carry out its long and faithful service. If you have a hanging model, now is the time to attach it to the wall. Remember that you will have to support the weight of not only the cabinet itself, but also the sink, so the fastenings must be as reliable as possible.

Silicone or sealant is applied along the entire edge of the sink, after which it is installed in the hole. There is no need to save money here. If you overdo it, you can always remove the excess. But the “shortage” will only have to be redone.

Reference. There are also models that are attached from the inside of the cabinet using a special fastener system, so that there are no convex elements on the surface. But to install them, it is better to contact a specialist, because the risk of error is too great.

After this, all that remains is to connect the sink to the water supply. If you want to add decorative elements to the cabinet (carved patterns, painting, gilding, etc.), now is the time to start. You can also stick tiles or self-adhesive film on it.

Thus, you will receive a unique piece of furniture in your bathroom or kitchen, created with your own hands, which you can show off to your guests, bequeath to your descendants, or admire in splendid isolation.