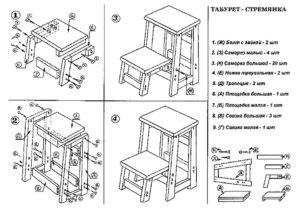

DIY step stool drawings

Making furniture with your own hands is always a responsible and painstaking process that requires skills and increased attention. This solution allows you to significantly save the cost of purchasing things, and also develops multifunctionality in a person. One of the products that you can make yourself is a step stool.

Making furniture with your own hands is always a responsible and painstaking process that requires skills and increased attention. This solution allows you to significantly save the cost of purchasing things, and also develops multifunctionality in a person. One of the products that you can make yourself is a step stool.

The content of the article

How to make a step stool yourself

Initially, in order to begin the work, it is necessary to prepare all the relevant tools, make drawings, decide on the type of material, and also decide what style and appearance the finished product will have.

The work is unique in that it is possible to create several variations of stools: from less complex ones, with the construction of steps, to more advanced ones, with the creation of certain corner joints and mechanisms. The complexity of the job depends on the skills and knowledge of the worker.

Important! The type of material from which the product will be created can also significantly complicate the activity. Thus, natural wood, mainly pine, is the cheapest and easiest to process material. The wood-based base is used to combine the steps and backs of the structure, which allows a person to sit on it more comfortably.Metal structures, in turn, require a welding machine, and are suitable for more experienced workers.

What materials and tools are needed?

The amount of material of the product is determined independently, depending on its type, the size of the structure, as well as the appearance of the product itself and its connections. In the case of making a stool from wood, you will need the following tools:

- saw or hacksaw;

- jigsaw;

- drill;

- Sander;

- glue;

- paint and varnish coatings;

- connecting elements: nails, screws, self-tapping screws;

- hammer;

- chisel.

Making a stool from steel will require more serious and expensive equipment, such as:

- welding machine;

- Bulgarian;

- abrasive tools.

The process of assembling a simple step-stool: step-by-step instructions

The entire manufacturing process must be divided into five stages:

- Creating drawings - making a detailed diagram of the structure and its parts, taking measurements, indicating the results obtained.

- Preliminary – determination and collection of the required amount of material, preparation of tools.

- Initial – production of the supporting structure, seating wall, stairs and connection units.

- Assembling parts - using tools, connect all previously separately prepared elements into a common state, bring the product into its finished position.

- The final step is cleaning the surface, applying protective paint and varnish coatings, and creating a unique decorative design.

Important! Particular attention should be paid to preparatory work and the creation of drawings.After all, the slightest inaccuracy in calculations can lead to improper use of the furniture, and as a result, this can lead to loss of used material, as well as additional costs. If you do not have the skills to make drawings, it would be better to turn to the Internet and find ready-made samples.

How to make a transforming stepladder-stool yourself

A transforming chair is a more advanced version of furniture that allows you to visually change the position of parts of the chair due to moving elements. This allows you to significantly improve the appearance of the product, as well as save some home space by folding the chair when not needed.

In order to create a transforming stool you will need:

- 4 parts of sidewalls: 2 front and 2 rear;

- 3 elements of the back of the chair;

- 2 seat components;

- 3 steps;

- 6 connecting strips.

In addition to the material and tools, you will also need a piano hinge and two sets of guide profiles for steps - 310 mm. They are designed to ensure that the structure is movable and allows you to comfortably change the given position.

After preparing the drawing and processing the elements, the back and sides of the chair are attached to the base using self-tapping screws. The seat and steps are fastened in grooves previously hollowed out with a chisel. The joints also need to be lubricated with glue, strengthening the elements and making the gaps between them minimal.

The main parts - the steps and the pull-out stool - must be connected using a piano loop of the required size.Also, after completing the assembly of the transformable stool, you can give a unique appearance to the back of the chair and the seat by painting them in different colors, which can highlight each other and give a more elegant appearance to your achievement.

Adviсe! To make the chair legs more stable, it is necessary to cut all sides, with an inclination of 10 degrees. Also, gluing of parts must be carried out after a thorough visual inspection. If there are defects, this will help to correct the defect more easily and quickly. Another important tip is to mill the planes and connecting grooves. Mechanical processing will prevent chipping and damage to sharp edges.

Making a step stool with your own hands is quite easy, the main thing is to treat the work with understanding and care. Making furniture with your own hands is always profitable and beautiful, and can be celebrated as a personal achievement or used as an unusual and pleasant gift for others.