DIY metal chairs

Wooden furniture has always been popular. But there are cases when its use is inappropriate. The metal is strong and durable, and the furniture made is stylish and elegant. Working with this material is not very difficult. You just need to have experience with welding and the required materials.

Wooden furniture has always been popular. But there are cases when its use is inappropriate. The metal is strong and durable, and the furniture made is stylish and elegant. Working with this material is not very difficult. You just need to have experience with welding and the required materials.

The content of the article

How to make metal chairs yourself

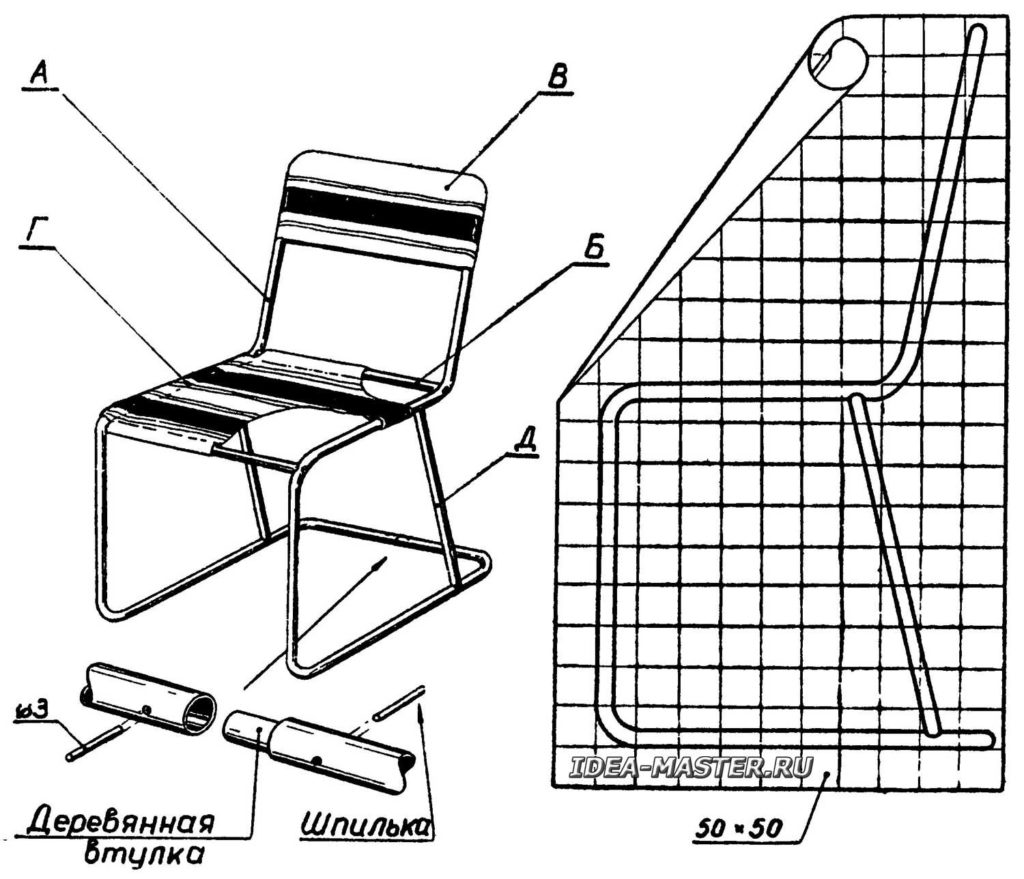

To assemble metal chairs you will need a pipe bender. You can assemble it yourself. Why in the workshop fix two bars on the workbench. Between them you need to leave a gap where the metal pipe is inserted. Fill it with sand, insert wooden plugs at the ends and then you can give the blanks the required shape.

Attention! Before starting work, you need to draw up a detailed drawing. Draw the required chair model. Indicate the dimensions of all furniture elements. According to the drawing, make a life-size stencil from a plywood sheet, against which you can later check the accuracy of the blanks made.

Which metal to choose

Metal is the most durable material for making furniture. When properly processed, it is not afraid of either moisture or sunlight. There are 3 types of metals suitable for making chairs:

- Aluminum. This is a lightweight material and is used to make small items. The main advantage: resistance to corrosion, so the furniture can be used in high humidity.But aluminum is quite fragile and cannot withstand significant loads.

- Steel. Large-sized furniture is made from this material, which must be frequently rearranged while maintaining strength. The metal is subject to corrosion, but this problem can be solved by priming and painting.

- Cast iron. This is a strong and durable metal. The disadvantages include its heaviness, which is why chairs for the garden are most often made from it, which do not need to be rearranged often. Subject to corrosion - the surface must be coated with an anti-corrosion compound. It is very difficult to make cast iron chairs yourself.

Required tools and materials

To work you will need:

- Metal profile with a cross section of 19-25 mm.

- Studs and bushings.

- Electric drill with metal drill.

- Plywood sheet for stencil.

- Screws.

- Facing material.

- Pipe bender

- Scissors.

- Roulette, marker.

- Varnish, paint.

- Sandpaper.

- Sewing machine.

Metal chairs: step by step

Today in interiors you usually find high chairs on an iron frame, which are called bar chairs. Products can also be made with a small back and armrests.

Attention! To make this furniture you will need steel tubes with a cross section of about 22-27 mm. Also a welding machine, metal scissors, tape measure and pencil, grinder or sandpaper. To cover the chair you will need paint or varnish.

The work is carried out in the following order:

- Make a layout from a plywood sheet that you can use as a guide.

- Cut pieces from steel pipes for the seat frame.

- Weld the cut pieces to form the desired shape.

- Cut small pieces of steel to fit into the seat frame. Weld all the elements.

- Sand the resulting product so that it is smooth.

The chair seat is ready. Next, they begin to make the legs. To do this, you need to cut 4 parts of the required size from a square profile with a cross-section of 4 cm. The height of the product must be determined independently, taking into account the needs. The seat must be approximately 45 cm below the table level.

Do not weld the prepared legs tightly to the body. Assess whether the chair is level, only then complete the welding. This chair needs a footrest. Mark the area where the backing will be located. The optimal distance is approximately 32-37 cm from the seat. Cut pieces of the required size from the steel pipe, install between the legs, and secure with a welding machine.

Metal chairs fit perfectly into the interior of any room and can be used as garden furniture. Metal only seems “heavy”, but designers prove the opposite with their examples of work. And if this is not a single piece of furniture, but several, made in a common style and located in the same composition, then it will truly decorate any room.