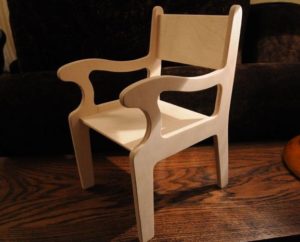

DIY plywood chair

As many may know, there are many types of chairs. They differ from each other both in shape, in size, and in the original material. In this article we will try to consider in detail one of the design options, learn how to make a chair from plywood with your own hands and what features should be taken into account during the work process.

The content of the article

Features of plywood chairs

Before you move on to manufacturing, you need to go through a number of points that will allow you to work more productively. So, you must first decide on the purpose of the future structure. So, it has a number of models, depending on the place where the chair will be suitable. This can be either a children's room or a kitchen room. After this, it is advisable to objectively assess your capabilities.

If you are just starting this type of activity, then it is not recommended to immediately proceed to the advanced level. There are a lot of simple samples that everyone can implement, thereby gaining some experience. Size is important. It depends on the personal preferences of the user and the interior space. The next thing you should pay attention to is the design. It is also determined in advance.

Necessary materials

To complete the job, of course, you will need the following items:

Sander.

Sander.- Ruler and pencil.

- Electric jigsaw.

- Construction adhesive.

- Self-tapping screws.

- Hammer.

- Cardboard measuring 600 by 900.

- Textile.

- Special jig for assembly.

- Foam rubber (70 centimeters thick).

- Bolts.

- Sheet of plywood (600 by 900, 2 millimeters).

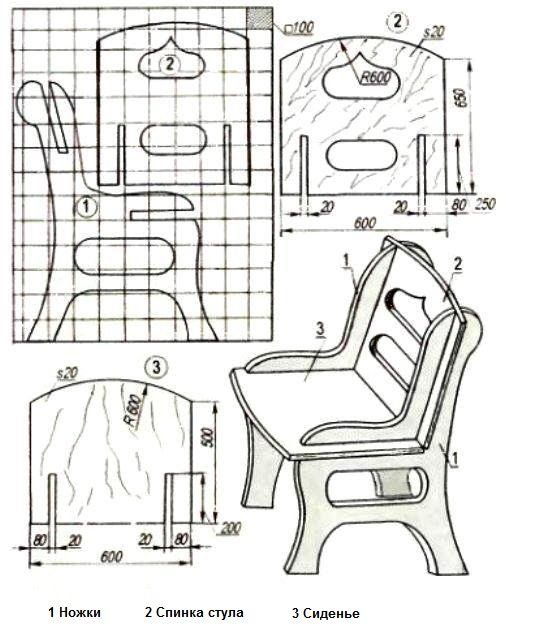

Project and drawings

Of course, the presented aspect is selected individually. It all depends on your desires, and most often on the user’s growth. Thus, for people with parameters up to 130 centimeters, a height of up to 30 cm will be required. For the interval from 130 to 145 cm - 34, respectively. Up to 165 - 42, for people from 165 to 175 cm - 46. The height of the chair for a person with a height above 175 cm should be 48 cm.

REFERENCE! It is advisable to use such standard sizes in the work of beginners who are not particularly versed in the technique of creating a sample. If you have experience, you can experiment at this stage and pay attention to new forms of the product.

Manufacturing algorithm

And so, when you are armed with the necessary tools, and have a goal in mind, then you can begin the most important and basic process. By following the instructions in the given sequence, you will get amazing results:

To begin with, it is advisable to transfer the pre-made template onto cardboard using a pencil and ruler. Then you can start cutting out each part. When everything is ready, you should move the samples onto the plywood.

To begin with, it is advisable to transfer the pre-made template onto cardboard using a pencil and ruler. Then you can start cutting out each part. When everything is ready, you should move the samples onto the plywood.- Next, the elements are cut out using a jigsaw. The main thing is to do everything carefully, along the contour.

- Then you can polish the products using a special machine. If this is not available, it is recommended to use sandpaper.

- After this, you should create holes. They are needed for hinges.To give the most strength, you can use glue on the sleeves.

- Similar recesses will be required for the tenons.

- After the manipulations have been completed, it is possible to begin assembling all components into a single system.

ATTENTION! This is done on the basis of the drawing. The seat is fixed and the foam is cut out to give a soft position. When processing fabric, it is advisable to use a stapler.

Decoration option

Of course, the whole process does not end there. In the modern world, there are several options for decorating your invention. The most common is the use of special varnish. Thanks to it, the surface is guaranteed to last for a long time. Thus, the building will look more attractive. Another way is to mark the ornament. The main advantage is the opportunity to put your unlimited imagination into practice. Anyone can easily add personality to a seemingly ordinary device. Simple fabric can also become decoration. Using this method it is easy to add addition to the interior.

Of course, the whole process does not end there. In the modern world, there are several options for decorating your invention. The most common is the use of special varnish. Thanks to it, the surface is guaranteed to last for a long time. Thus, the building will look more attractive. Another way is to mark the ornament. The main advantage is the opportunity to put your unlimited imagination into practice. Anyone can easily add personality to a seemingly ordinary device. Simple fabric can also become decoration. Using this method it is easy to add addition to the interior.

Useful tips

Here are some tips that emphasize simplifying actions:

- The algorithm described above emphasizes the use of foam rubber. However, this action is not mandatory. This is explained by the fact that the seat can be hard. This technique is perfect for home needs.

- As for the use of plywood as the main material, it is important to maintain its thickness. The main thing is that it is reliable.

- After preparing the parts, you should check them for strength.