DIY tennis table

Owners of spacious premises or country houses try to add as much decorative furniture to the interior as possible. Golf lovers will create a clearing with a beautiful lawn and holes in their backyard. The football player will install the goal. A table tennis fan will place a decorative table in the entertainment room or in the courtyard of the cottage. Table tennis is a pretty good option in both cases. By playing this sport derived from tennis, you do not get too tired and develop your reaction. It will help pass the time and have fun for both children and adults.

But a tennis table costs a decent price considering its simplicity in design. Prices for such a table range from $25-$90. Of course, if you have skillful hands and simple technical devices, the best option would be to assemble a tennis table with your own hands. How to do this and what is needed for this is worth considering in more detail.

The content of the article

Tennis table dimensions

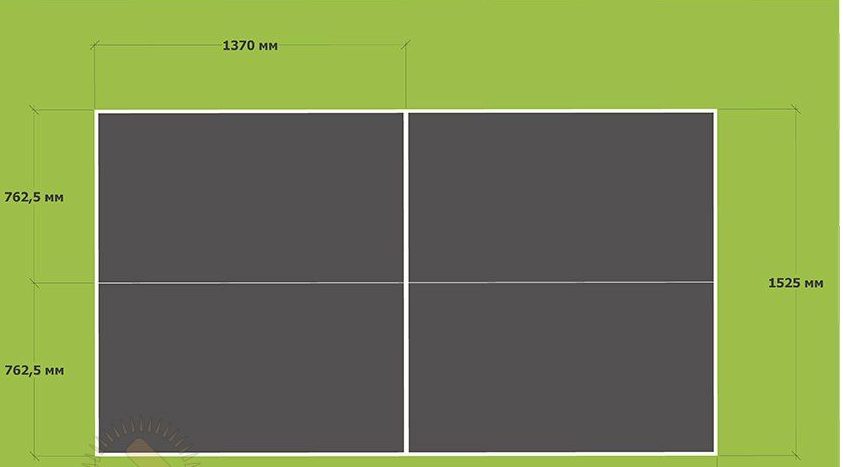

To make the game convenient for adults and children, it is worthwhile to correctly calculate the dimensions. In fact, there are no exact dimensions for this product. Different manufacturers make different tables, but their dimensions are difficult to discern from the outside. They are made comfortable for average height people. The best options would be the following sizes:

- Height - 0.95m-1m.

- Length (both sides) - 1.9m-2.05m.

- Width - 1-1.3 meters.

If you can imagine this table, make sure that its dimensions are really comfortable. The height of the structure will be optimal for all players. And the platform (on one side) 1x1 in meters is accessible to the arm span of adults and children. Having learned about the dimensions of the product, let’s move on to detailed instructions.

How to make a tennis table with your own hands

As already mentioned, there is nothing difficult in making a tennis table. First of all, you will need a drawing. You can depict it yourself or using a photo from the Internet.

Blueprints

Without much trouble, draw the dimensions of the tabletop (remember, it should deviate from the supporting structure by at least 20 cm so that the players do not touch it with their feet). Next, draw a supporting structure consisting of 4 legs interconnected by additional components.

Tools

After creating the drawing, let's prepare the necessary tools:

1. Electric saw (you can take a regular hacksaw).

2. Meter or tape measure.

3. Level (for balancing. In a tennis table this is very important).

Now, the tools and drawing are prepared, it’s time to start choosing materials for our treasured table.

Countertop material

The main part of the tennis table is representative. It plays a key role not only in design, but also in the convenience and comfort of the game. There are many options for choosing material for the countertop. We'll take just a few of them and look at the pros and cons of each.

- Styrofoam. Plastic foam has some advantages for this role, but has one big drawback - a low stiffness coefficient. Even if you take the densest brands of this material, you will not see the natural bounce of a tennis ball; it will fade by ~ 15–30% (depending on the type of PP). Otherwise, a very good option: minimal cost, easy processing.

Plywood. Plywood is a multi-layer wood panel consisting of veneers of different types of wood. Plywood is also a good option for creating a countertop. Unlike foam, plywood pushes the ball away with full force. But if you take thin subspecies of plywood, the tabletop will delaminate over time or during the first application of paint. If you can find plywood boards, then this option is quite suitable!

Plywood. Plywood is a multi-layer wood panel consisting of veneers of different types of wood. Plywood is also a good option for creating a countertop. Unlike foam, plywood pushes the ball away with full force. But if you take thin subspecies of plywood, the tabletop will delaminate over time or during the first application of paint. If you can find plywood boards, then this option is quite suitable!- Chipboard. Most tennis tables are made from particleboard (chipboard). This material has all the best qualities and is more suitable for this role than others. A dense, durable and cheap panel is perfect for making a tabletop, but in order not to bother with processing, take the highest quality varieties. Their surface will be smooth, which will be a big plus. All that remains is to varnish or paint the table, but more on that later.

We will use high-quality chipboard as the material. Let's move on to the base.

Base

The base consists of 4 beam legs (in the best case, 6) connected to each other by additional boards so that the legs do not diverge due to the weight of the tabletop. We will take the option with 4 legs. It is much more convenient, and slightly cheaper.

The main stage of work

The time has come to assemble a full-fledged table from all the blanks according to the drawings. Let's start from the foundation.

To begin, saw off 4 identical legs, one meter long, from the bars. You can measure them using a prepared tape measure. Next, we will make connections for the legs.

To calculate how much length is needed, subtract the thickness of both bars from two meters and another 20-30 cm. In width - the same thing with only one meter, but there is no need to retreat, there is nothing stopping the players there. Having connected all four legs from above, it is recommended to strengthen the base in the same way, with bars in the middle of the legs. Having done everything exactly as planned, you will get a strong and comfortable base. Making a tabletop will not be difficult. Measure 1 square meter from the solid panel. m. and saw it off.

The second side is made in the same way, since they must be absolutely identical for both sides. Having prepared the base of the tabletop, you can begin its secondary processing - varnishing and painting. Some types of chipboard have already been treated for longer service life and do not require additional chemical treatment. devices. If your panel is of poorer quality, then you will have to treat the countertop with stain or varnish for durability and a smooth surface. Be sure to carry out the treatment outdoors to avoid headaches and poisoning. Let both parts of the countertop dry for a couple of days. As a result, you get two identical panels with an area of one meter square. If you wish, you can paint the table in your favorite color.

Assembly of the structure

Now that the two main parts of the table are ready, it’s time to assemble them into one whole. You can do this in three ways:

1. Connect with nails.

2. Using self-tapping screws.

3. Do not connect.

Manufacturers prefer not to screw/drive the tabletop to the base, as there is a possibility of misfires when playing. The weight of the chipboard panel will perfectly support the table without additional fasteners.Another plus is ease of transportation - the tabletops are easier to carry separately and in a horizontal position. All that remains is to install the grid, or a homemade one.

Expert advice

If you want to make the table more durable, just in case, add two additional legs in the middle to your drawing. Thus, the table can easily withstand even strong accidental collisions!

So, we hope you have understood as much as possible how to make a table with your own hands. Whether to make it as a decorative element or for sports activities is up to you. The main thing is that we were convinced of the budget and originality of such a table.