DIY solid wood table

Furniture made from solid wood belongs to the elite class. It is good quality and durable. Wood in the interior gives the living space exclusivity and special expensive comfort. The price of such furniture is high. Nevertheless, the demand for it is constantly growing.

Furniture made from solid wood belongs to the elite class. It is good quality and durable. Wood in the interior gives the living space exclusivity and special expensive comfort. The price of such furniture is high. Nevertheless, the demand for it is constantly growing.

The content of the article

Why do you need to make furniture yourself?

The reasons that motivate you to start making furniture are different.

The high price is often a deterrent. But if you make it yourself, a new piece of furniture will cost less than a similar item in a store.

The desire to dilute a boring interior with an exclusive piece of furniture. A product made with your own hands has special value. Sizes, shape, decorative elements will correspond to your consumer and aesthetic needs.

How to make a table from solid wood

Without woodworking skills, deciding to make a piece of furniture yourself is quite difficult. You can start with a simple and necessary item - a table.

At the initial stage of work, design decisions are made. The design of the table is related to the functional purpose and characteristics of the room.

How well the table will look in the room depends on its characteristics and functions:

- From the dimensions of the table. Large-sized is good in a large living room or dining room when you plan to receive a large number of guests.In a small room, a bulky table is inappropriate. If you need to solve two mutually exclusive problems - to obtain a structure with a large capacity without taking up additional space, the option of a sliding or folding table is suitable. The optimal height of the product is 70-75 cm.

- Forms. It is chosen based on one’s own taste. The main types of countertops are rectangle, circle, oval. A triangular table can add special expressiveness to the interior. The Internet, on whose pages a huge number of different models are posted, will help you suggest an interesting solution.

- Wood species. Wood is selected for its consumer and decorative properties. The easiest species to process are spruce, pine, fir, and aspen. Hard varieties - beech, oak, acacia, birch. The complexity of processing is compensated by resistance to deformation and beautiful wood texture. Many types of wood are prone to rotting. The deficiency is eliminated using antiseptic treatment.

- Style and matching the interior.

Materials and tools

It is advisable to prepare the necessary materials and tools in advance.

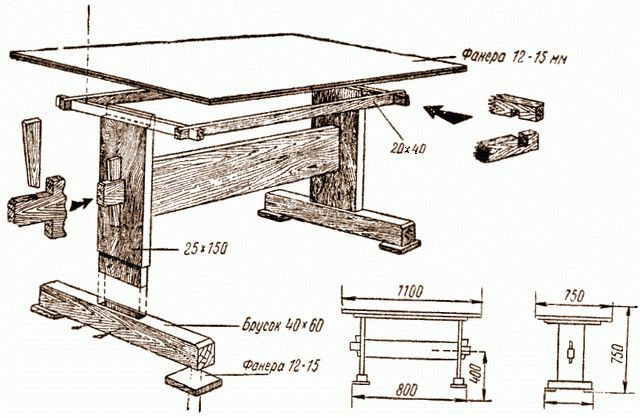

It is easier for novice craftsmen to start making a table with a rectangular table top and 4 square legs. The set and quantity of materials depends on the design of the table:

- Tabletop boards with a thickness of 40 mm or more.

- A beam with a cross section of 40x40 mm, providing the structure with stability and strength.

- Designs for table legs. There are many options for making legs - wooden balusters, metal profiles, solid wood supports.

- Furniture dowels or confirmants for fastening individual parts of the structure to each other.

- Antiseptic.Special impregnations improve the appearance of products, protect against fungal infections, and eliminate defects.

- Stain, varnish or paint for covering the surface of wooden structures. Finishing work will give the products a finished look and protect them from influences.

You will also need tools for work: rulers, squares, and levels are intended for measuring structural elements.

To work directly with wood you need: a saw, a jointer, a sanding device, and sandpaper.

To connect the individual parts you will need: clamps, screwdrivers, screwdriver, drill, mallet.

Attention ! You will also need hand and eye protection - glasses, gloves. A pencil is needed to mark the required positions.

Measurements and drawings

Carpentry work begins with a drawing of the room plan with the arrangement of furniture. It is necessary to determine how well the table will fit into the living space, taking into account ergonomic requirements. To draw up a drawing, measurements of the room and all elements of the objective content of the environment are taken. Furniture items are placed on the plan and the quality of the resulting composition is assessed. All cabinet doors should open freely, the passage should remain clear, and the space around the table should be comfortable.

After choosing the dimensions and shape of the table, select or order a drawing of the product. Without carpentry skills, it is difficult to carry out drawing work, so it is necessary to take into account the subtleties of making connecting nodes.

Reference! You can also use a special computer program. The result obtained is printed on paper for clarity during the work process.

DIY solid wood table: step by step

After carefully studying the drawing, you can begin to work.

Step 1. Surface treatment. If the tabletop is not made from a solid cut, you need to carefully process all parts. The boards are adjusted to the specified dimensions and processed with a grinding machine. Particular attention should be paid to the edges, since the tightness of the contact of the tabletop elements to each other depends on the quality of their processing. To avoid deformations, the boards are laid in a pattern alternately in different directions.

Step 2. Connecting tabletop parts. The parts are connected with dowels and glue. To install dowels on the edges of the boards, mark the connecting nodes with a pencil in increments of 100-150 mm. The edges and holes for the dowels are coated with glue. Any adhesive that appears on the surface of the countertop is removed with sandpaper. The surface is carefully polished. The surface of the tabletop acquires a textured appearance after treatment with a metal sponge.

Step 3. Making the base. Using screws and glue, the balusters are connected to the cross bars necessary for stability. The screws are screwed into pre-drilled holes on the inside of the crossbars.

Step 4. Table assembly. The table top and base are secured with screws or self-tapping screws. Glue is often replaced with metal corners.

Step 5. The surfaces of the assembled product are coated with varnish or paint.

A solid wood table can be made even by a person who is not involved in furniture assembly. The main thing is to follow the instructions and strictly follow all recommendations.