DIY plywood table

Homemade furniture is a cheap and original solution that can make the interior of your home more attractive and comfortable. Of course, to design something truly complex, you need the appropriate skills. However, a plywood table is a fairly simple piece of furniture that does not require much time and effort. Having understood the issue, even a novice master will be able to create it.

Homemade furniture is a cheap and original solution that can make the interior of your home more attractive and comfortable. Of course, to design something truly complex, you need the appropriate skills. However, a plywood table is a fairly simple piece of furniture that does not require much time and effort. Having understood the issue, even a novice master will be able to create it.

We'll tell you how to make a table out of plywood with your own hands.

The content of the article

Materials and tools for work

An important stage of work is the preparation stage. Stock up on all the necessary tools and materials, make sure you have a good understanding of the process at all stages.

How to choose plywood for a table

The main component is, of course, plywood. To create a table, sheets consisting of at least 5 layers of veneer are suitable. The thickness of such panels varies from 16 to 30 mm. The length and width of the plywood are not critical; the choice depends on the size of the tabletop you want to achieve as a result.

Important! The quality of a plywood sheet can be judged by examining its surface.Samples suitable for such work are smooth, have a uniform color, and do not contain knots, cracks or other defects.

What tools and materials to prepare

For the manufacture of

As you work, you will need the following.

- A jigsaw or circular saw for cutting plywood.

- Furniture glue.

- Thick cardboard or other similar material for creating life-size templates.

- Pencil and long ruler.

- Fastening elements - bolts, furniture corners or wood screws.

For processing

A separate line is worth highlighting the materials needed at the stage of final processing of table surfaces. This is usually a sandpaper or grinder for initial processing. And wax, varnish or paint to finalize the piece of furniture.

Important! The texture of natural wood, which is obtained by treating surfaces with transparent varnish, will fit well into interiors in loft, minimalism, and country styles.

However, a strict classic room, as well as ultra-modern high-tech, harmonize better with painted products.

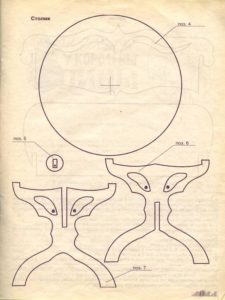

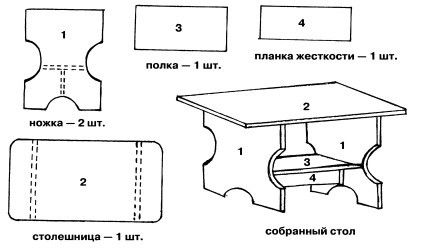

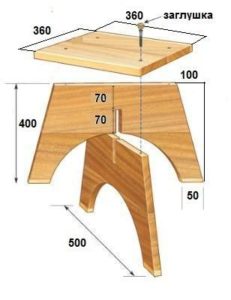

Table drawing

Creating an accurate drawing is the next part of the preparation process. Draw out the tabletop and legs with dimensions on paper. The more complex the shape of the product that is planned to be assembled, the more detailed the diagram should be.

After completing the drawings, transfer the elements depicted on it in real sizes onto cardboard. Cut out the resulting fragments - they will serve as templates for working with plywood.

How to make a table from plywood

After the tools, materials, drawing, and templates are prepared, it’s time to begin the process of creating the table. To do this, follow the instructions.

Part marking

Take a cardboard template, secure it to a plywood board with masking tape, and trace it with a pencil. Thus, it is necessary to outline all the components of the table, starting with the tabletop and ending with the legs or side stands that replace them.

Cutting out parts

To do this, use a jigsaw or circular saw. It is easier to cut a triangular or square shape than a curved one. But the latter can also be dealt with using patterns.

Surface treatment

We are talking about grinding elements using sandpaper or another grinding tool.

Important! The joints are subjected to the most careful processing. They must be absolutely smooth so that the parts fit together as well as possible.

Connection of product components

Mark with a pencil the location of the fasteners. Drill holes in these places using a drill with a diameter slightly smaller than the screws. Then process the top of the resulting holes with a drill with a large diameter - this process is called countersinking.

Then connect all the components. Make sure that the joints are tight - then the table will last a long time. Place caps on the heads of the self-tapping screws.

Varnish or paint coating

Varnish will allow you to show off the wood texture, while paint will add a little color to the interior. Both options have their own advantages.

Important! An interesting solution is to paint the legs and tabletop in different shades.

Useful tips

- The most important thing when designing your own table is to make it fairly stable. To do this, you can additionally connect the vertical legs with horizontal elements, even creating an entire frame.

- Sometimes it is recommended to try to glue together, respecting the proportions, a small model of a future piece of furniture made of paper or cardboard. This is usually enough to understand whether the invented model will hold up or not. You also need to somehow strengthen its supporting elements.

Creating a table with your own hands is somewhat reminiscent of playing with a construction set in childhood. Only the result is significantly more useful and durable.