DIY chipboard table

When faced with choosing furniture for the kitchen and living room, many craftsmen do not run to the store, but decide to make a table from chipboard according to their own tastes. This method is both faster and relatively cheaper. Even with minimal DIY skills, you can make a homemade table. In addition to the obvious advantages, the table will stand out due to its exclusivity. Everything you need for work can be found in the house.

When faced with choosing furniture for the kitchen and living room, many craftsmen do not run to the store, but decide to make a table from chipboard according to their own tastes. This method is both faster and relatively cheaper. Even with minimal DIY skills, you can make a homemade table. In addition to the obvious advantages, the table will stand out due to its exclusivity. Everything you need for work can be found in the house.

The process of making furniture with your own hands is filled with pleasant bonuses. The craftsman chooses the design himself, takes into account the layout of the apartment - and there is no need to go to furniture stores with a tape measure in hand! A person fully reveals his own creative potential, reaping a lot of benefits in terms of costs and acquiring new skills. Let's consider the process of making two tables: a large kitchen table and a small coffee table for the living room.

The content of the article

How to make a kitchen table from chipboard with your own hands

The kitchen table is the most used of all the furniture in the house. It is at this place that people eat and spend most of their time talking. The table should be visually attractive and durable. Chipboard is an ideal material for kitchen furniture, as its advantages lie in practicality and long service life.In addition, it is a lightweight material that is easy to process and create a full-fledged kitchen table.

The kitchen table is the most used of all the furniture in the house. It is at this place that people eat and spend most of their time talking. The table should be visually attractive and durable. Chipboard is an ideal material for kitchen furniture, as its advantages lie in practicality and long service life.In addition, it is a lightweight material that is easy to process and create a full-fledged kitchen table.

Table drawing

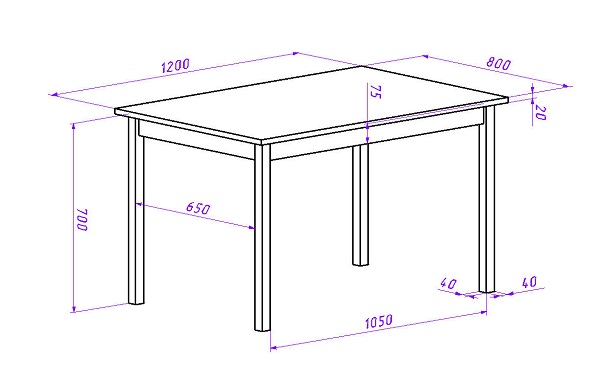

You can make a drawing of the table yourself - absolutely according to your own preferences, or use the template we offer.

IMPORTANT! It is imperative to take into account the dimensions for the blanks, both in an independent diagram and using ready-made templates. Otherwise, an opportunity will arise - the finished table will be smaller or larger than the required size.

Let's consider the simplest table in design with a wide but small tabletop, four legs and reinforcing supports.

Necessary tools and supplies

The first step is preparing the necessary tools. For fruitful work you will need:

- drill or screwdriver - it’s better to take small models so that the mounting points look nice;

- circular saw, router and jigsaw;

- auxiliary tools: level, square, tape measure, drills, countersinks;

- set of hex keys;

- hand saw for wood;

- conductor.

IMPORTANT! The main work on cutting and preparing workpieces is best done outdoors (for example, in a garage). This way the noise and pollution levels will not affect the house.

To assemble a chipboard dining table you will need the following parts:

- 4 side stands (74x46 cm);

- tabletop (95x56 cm);

- support frame for the tabletop (2 pcs. 3x5 cm: length 72 cm, 2 pcs. 30 cm);

- 10 furniture corners;

- bottom spacer (4x3.5 cm: length 74 cm).

All blanks are cut from chipboard sheets. In addition, you will need self-tapping screws to secure all the parts.

ADVICE! Before you start cutting out the parts, it is recommended to draw them out on a sheet of chipboard with a simple pencil. You will get a kind of wooden pattern.

We manufacture components

The tabletop is always cut out first - you need to round the corners, giving it the desired shape using a jigsaw. The second is to assemble the frame for the strength of the tabletop - 4 pieces are joined together, secured with corners or self-tapping screws. The support frame must be positioned exactly in the middle of the table top.

The third will be the side racks:

draw horizontal lines from the edges on a suitable slab;

draw horizontal lines from the edges on a suitable slab;- make marks in the shape of ovals;

- cut out the drawn ovals;

- cut the center along the drawn strip.

The second rack is made in the same way.

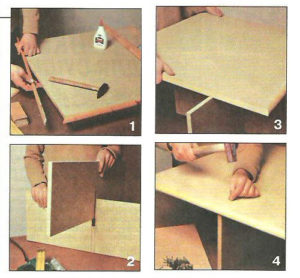

Assembling the table

Place all parts on a level surface. Assembly also begins from the countertop. You need to retreat 11 cm, drawing horizontal stripes - you will get a square right in the center of the slab. This is where the frame will be located - secure it. Next, you should make marks for the side posts, attaching them in the same way in the center, but to the thrust frame.

After assembly, all that remains is to insert the lower thrust beam to space the legs and secure it using corners. For strengthening, the side racks are screwed once again with self-tapping screws - from the outside of the tabletop.

After assembly, all that remains is to insert the lower thrust beam to space the legs and secure it using corners. For strengthening, the side racks are screwed once again with self-tapping screws - from the outside of the tabletop.

It is important to remember that before assembly, all parts must be cleaned and processed - for example, with putty and varnish. Or you can cover it with a special film.

How to make a coffee table from chipboard

A coffee table is twice as easy to assemble because it is compact and doesn't require much work. Such a table is usually low - at the level of the sofa, or even lower. The simplest scheme is to place a round tabletop on 2 parallel bars. The most convenient, affordable and fast. But to make something more serious, you will need similar tools and components.

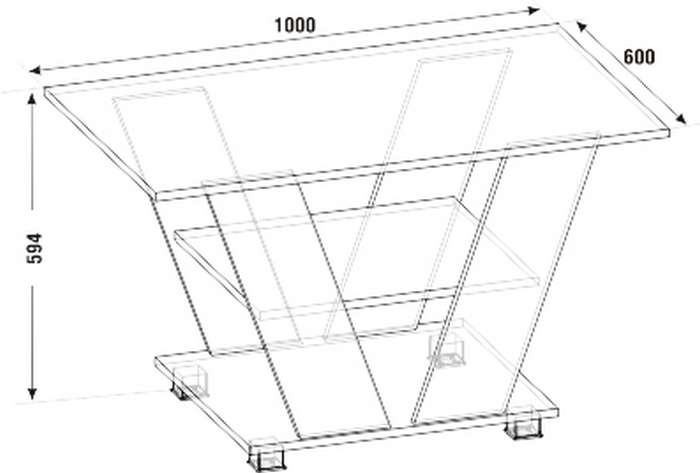

Making a drawing of the table

You should make your own measurements and calculations or use a ready-made diagram by simply copying it. The main thing to remember is that even they can be changed to suit you. Be sure to consider the dimensions.

Preparing the ingredients

The coffee table will consist of the following parts:

- tabletop (75 cm by 70 cm);

- 4 planks (46 cm by 10 cm);

- 2 flat shelves (70 cm by 50 cm);

- 4 legs or wheels;

- additionally: firmware, self-tapping screws, plastic corners and material for processing.

Depending on your wishes, there may be just legs or wheels. Or you can combine them by cutting out holes for wheels in the legs - this way the table will be mobile and easy to move.

Table assembly

The tabletop and lower shelves must be cut out yourself. Before work, be sure to sand the sheet, then make pencil markings and cut out the parts.

All end elements should be glued with a decorative edge, after which you can begin assembling the table top, shelves and side strips using corners and self-tapping screws. The next step is attaching the bottom. Further equipment with legs or wheels.

IMPORTANT! It is recommended to attach the supports at least 1.5 cm from the edge.

The table is ready, all that remains is to decorate it and check its strength.

The final stage is decoration

The only thing left to do is cover the prepared surface with transparent varnish or decorative film. Before painting, you should also treat the table with impregnation to neutralize the glue. In addition, the table will become moisture resistant. It is better to apply the varnish in two layers. You can also attach an LED strip inside the table as a decoration.

The only thing left to do is cover the prepared surface with transparent varnish or decorative film. Before painting, you should also treat the table with impregnation to neutralize the glue. In addition, the table will become moisture resistant. It is better to apply the varnish in two layers. You can also attach an LED strip inside the table as a decoration.

By spending some free time and a little money, you can get a comfortable and unique table.The main thing is not to be afraid of your own mistakes, but to turn failures into the unique charm of furniture.