DIY circular saw table

A table with special holes is a convenient option for securing a hand-held circular saw of a certain diameter.

A table with special holes is a convenient option for securing a hand-held circular saw of a certain diameter.

The design has a number of obvious advantages. She makes it possible to perform a much larger volume of work with minimal effort and with excellent accuracy.

Stationary arrangement of a complex tool allows you to ensure a high level of safety for personnel and increase the service life of the device.

A homemade table for a hand-held circular saw is beneficial for use in cases where the volume of work is not so large and there is no point in purchasing special equipment. The cost of the device, often made from scrap materials, is much lower than an industrial product.

We'll tell you how to make the desired table with your own hands.

The content of the article

What should a table for a circular saw look like?

The complexity and danger of the work to be performed on a homemade table for a circular saw involves, first of all, concern for the strength of the device and its resistance to multidirectional loads.

IMPORTANT! During operation, a circular saw causes significant vibrations and its power is quite large. Therefore, sustainability issues should be taken into account first when designing.

Other important characteristics of the device include the following parameters.

- Smooth working surface, presence of fences.

- Availability of controls, especially the ability to quickly turn off power.

- Availability of all devices necessary for high-quality and productive work. Namely: parallel stop, square, carriage, lighting devices, for cleaning the workplace from chips and dust.

The main task for a sawing table is to perform high-quality transverse and longitudinal cuts of materials from different types of wood: hard (oak, ash), soft (linden, pine).

In this case, the ability to work highly productively is important, especially in adapted conditions - on a construction site, in a garage or in a shed.

Materials and tools for manufacturing

To make the frame, a metal corner or a profile pipe made of carbon steel is usually used. Timber made from durable wood, especially oak, ash, and maple, is ideal. Good stability on different surfaces and resistance to stress are also ensured by high-quality glued materials.

Requirements for the working surface include resistance to bending, a flat, smooth surface, and sufficient slipperiness. That's why often it is made of chipboard, MDF or metal sheet.

Fasteners for both the saw and accessories are preferable to stainless steel. Power supply devices must be in working order.

How to make a table for a circular saw

Having prepared everything you need, you can start working.

Table details, their dimensions, drawings

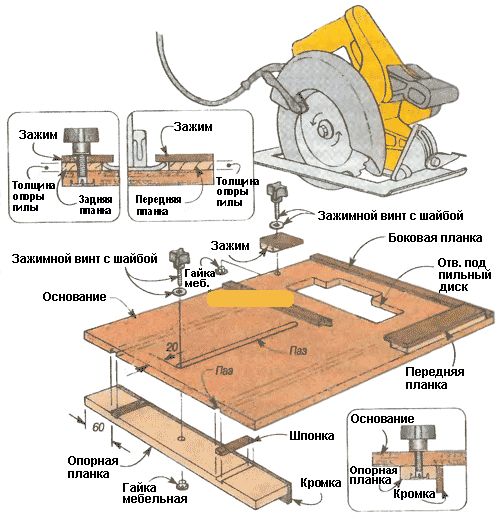

A hand-held circular saw installed in a table must be securely and firmly attached. Respectively, A table top made of non-bending material is required. If it is a wooden board, its thickness should be at least 20 mm for low-power devices.

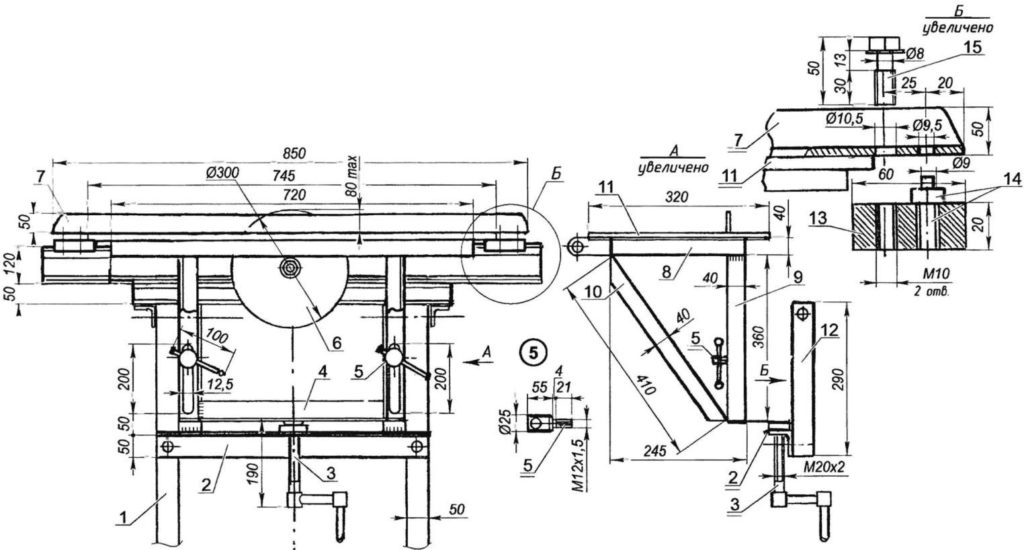

The length and width of the structure are selected taking into account the operating characteristics and parameters of the saw. For a device with a power of up to 1.2 kW, 1000x600 mm is usually sufficient.

The height of the structure should be comfortable for work. It is adjusted to the specific performer, it is approximately 650–650 mm.

The hole for the saw is located offset to the right side in width and in the center along the length. To install and fasten the rip fence and square, appropriate grooves should be made in the table top.

Assembly

First, the base of the product is made.

Important! If a metal angle or profile pipe is used, reliable and durable welding should be ensured.

After completing welding work, the product should be cleaned and painted. The wooden structure is secured with bolts, self-tapping screws, and other devices.

The tabletop is usually attached to the base with bolts, the heads of which are recessed relative to the level of the working surface.

Useful tips

- It is recommended to ensure good lighting for your desktop.

- The lamps are installed on the right front, at a sufficient height.

- The table is installed on a flat surface. You should take care of its preparation in advance.