DIY 3D printer table

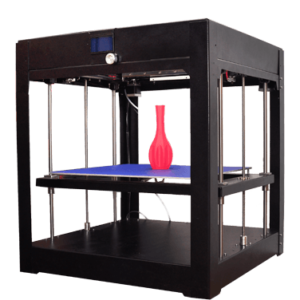

Relatively recently, a new invention has appeared in the field of printing, which makes it possible to create three-dimensional figures of varying complexity and configuration. This significant discovery made a huge contribution to the development of all spheres of human activity. Printing three-dimensional parts from polymer materials solved the problem in the manufacture of complex structural elements. Further development will make it possible to design and print organs of the human body.

Relatively recently, a new invention has appeared in the field of printing, which makes it possible to create three-dimensional figures of varying complexity and configuration. This significant discovery made a huge contribution to the development of all spheres of human activity. Printing three-dimensional parts from polymer materials solved the problem in the manufacture of complex structural elements. Further development will make it possible to design and print organs of the human body.

However, this process is quite complex, so it must be properly ensured and controlled at each stage. A special work table is used for modeling and printing parts. If you want to improve its performance, you can assemble this element yourself with your own hands. We will talk about this in the article.

IMPORTANT: Usually there is a need to increase the power and surface heating temperature.

The content of the article

What size is needed for a 3D printer?

Before you start work, you need to correctly calculate the dimensions of the future table and the amount of material. For this, there is a special online calculator that allows you to accurately determine the length of the heating element. To do this, you need to enter the parameters: thickness, power and voltage. It is recommended to use values of 0.8 mm, 350 W and 55 V. In this case, you will get an optimal length of approximately 3.93 m. You can change various parameters to select the ideal balance of all indicators.

Before you start work, you need to correctly calculate the dimensions of the future table and the amount of material. For this, there is a special online calculator that allows you to accurately determine the length of the heating element. To do this, you need to enter the parameters: thickness, power and voltage. It is recommended to use values of 0.8 mm, 350 W and 55 V. In this case, you will get an optimal length of approximately 3.93 m. You can change various parameters to select the ideal balance of all indicators.

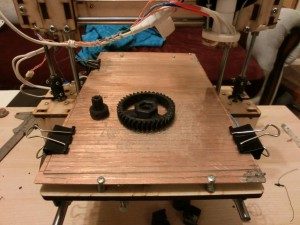

Materials and manufacturing instructions

Once you have decided on the dimensions of the future table, you can begin the manufacturing process. For this you will need the following set of tools and materials: wire of the required length, textolite, glass 2-4 mm (the thicker, the better when heated), a cover made of wood or cork, a grinding machine and a small grinder.

Stretch the wire around the entire perimeter, bending it in a spiral with a distance between the coils of 0.5 - 1 cm.

Stretch the wire around the entire perimeter, bending it in a spiral with a distance between the coils of 0.5 - 1 cm.- Connect the wires in the circuit to the power source.

- After this, cover the structure with glass.

- It is better to place a tree or cork mat underneath to prevent heating of surrounding objects.

- Try turning on the workpiece. If desired and necessary, you can adjust the power supplied to change the temperature.

IMPORTANT: After several attempts, you will be able to select the materials yourself and set the parameters necessary for the work. Don't be afraid to experiment, but follow safety precautions.