DIY folding table

Folding furniture is an excellent option for a home, cottage or picnic, because it does not take up much space and is easy to fold and transport. The solution is relevant for small apartments, where it is difficult to accommodate numerous friends and relatives, and there is nowhere to place drinks and food. And what is especially important is that anyone can do DIY folding table. This will require very little money, patience and accuracy.

Folding furniture is an excellent option for a home, cottage or picnic, because it does not take up much space and is easy to fold and transport. The solution is relevant for small apartments, where it is difficult to accommodate numerous friends and relatives, and there is nowhere to place drinks and food. And what is especially important is that anyone can do DIY folding table. This will require very little money, patience and accuracy.

The content of the article

Deciding on design and construction

For what reason is furniture assembled by yourself so popular? A homemade design is much cheaper than a purchased one, and it can have any design you want. For production, scrap materials are used, which opens up wide design possibilities. Tables can be made of wood, aluminum, or plastic, and they can be combined with each other.

As for the shape of the tabletop, it can be oval, round, square, but it is better to choose the classic rectangular one. The main role is played by the legs, since proper calculation of their sizes and reliable fixation ensure stability when unfolded and ease of folding.

Which material should you prefer?

The choice of one material or another depends on the requirements for the table, its size and expected load. The product must be:

- Durable. It must combine compact dimensions and at the same time withstand heavy weight.

- Easy. Its transportation should not take much effort, which is especially important for picnics, the location of which must be reached on foot.

The ideal option, which fully meets the stated requirements, is a profiled steel pipe, which is strong, durable and weighs relatively little. As an option, you can use aluminum, which weighs even less, and stores sell profiles of various sizes. But aluminum elements have disadvantages - their cost is higher and they are more difficult to process (the design requires special welding, which can be difficult to find, or rivets). Chipboard is quite suitable for a tabletop, but without proper processing of the ends, the table will not survive even one trip out of town. A worthy replacement is textolite, which is more practical, however, at the same time it is more expensive. Assembling a table at home from wood is the best option because it is inexpensive and easy to process. But be prepared for constant care of the furniture and careful processing, without which you can’t even dream of durability.

The ideal option, which fully meets the stated requirements, is a profiled steel pipe, which is strong, durable and weighs relatively little. As an option, you can use aluminum, which weighs even less, and stores sell profiles of various sizes. But aluminum elements have disadvantages - their cost is higher and they are more difficult to process (the design requires special welding, which can be difficult to find, or rivets). Chipboard is quite suitable for a tabletop, but without proper processing of the ends, the table will not survive even one trip out of town. A worthy replacement is textolite, which is more practical, however, at the same time it is more expensive. Assembling a table at home from wood is the best option because it is inexpensive and easy to process. But be prepared for constant care of the furniture and careful processing, without which you can’t even dream of durability.

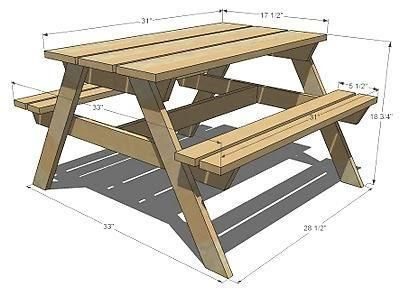

DIY folding picnic table

If a folding table is furniture that you will be assembling with your own hands for the first time, then it is better to take a closer look at simple designs. Wood should definitely be chosen as the manufacturing material, since its processing is simple, and almost everyone has the tools for this.In addition, the cost of boards and timber is low and there is a wide variety of final decorative finishing products.

Drawings and diagrams

As mentioned earlier, the simpler the table layout, the better it is for a novice master. The drawing is a primary and very important task, since it shows the dimensions of all structural elements, attachment points and finishing. In the process of work, you will need to constantly focus on it and gradually verify the results of the work. You can either develop the scheme yourself or download a ready-made one from the Internet, and then “tailor” it to your personal needs.

Stage-by-stage execution of work

To assemble a simple folding and camping wooden table, you will need: boards about 40 mm thick (the table top is easily made of plywood or 10 mm sheet chipboard), self-tapping screws, furniture bolts, nuts, handles, and hooks. In addition, you should prepare a tape measure, a pencil, sandpaper, an electric jigsaw and a drill. The process consists of several stages:

- Tabletop. To make it, you should cut out a fragment of chipboard or plywood of the required size, or cut several planks. The last option will require the preparation of 12 wooden planks 480 mm long.

- Frame. It is assembled from 4 wooden parts (2 pieces each, 400 mm and 1160 mm), which are placed on the tabletop and on each side should protrude 3 mm beyond its edges. The excess length is removed with a jigsaw, after which holes for self-tapping screws are drilled in the tabletop. To ensure that all parts have accurate dimensions, when cutting the planks, it is recommended to secure the structure with clamps.

- Intermediate bars. When the table unfolds, the legs rest on them.They are cut with a jigsaw 170 mm long, after which holes for self-tapping screws are drilled. To avoid the legs colliding during opening, supports are made for the second pair of legs, which are subsequently placed between the frame and the thrust bars.

- Connection between frame and tabletop. The components of the table are applied in compliance with the mounting points and sizes, and then fixed together with self-tapping screws. After installing the pads and stops, you need to drill 4 bolt holes.

- Legs. 4 wooden blocks 730 mm long are cut with a jigsaw, after which a 15-degree cut is made in their lower part, and a rounding is made in the upper part. Holes for bolts are drilled according to the drawing.

- Assembly of the entire structure. The legs are fixed in pairs one by one and then attached to the frame. Next, you should check their operation and make sure that they open smoothly. The final step will be screwing on hooks for cutlery or towels, as well as handles for comfortable transportation.

When tightening the screws, you need to slightly recess the caps inward for a more aesthetic appearance. As for bolted connections, you shouldn’t tighten them too much - moving elements should move freely. The final decorative finishing is preceded by careful processing of the entire product with sandpaper until it is smooth and free of burrs. It is strongly recommended to wear a protective mask and goggles while performing work.

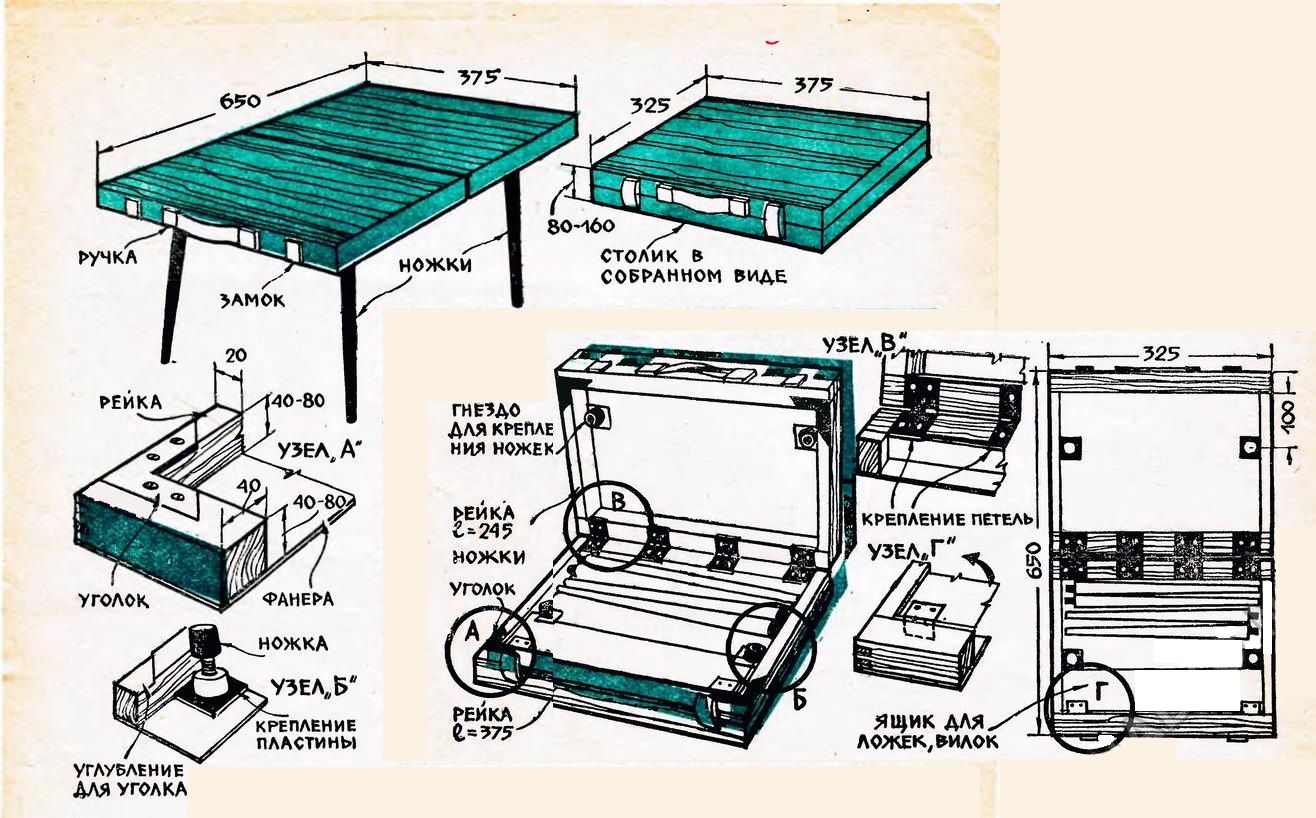

Suitcase table

An equally attractive option, which when assembled takes the form of a light and compact suitcase. The table top is made of plywood, which guarantees high strength, and when folded, you can put dishes or food inside.

Drawings and diagrams

The dimensions of the product are individual and are selected based on personal preferences and the volume of the car trunk. TOAs practice shows, a folding tabletop made of two elements measuring 70x70 cm is quite enough for a comfortable rest. As in the case of folding picnic furniture, first of all, a drawing is made indicating the dimensions of the elements and the places of their fastenings.

Stages of work

The initial stage is preparatory. All wooden elements must be sanded with sandpaper or a sander until completely smooth. You will need:

- sheet plywood 1 cm thick and dimensions 70x140 cm;

- 1 beam 800x4x4 cm;

- 1 handle;

- 2 suitcase locks;

- 4 screw-screw fastenings 100x6 mm for an open-end wrench;

- 4 nuts with a diameter of 6 mm;

- 2 furniture hinges;

- 30 screws 30 mm.

In addition, you will need an electric jigsaw, drill, pencil, tape measure, square, screwdriver, open-end wrench, level and chisel. Further work looks like this:

- Sheet plywood is cut into 2 equal parts 70x70 cm with a jigsaw, the timber is divided into elements for the subframe of 620 and 700 mm, as well as legs of 600 mm. Both subframes are assembled and fixed with self-tapping screws.

- Plywood is laid on the frame and secured with self-tapping screws around the entire perimeter.

- In the places where the frames join on the back side, recesses 2 mm deep are made with a chisel, after which furniture hinges are placed in them and fixed with screws.

- Holes with a diameter of 6 mm are drilled at the corners of the frame, and 4 screws are screwed into the ends of the legs. Next, they need to be inserted into the frame holes and secured with nuts. After this, suitcase locks are installed in the places where the tabletops adjoin the frame.

- The assembled structure is checked for horizontalness and the strength of fixation of all elements, after which the legs are unscrewed and placed inside the table, and the locks are closed. Finally, a transport handle is screwed on.

A wooden structure that is not coated with a protective agent may soon become unusable, since it is unstable to moisture, UV rays, and temperature changes. To increase the durability of the table, it is necessary to cover it with stain, varnish, paint or a special antiseptic composition. Particular attention should be paid to the countertop, because it is more exposed to adverse effects. In addition, the processed product has a more attractive appearance. Particular attention should be paid to storage conditions - when the table is not in use, it should be in a dry, clean place.

REFERENCE. Assembling a folding table takes an inexperienced person about 3 hours, and the financial costs are several times lower compared to purchasing ready-made furniture. It is worth noting that the structure, made by yourself, is much stronger and more reliable; it will make your vacation more comfortable for many years.