DIY kitchen table

By making your own kitchen table, you can save money. You just need to buy the materials. The result will not be long in coming, because you will receive unique furniture that will fit well into the interior of the kitchen.

By making your own kitchen table, you can save money. You just need to buy the materials. The result will not be long in coming, because you will receive unique furniture that will fit well into the interior of the kitchen.

The content of the article

How to make a kitchen table with your own hands

The process of creating a table with your own hands consists of the following steps:

- Choice of material. Preference is given to wood, but a metal or plastic structure can be made.

- Creation of drawings. Here you need to be as careful as possible, since this step is where the most mistakes are made.

- Assembly of the structure. All work is done according to the drawings.

What to make a table from

To create steel, solid oak is best suited. This material has a long service life and is strong. If used properly, such tables will last for several hundred years.

Another material is pine. It is soft enough, so it is easy to handle. This material should be chosen by novice builders. But the structure will not be as strong as one made from oak. When purchasing ready-made furniture boards, you do not have to cut and adjust the boards yourself. But a ready-made countertop will cost several times more.

The legs require the most durable and high-quality wood, since the weight of the entire structure and dishes will go directly to them.Another reason for choosing a strong material for the legs is that the table is often used as a stand if we need to glue or paint the kitchen ceiling. The structure will have to support the weight of a person.

Wood material is pre-treated with solutions to protect it from moisture. It also needs to be primed and painted. The color of the paint is not important; you can experiment with combinations of different coatings. If necessary, the table can always be repainted.

If you have a limited budget, laminated particle board is the best option. A person will have the opportunity to choose a decorative coating (plastic, wood). When you purchase a sheet of the required size, the need to cut out the board yourself will disappear. This will save a lot of time and effort. But it is necessary to choose a material with the most durable coating to protect it from damage.

Attention! You will also need to insulate the edge of the countertop, since moisture that gets there will cause the material to swell and rot.

What tools are needed?

To create the design you need the following tools:

- Bulgarian.

- Plane.

- Drill and set of drills.

- Roulette.

- Sanding machine.

- Jigsaw.

- Screwdriver.

- Sandpaper.

- Self-tapping screws.

- Glue.

- Clamps.

- Bolts.

- Dowels.

Drawings and measurements

If the size of the kitchen is standard (from 5 to 10 square meters), then 2 table options are best suited:

- Length 80, width 50 centimeters.

- Length 120, width 60 cm.

The average height in both cases will be 80 cm.

Typically, the size of the kitchen table is calculated depending on the size of the family. But we also need to add a few places for guests. If you often hold events and the number of guests is always large, it is better to use a folding table.

Calculations are made in this way, the number of people in the family is multiplied by 60 (this is the perimeter required for one person). The width of the table should be medium (about 60 cm). A narrow table will not fit many people, and it will also be difficult to serve them since there is little space. But too wide ones won’t work either. The problem is that there is a lot of unused space, which means the material is wasted.

Important! If you have chosen a round table, you need to calculate the circumference and draw up a diagram.

Table for the kitchen yourself: step by step

The process of making a regular kitchen table is as follows:

- First, buy several sheets of the necessary material.

- Now you should buy ready-made legs, or cut them yourself. For this purpose, bars with a cross-section of 5x5 cm are suitable. They are sanded with sandpaper and adjusted in height. You can also make the legs out of metal. It is desirable that they are covered with steel. To simplify assembly, use fasteners.

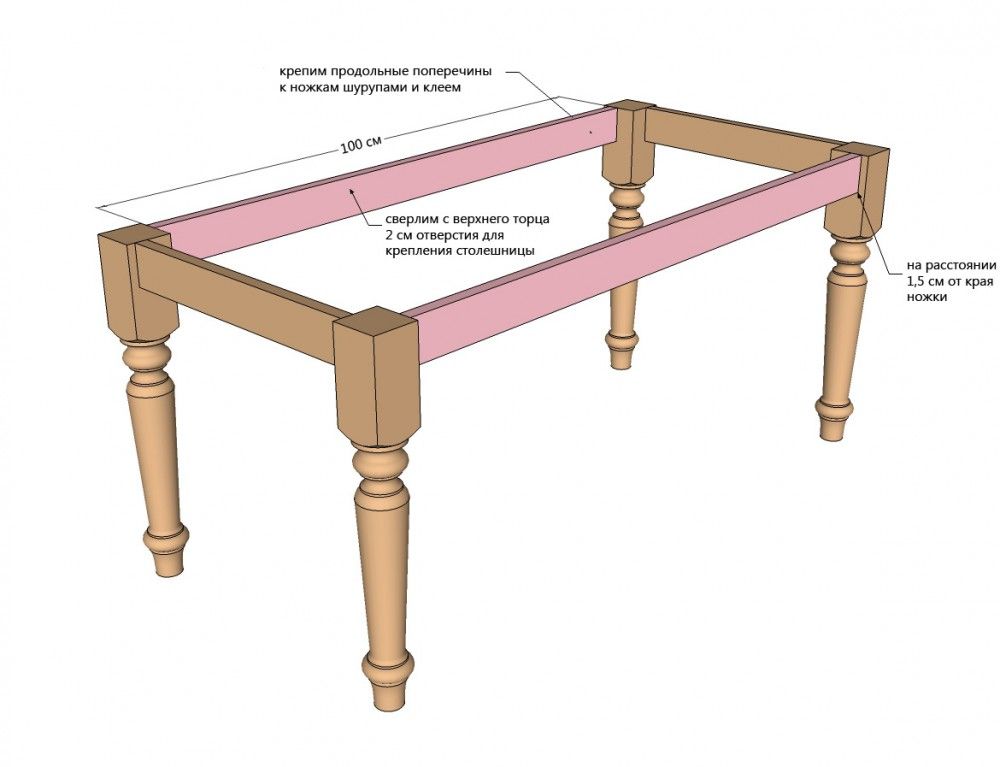

- If the choice is made of wooden legs, first of all you need to assemble the frame. This will ensure a good hold. Cross boards need to be attached to the legs. For fastenings, we use metal corners for the inside and self-tapping screws for the sides.

- The distance between the legs and the edge must be at least 100 mm. Wooden legs are installed using corners, and for iron legs we use fasteners that are sold in furniture stores.

- The wood must be treated with special substances to protect it from moisture. It is also coated with primer and paint.

- We close the sections of the sheet using furniture edges. A U-shaped edging made of polyvinyl chloride works well. Silicone sealant should be applied to the inside of the edge to protect it from water.We snap the edging onto the edge.

- Excess sealant must be removed.

- We close the resulting ends with plugs.

- When choosing a curved or round tabletop, you should use a flexible profile. It is attached using sealant (excess is removed as soon as the glue dries). Thanks to the flexible edging, there will be only one seam on the edge, and this will improve the appearance of the structure.

- To make the structure more reliable, you can use a T-shaped profile. But it requires a hand router, since you need to mill the groove right in the center of the entire edge. Such edgings will hide uneven cuts well. This will be great if they have a lot of cracks and chips. Such defects cannot be hidden with a simple edge.

- The structure is ready. It can be used.

Attention! Above is the process of making a standard kitchen table. But there are a lot of types of designs, so the work process may differ in individual cases. For example, you can make a round table on one leg (supports are attached to it so that the structure is stable). It all depends on your imagination.

If you know a little about construction, making a kitchen table yourself will be a piece of cake. It is important to pay attention to the quality of materials, since the table will have to withstand heavy loads.