How to make table legs with your own hands

Tables are an integral part of the interior. The variety of shapes, images and manufacturing styles make this piece of furniture not only necessary and important, but also a truly beautiful addition to the interior decoration of the room. Particular attention is paid to the legs, since they are the ones that have the most variations in design. If you have the time and, most importantly, the desire to decorate your table and give it exclusive touches, then we will help make it happen. How to replace the legs of this piece of furniture yourself?

Tables are an integral part of the interior. The variety of shapes, images and manufacturing styles make this piece of furniture not only necessary and important, but also a truly beautiful addition to the interior decoration of the room. Particular attention is paid to the legs, since they are the ones that have the most variations in design. If you have the time and, most importantly, the desire to decorate your table and give it exclusive touches, then we will help make it happen. How to replace the legs of this piece of furniture yourself?

The content of the article

Materials and tools for making table legs

Currently, there are up to 20 types and methods of making legs. Of course, you can limit yourself to the classic version. A rectangular table with 4 straight legs will look great and stand steadily in the center of the kitchen.

REFERENCE! The most stable table will be (like any other furniture on supports) standing on three legs, provided that it is evenly distributed over the area of the tabletop, and not in one line. Yes, exactly three, not four. Remember the geometry course! The plane is defined by three points. Therefore, 3 points always lie in the same plane of space, and therefore our structure will not swing from side to side under any conditions.It is more difficult to select four points so that they all coincide in one projection, so this design is more susceptible to loosening.

But despite the huge variety of manufacturing options, the set of tools and materials is always approximately the same. Prepare everything you need for carpentry work and get to work.

Materials:

- Wood beams of any size, but not less than 50×100 mm (almost any species are suitable, but for beginners it would be better to use pine, since it is easier to process).

- Metal pipes of rectangular or round cross-section.

- It is possible to use plastic blanks.

- Glue.

- Dye.

- Varnish or special impregnation for the finished product.

Depending on the choice of material and processing method, the following tools may be required:

- Tape measure with carpenter's pencil.

- Level.

- Drill with a set of drills for wood and metal (depending on the material).

- Saw, jigsaw.

- Sandpaper or sander.

- Screws and self-tapping screws.

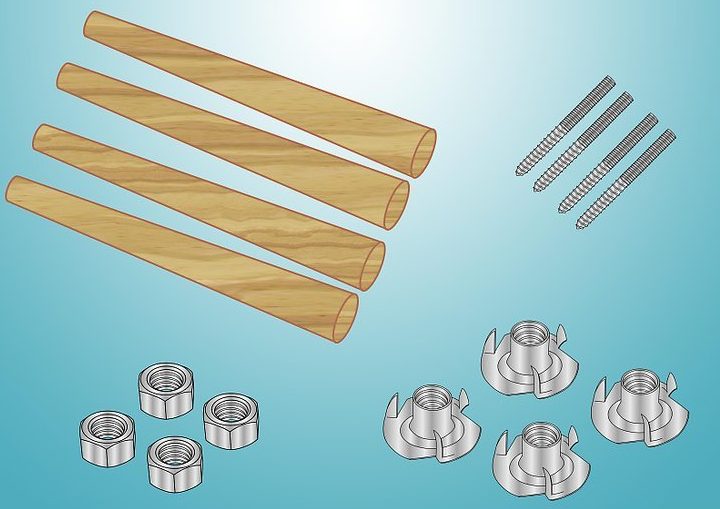

- Fastening systems.

There are many ways, each with its own advantages and disadvantages. We recommend that you work with wooden structures. They are easy to process, do not require much effort and have a fairly good service life.

Mounting methods

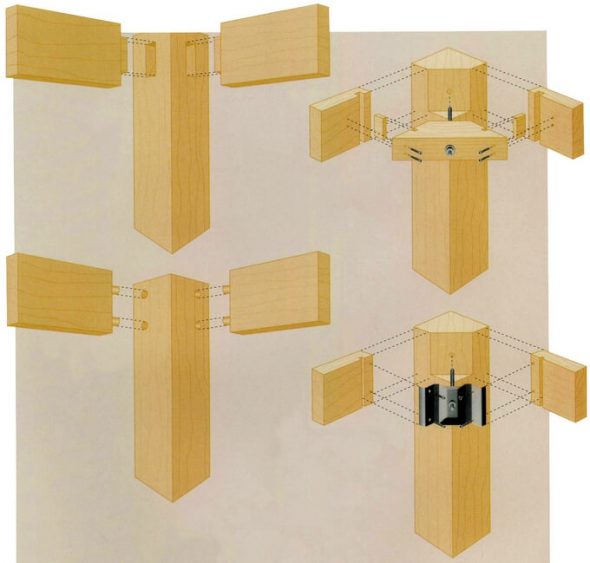

When choosing a material, it is necessary to choose the method of fastening the legs that will best meet the requirements of the table and will be easy to do with your own hands without the use of special tools. A correctly and efficiently assembled frame and fastening of the legs are key factors in reliable support and extending the life of the table. Therefore, special attention is required to this stage.

Let's look at the main types of fastening:

- When using surface plates. The leg is simply screwed into a special hole on a threaded metal dowel. Convenient for small, compact furniture.

- Application of T-nuts. The nuts are inserted from the side into which the leg will be screwed.

- Fixation to the tabletop using regular screws. Does not require additional materials and imitates the integrity of the product.

- Z shape holders. Conveniently and easily mounted to the body.

- The use of a special system of grooves and joining in them. This will require processing the wooden blank and preparing special holes and protrusions.

IMPORTANT! When carrying out work, it is necessary to use wood with an optimal humidity in the range of 6–8%. If the material is excessively damp or dried out, its dimensions may change and the structure may be damaged.

How to make table legs with your own hands

Of course, you can buy ready-made parts and attach them to the tabletop. It's simple and won't take much time. But if you want to make your furniture unique, you can try building the legs yourself. Let's look at two options that differ in level of complexity and style of execution.

Method without additional finishing. Simple rectangular legs for a classic table:

- Select 4 bars and cut blanks from them approximately 0.7 - 0.82 m in length.

- To make one leg, fasten the two parts with glue. For secure fixation, secure them in a vice.

- After coupling, the part should be given a strictly square shape; for this, cuts are made along the edges.

- Clean the wood from nicks and irregularities using sandpaper.

- To give a narrowed shape and attach the legs with screws, cut off part of the material from the top edge of the product at an angle.On two legs on the right and two on the left. We received a complete support kit.

- Attach it all with screws or using one of the methods described above.

IMPORTANT! When working with glue, ensure good ventilation and follow safety rules!

The second method differs only in that we give the workpiece a certain shape with curly cutouts on the frame (after we have glued the two parts of the block together):

- We prepare a drawing diagram of the future work of art in advance. This can be decorative carving, cuts along the entire length, or decoration using inlay.

- We carry out steps 1 to 3 above.

- We transfer the dimensions from the drawing to the part.

- Using a machine or a semicircular chisel, we cut off the “extra parts” and create a shaped image for the leg.

- We process the entire surface with a grinding machine or emery to make it smooth.

- We cover it with varnish or wood paint.

- We repeat the same for the other 3 parts.

This method is much more complicated, but the result is much more beautiful. You and your loved ones will definitely like it and will surprise your guests.