DIY milling table

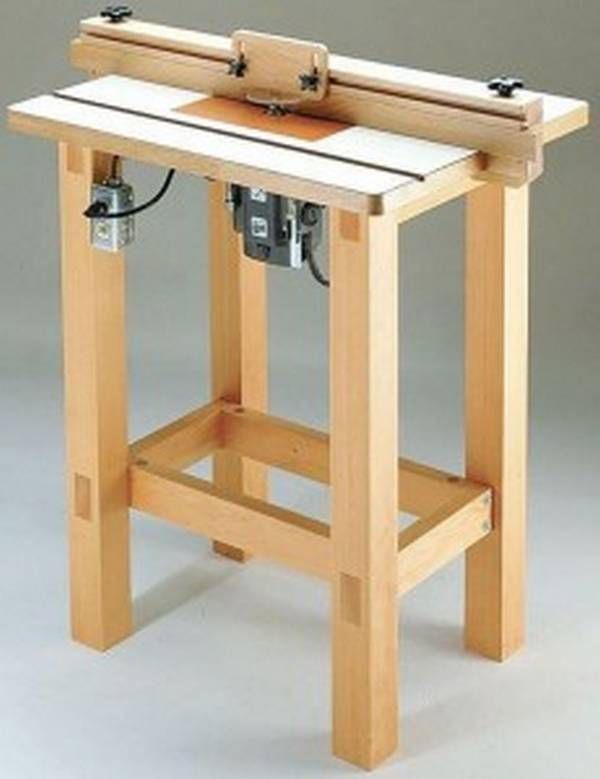

The question of how to assemble a table for a household milling machine yourself arises for home craftsmen. This is quite logical. This is an installation in which the milling device is mounted permanently, and the workpiece moves along a specially made table.

The content of the article

Designs and types

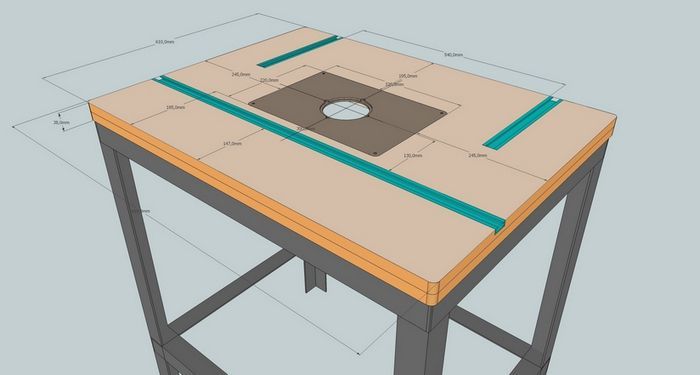

In practice, there are many options for the design of milling barrels. Home craftsmen create unique designs with their own hands to suit their needs. But all options have one subtlety that unites them - the dimensions of the table. For example, a table with dimensions of 900*480*300 mm can be used.

Table type

Before performing work, you should understand what kind of table you actually need. In practice, the following types of tables are used:

- permanent;

- portable;

- aggregate.

If a home craftsman plans to work outside the home, then a portable product is quite suitable for him. It can be installed on a chassis and easily moved around the workshop. For a workshop located in a small room, an aggregate option would be good, which is an extension of the table top of the saw table or its rotary design.The practicality of using a router mounted on a table is expressed in the improvement and reliability of working with wood and, of course, in the speed of manufacturing parts. The operating principle of this device is as follows: the router is rigidly installed, and the workpiece moves relative to it. This design provides ample opportunities for processing workpieces. As a result, the workpieces are produced with a quality no less than in a production workshop equipped with the appropriate equipment. When creating a milling table, it is advisable to take into account the possibility of its modernization. It doesn’t hurt to think about the arrangement of auxiliary drawers, which will only add additional comfort at work.

If a home craftsman plans to work outside the home, then a portable product is quite suitable for him. It can be installed on a chassis and easily moved around the workshop. For a workshop located in a small room, an aggregate option would be good, which is an extension of the table top of the saw table or its rotary design.The practicality of using a router mounted on a table is expressed in the improvement and reliability of working with wood and, of course, in the speed of manufacturing parts. The operating principle of this device is as follows: the router is rigidly installed, and the workpiece moves relative to it. This design provides ample opportunities for processing workpieces. As a result, the workpieces are produced with a quality no less than in a production workshop equipped with the appropriate equipment. When creating a milling table, it is advisable to take into account the possibility of its modernization. It doesn’t hurt to think about the arrangement of auxiliary drawers, which will only add additional comfort at work.

Step-by-step algorithm

The use of home milling devices significantly expands the capabilities of the home craftsman in terms of processing wood and soft materials. The first thing you need is a base on which the tabletop will be installed. To assemble the frame for the milling table, a metal profile of square or rectangular cross-section is used. The use of such a profile will give the structure additional rigidity and reliability. To assemble the frame, it is advisable to use electric arc welding. A mounting plate will be installed at the designated location. The main requirement for this procedure is to ensure a high-quality surface of the countertop.

The seat for the plate must be rounded. This can be done using an ordinary file. After the mounting plate is adjusted, holes are made in it using a router in which the router itself will be installed.It is necessary to make selections in the lower part of the tabletop; subsequently, a dust collector casing will be installed in them. If the master plans to use additional devices, then it’s time to make mounting holes or grooves for them. After the work has been completed, you can begin assembling the table. The sequence of actions is as follows: the milling unit is brought in from below and fixed on the tabletop. It should be noted that the screw heads must be recessed. After installing the milling tool, you can attach the tabletop to the frame. The presence of a clamping device in the design of the tabletop will not hurt. It is useful when processing large workpieces. To assemble such a device, you will need rollers or a ball bearing. It is strengthened in a holding mechanism, which is fixed at a certain distance from the tabletop. The use of such a device will ensure tight pressing of a semi-finished product with large dimensions when it is passed through during processing. This will not only increase processing accuracy, but also increase the level of operational safety.

The seat for the plate must be rounded. This can be done using an ordinary file. After the mounting plate is adjusted, holes are made in it using a router in which the router itself will be installed.It is necessary to make selections in the lower part of the tabletop; subsequently, a dust collector casing will be installed in them. If the master plans to use additional devices, then it’s time to make mounting holes or grooves for them. After the work has been completed, you can begin assembling the table. The sequence of actions is as follows: the milling unit is brought in from below and fixed on the tabletop. It should be noted that the screw heads must be recessed. After installing the milling tool, you can attach the tabletop to the frame. The presence of a clamping device in the design of the tabletop will not hurt. It is useful when processing large workpieces. To assemble such a device, you will need rollers or a ball bearing. It is strengthened in a holding mechanism, which is fixed at a certain distance from the tabletop. The use of such a device will ensure tight pressing of a semi-finished product with large dimensions when it is passed through during processing. This will not only increase processing accuracy, but also increase the level of operational safety.

Deciding on the design, drawing

A homemade milling cutter is a simple, but still technical device, and before its manufacture it is advisable to prepare drawings; if difficulties arise with this, then working drawings can be found on the appropriate resources on the Internet.

REFERENCE. It will be much easier for you to work with ready-made drawings.

If you really want, you can make a milling table from an ordinary workbench. But, as practice shows, it makes sense to make a separate structure. This, by the way, is easily explained. During operation, an electric router creates serious vibration loads.Therefore, the tabletop is resistant to external influences and durable. We must remember that this device is mounted from the bottom and therefore there must be a certain unoccupied volume under it. When installing milling equipment on a newly created table, a mounting plate is used, which has the necessary reliability and rigidity. To produce the mounting plate, it is advisable to use steel sheet, sheets, MDF, plywood or textolite.

Structurally, a milling machine is a frame with a tabletop installed on it. In practice, many home craftsmen equip this design with tool boxes to store the technological devices required for productive work.

We must not forget about local lighting. To do this, it is permissible to mount a lighting device on the plane of the tool table that provides sufficient visibility at the milling site.

Most modern devices have grooves already made on the base; they are used to secure the tool to the mounting plate. If there are no such holes, then you will have to make them and cut threads into them. When installing the device on the machine, all safety precautions must be observed.

Necessary materials

To make your own countertop, you will need to use the following materials - rolled metal or bars made of wood. To process them you will need to use an angle grinder. It wouldn’t hurt to have a hacksaw for metal; of course, all work should be carried out using a measuring tool - a tape measure, a steel angle and a level.

The frame for the tabletop is made of wooden blocks or metal profiles.It should be noted that a wooden structure will have less rigidity and strength; unfortunately, the wood may dry out. We must not forget about the vibration that occurs during operation of the router.

To attach the tabletop to the base, you will need to use threaded fasteners; when installing it in place, you need to make sure that the heads are recessed into the body of the tabletop.

Make a table top

One of the key characteristics of a router table is its height above the floor. Modern ergonomics suggests that the optimal height of the tabletop from the floor lies in the range from 800 to 900 mm. Adjustable feet can be attached to the table supports. They will allow you to adjust the height of the tabletop.

To obtain a working table for the milling device, take the top cover from an unnecessary kitchen table. They are made of chipboard with a thickness of 26 or 36 mm. The surface of such a plate is covered with wear-resistant plastic. This coating ensures normal sliding of the semi-finished product during processing. For the table it is permissible to use MDF or chipboard boards with a thickness of 16 mm and above.

The hole for the cutter to extend is difficult to make using a round cutting tool, so it will have to be modified to the required dimensions using a file.

Building a solid foundation

The lower part of the frame must be designed and manufactured in such a way that nothing interferes with the worker. For the most part, the bed has the following dimensions: 900x500x1500 mm. The base of the milling head must be resistant to external influences, in particular vibration. It is this component of the milling installation that accounts for the bulk of the load.The base is a frame made from rolled metal or wooden blocks. The desktop will be installed on this frame.

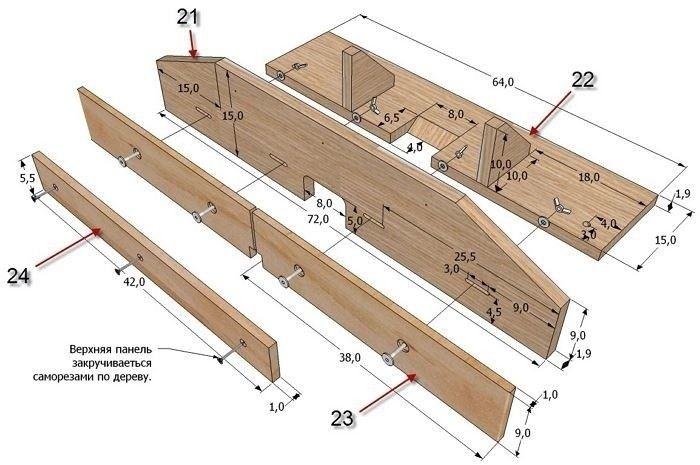

A multi-purpose table begins to be assembled by installing the tabletop on an already assembled frame. The installation plate is to the place where it should be installed in accordance with the requirements of the working documentation and its silhouette is outlined. Then, following the outline, you need to select a layer of material. For this, a manual milling machine with a 6–10 mm cutter is used. The size of the depression should be such that the mounting plate lies flush with the plane of the work table.

We cut into the working base

Since the tabletop has a significant thickness of 16 mm, the installation plate should be slightly smaller. At the same time, it must be durable, despite the fact that you are making a table for manual use. To make the plate, sheets of steel or textolite with a thickness of 4–8 mm are used. The dimensions of the mounting plate must correspond to the size of the base of the milling unit. The joining of the milling device itself and the mounting plate is carried out through the holes that already exist in the base of the router. If they are not there, you will have to drill and tap them.

The dimensions and placement of the lugs for joining the mounting plate and the housing must be proportional to each other. In order to avoid errors in the manufacture of the mounting plate, it is advisable to make a sketch of it in advance, which indicates its dimensions, the placement of holes and the size of the thread are also indicated.