Installation of LED strip in the kitchen under cabinets

Installing an LED strip is a fairly simple task, and the effect obtained as a result of a little effort exceeds even the wildest expectations. After all, LEDs are 5 times brighter than conventional incandescent lamps, so they can serve not only as additional, but also as primary lighting.

Installing an LED strip is a fairly simple task, and the effect obtained as a result of a little effort exceeds even the wildest expectations. After all, LEDs are 5 times brighter than conventional incandescent lamps, so they can serve not only as additional, but also as primary lighting.

The content of the article

Selecting LED strip

The brightness and color of the backlight are selected depending on individual preferences. But there is a characteristic that the interior does not affect - moisture resistance. It can be identified by the IP marking, where the letter designation is followed by numbers. The first indicates the degree of protection from dust, dirt and mechanical damage. The second is for moisture resistance. Both indicators are rated on a scale from 0 to 9. Thus, an LED strip marked IP20 has poor protection against mechanical impact and a complete lack of waterproofing.

ATTENTION! For lighting kitchen cabinets, it is recommended to select strips with a high level of resistance to dirt and humidity. IP 65 and higher are suitable for installation in the kitchen. If the parameter values are lower, the LEDs must be placed in a special protective box.

SMD LEDs are used for backlight strips. The number following this abbreviation indicates the size of the diodes. For example, SMD 5050 means that elements measuring 5x5 mm are built into the tape.

The brightness of the lighting depends on the density of the diodes. There can be from 30 to 240 pieces. per linear meter. The more of them and the larger they are, the higher the energy consumption of the tape, but also, accordingly, the brighter it glows.

REFERENCE! To organize full illumination of the work area, it is recommended to select LEDs with 120–240 diodes per meter. For decorative purposes, 30–60 is enough.

Tapes are also classified according to the type of glow:

- Full color - diodes consist of several crystals (up to 4) and can change color depending on the user settings.

- Monochrome - bright single-chip diodes. Only the light intensity can be adjusted.

The second type of tapes is characterized by a narrow spectrum of luminescence, so they can distort the natural color of products. Full-color ones have a different drawback - when the spectrum changes, only part of the crystals work, which reduces the brightness of the backlight.

White monochrome operates on the same principle as a conventional fluorescent lamp. Depending on which shade is chosen, the temperature of the glow may differ. As a result, the streams of light emanating from the tape can be warm or cold.

The printed circuit board is usually white. But there are different color solutions, so choosing the optimal option that harmoniously matches the furniture is not difficult.

Selecting a power supply

The LEDs are powered by a 12 or 24 V mains voltage, so to connect to a regular outlet you will need a converter. Determining the parameters of a transformer is quite easy: the manufacturer indicates the power per linear meter of tape, which should be used as a basis for further calculations. If the value is 12 W and the strip length is 4 m, then the total power will be 48 W.To this number you need to add another 20–25% of the reserve. Therefore, in the design case, a 60 W transformer will be needed.

Power supplies differ in design. For the kitchen, it is better to choose sealed ones, in a plastic or aluminum case. Open blocks in a perforated casing are cheap and powerful, but require additional waterproofing. If you are interested in network units that do not require installation, then you should pay attention to the fact that for each tape you will need a separate device.

ATTENTION! Protection against voltage surges in the network will help increase the service life of LEDs.

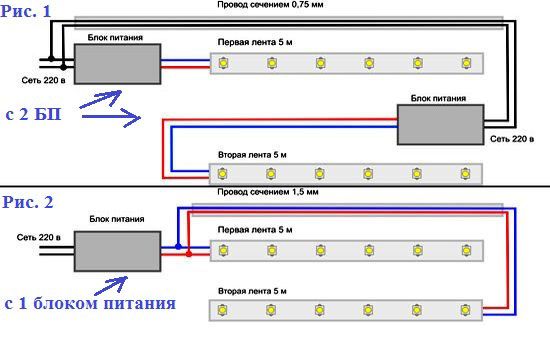

When connecting several tapes, voltage amplifiers will be needed. If you include a dimer in the electrical circuit, then it will be possible to regulate the brightness of the LED due to a smooth change in power.

What is required to install LED backlighting

Preparation for independently connecting additional lighting includes purchasing:

- LED coils;

- transformer (power supply);

- dimer;

- cable with a cross section of 0.74 mm.

If the LED strip is poorly protected from moisture and dust, you will also need an aluminum profile for mounting the LED.

During the installation process you will need:

- soldering iron;

- solder and rosin;

- scissors;

- insulating tape.

Usually the back side of the LED is self-adhesive. But if the reliability of such fastening is in doubt, you can additionally fix it on the surface using electrical mounting brackets. If you use a profile, a drill and self-tapping screws will be useful.

DIY LED strip installation in the kitchen

Organizing additional lighting is not a difficult task, but requires care. When connecting circuit elements, it is important to observe polarity.The tape itself must not be twisted or kinked. If you need to make a sharp bend, then it makes sense to make a cut and connect the terminals with solder or a connector.

Other installation tricks include:

- minimizing the number of adhesions;

- mandatory insulation of conductive paths at connection points;

- protection of the power supply from overheating;

- parallel connection of strips whose total length exceeds 5 m.

And most importantly: the flexible board can only be cut in places marked by the manufacturer. Otherwise it may be damaged.

Installation procedure:

- Cutting the tape into strips of the required length and exposing the extreme contacts.

- Solder the cables and insulate the connection point.

- Fixation of LEDs in the designated area.

- Connecting wires to the dimmer (if necessary) and the power supply.

If all work is carried out correctly, the backlight will last no less than the period guaranteed by LED manufacturers - about 10 years.