How to install a door closer on a kitchen cabinet

Kitchen furniture is subject to daily active use, which requires its serviceability and ease of use. For these purposes, closers are provided that ensure smooth closing of doors; they help avoid sharp sounds and impacts, thereby extending the service life of the cabinets. In addition, arbitrary opening and distortion of the doors is prevented, and most importantly, the work of installing them can be done independently. How to install a door closer on a kitchen cabinet and what will be needed for this?

Kitchen furniture is subject to daily active use, which requires its serviceability and ease of use. For these purposes, closers are provided that ensure smooth closing of doors; they help avoid sharp sounds and impacts, thereby extending the service life of the cabinets. In addition, arbitrary opening and distortion of the doors is prevented, and most importantly, the work of installing them can be done independently. How to install a door closer on a kitchen cabinet and what will be needed for this?

The content of the article

Types of door closers for kitchen furniture

Closers are characterized by high reliability and durability, subject to proper installation and appropriate attitude. There are two types:

- Gas. More affordable, they slow down the closing door at the very end of the stroke. The main advantage is that it is almost impossible to damage such a mechanism.

- Oily. Available in a wide price range and ensure smooth closing of the door.

As for the design of the device, it can be different - from stylish miniature to not very attractive in appearance. Both varieties confidently withstand significant loads without losing their performance characteristics.

How to choose the right option?

When choosing a closer, you should pay attention to the manufacturer of the product, its installation method and type. As for manufacturers, there are a lot of them on the market, but most produce pretty good products, so the choice can be based on personal preferences. More expensive and high-quality products, even if broken, will not release gas or oil and will not cause harm to your furniture. The service life of oil closers is longer, as is their cost. At the same time, given that the viscosity of the oil increases under the influence of low temperatures, they should be given preference only if the room is properly heated.

When choosing a closer, you should pay attention to the manufacturer of the product, its installation method and type. As for manufacturers, there are a lot of them on the market, but most produce pretty good products, so the choice can be based on personal preferences. More expensive and high-quality products, even if broken, will not release gas or oil and will not cause harm to your furniture. The service life of oil closers is longer, as is their cost. At the same time, given that the viscosity of the oil increases under the influence of low temperatures, they should be given preference only if the room is properly heated.

Choosing furniture hinges

Fasteners should be selected based on the thickness of the doors, their weight, and the material used to make the hinges. The most popular are 4-hinged overhead devices, which are suitable for any furniture with hinged doors. There are several varieties:

heel;

heel;- invoices;

- gallery;

- semi-overhead;

- piano;

- deposits, etc.

The solution is selected according to the dimensions of the furniture and the material of its manufacture. It would also be advisable to purchase hinges that match the design of the cabinet.

Self-installation of hinges on kitchen cabinets

Before you start work, you should prepare a drill with drills, a screwdriver, a tape measure, a pencil, self-tapping screws and screws (as a rule, they come complete with hinges). Kitchen cabinets should be secured properly. The fixation method is selected based on the door material, as well as their weight - heavy parts or whose height exceeds a meter will require at least 3 hinges, while 2 are usually used. The process looks like this:

- Using a tape measure, a minimum of 10 cm is set aside from the upper and lower edges of the doors, which will prevent the sash from quickly becoming loose.

- The loops are applied to the place of future fixation and markings are applied with a pencil for a more precise connection.

- Holes for the cups are drilled - a depth of 1.2 cm is sufficient, after which they are inserted and screwed with screws. It is important to hold the screwdriver strictly perpendicular to avoid uneven installation.

- The door is hung on the body. It is better to do this on a flat surface, while the side of the furniture on which the hanging bar is fixed should be horizontal.

There is no need to be alarmed if the doors do not move easily when first opened - after some time the hinges will develop, which is also facilitated by lubricating them with machine oil.

Leveling and Adjustment

To complete the installation of the hinges, they should be adjusted in 3 planes:

- horizontally - necessary for the normal movement of the door from right to left or vice versa, so that there are no gaps between it and the furniture body;

- vertically – movement in a vertical position, which is also adjusted during operation, since the doors sag over time;

- relative to depth - required to strengthen or weaken the pressure to the body.

Modern hinges are very easy to adjust - they have oval holes that allow you to easily move the product by slightly loosening the screws with a screwdriver.

Gas lifts - what are they and what are their features?

Gas lift is a shock-absorbing mechanism whose purpose is to open doors and hold them in that position. Thanks to him, this does not require much effort. The design is completely sealed - nitrogen is placed inside during the production of the product, and if it is damaged, it cannot be repaired. The advantages of gas lift include:

reliable fixation and smooth movement;

reliable fixation and smooth movement;- easy opening even in the absence of a handle;

- long service life;

- compatibility with any door material.

They give kitchen cabinets a stylish look, allow them to be used quietly, while maintaining the integrity of the elements and extending the life of the furniture.

How are they installed?

The gas lift is installed in strict accordance with the instructions, which is the key to its uninterrupted operation. It is important to understand:

- each facade will require 2 gas lifts, which avoids its distortion;

- the 100N marking indicates the need to mount the cabinet to the wall and is used only for heavy and massive doors;

- installation of products is carried out at the very end, when other fittings are already installed.

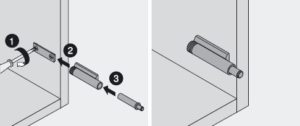

The installation process is very simple - you need to fix the fasteners for the gas lift, then put the product on them and press until it clicks.

Adjustment is necessary for comfortable and proper operation of the door, as well as to avoid it touching the ceiling when opening upward. For this purpose, a special screw is located on the gas lift body, which allows you to vary the tightness of the door to the body and its closing by changing the speed of movement of the working material in the sleeve.

Installing door closers and hinges with your own hands is not particularly difficult and only requires compliance with simple rules. Their design is simple and, coupled with patience and accuracy, will quickly achieve the desired result.