How to assemble a corner cabinet: step-by-step instructions

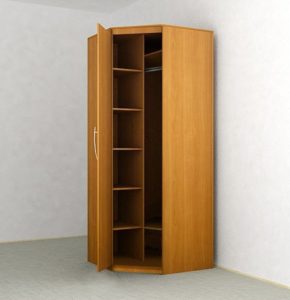

A corner cabinet is a great way to rationally distribute room space in a small room. Another advantage of this furniture is that the cabinet can be assembled with your own hands, without using the services of specialists.

A corner cabinet is a great way to rationally distribute room space in a small room. Another advantage of this furniture is that the cabinet can be assembled with your own hands, without using the services of specialists.

The content of the article

Assembling a corner cabinet

Corner structures are most often chosen for small rooms or for rooms with non-standard dimensions. These products differ from classic cabinets in their design features, and have their own advantages and disadvantages.

To assemble the structure with your own hands, you need to note the features of this piece of furniture:

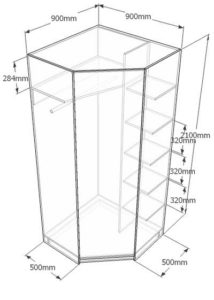

- Before choosing a model for a specific room, you need to measure all dimensions: width, height, depth;

- in the corner cabinet there are four walls, unlike traditional products: two are located near the wall, the remaining two are supporting parts located on the sides;

- corner models can be equipped with sliding and swing doors;

- furniture can have different shapes.

What materials and tools are needed

The lifespan of the cabinet will depend on the material used to make the cabinet. All materials are divided into two main groups:

- Fiberboard.

- natural wood.

Attention! Natural materials look more attractive, but are quite expensive. Externally, these models are made in a sophisticated style that resembles retro. Furniture made from fiberboard is a little worse in quality, but has a huge variety of colors. Installation of fiberboard products is much easier.

Self-assembly of the structure will require certain tools:

- a screwdriver is required to screw in screws and fasteners when arranging shelves;

- a hammer drill or electric drill is needed to make holes in wood;

- a hacksaw is required for cutting material;

- a screwdriver is most often used for deep seating screws;

- a set of hexagons is needed to fasten the fittings.

Important points when assembling a corner cabinet

Features of manufacturing a corner cabinet:

- You can rely on ready-made drawings or create your own.

- Corner products require special care during the creation of the diagram and assembly, in contrast to the classic options, so an inexperienced craftsman may have problems. If there is not enough experience, then it is advisable to entrust the cutting of all elements to a specialist.

- In order not to assemble a smaller element, it is necessary to take into account the thickness of the saw blade.

- The thickness of the walls is chosen to be at least 20 mm. Otherwise there will be insufficient structural strength.

- When creating a drawing, you need to pay attention to the unevenness of the floor. If it is crooked, then gaps will appear between the doors. For a swing system, this can be corrected by adjusting the canopies, and for a sliding system, by changing the height of the rollers.

- Door guides must be mounted parallel.

- Care must be taken when marking and attaching guide rails for drawers.

- Attaching the mirror should begin by gluing the seal along the contour.

- The laminate is fixed to the fiberboard sections with an iron.

Assembly depending on the design and model of the cabinet

Assembling the structure is quite simple, you just need to know the main points and stick to the drawings.

Before drawing up a diagram, you need to determine the shape of the future model:

- triangle;

- L-shaped;

- trapezoid

There is also a model with 5 walls.

A serious mistake is made by people who purchase poor quality rollers or do not use steel profiles because of their supposedly expensive cost.

If you need to speed up the assembly process and do the work accurately, it is advisable to order cutting of wooden sheets in a workshop. The size of the cabinet must correspond to the area of the room and the principles of filling. So, for shirts and sweaters you will need a compartment larger than 90 cm and not lower than 150 cm.

The shape of the cabinet model has virtually no effect on its production. First of all, metal corners are attached that will hold the side parts, preventing them from deviating from the level.

To assemble the frame, ready-made elements are used. Then the guides are attached and the doors are installed on the rollers.

The interior assembly of the cabinet is just as important as the construction of the box.

In this case, the following stages of work are performed:

- install brackets;

- fix the shelves in the required place;

- install the fittings (partitions first, after hangers and shelves, handles are screwed in last).

Vertical partitions, having installed them in the guides, must be secured with hangers. You should not neglect the stiffeners, especially since it is necessary to install them in places where shelves and drawers will be located.Replacing a steel profile with bars is possible only in special cases, and the wood must be well dried, otherwise the cabinet will be completely deformed during shrinkage.

This assembly scheme is also used without significant changes during the manufacture of plasterboard cabinets, but some differences still exist.

The initial stage of work in this case will not be the installation of the frame, but the marking of the ceiling and floor surfaces, taking into account the drawing. It is advisable to mark with shock-absorbing silicone tape and precisely fasten metal profiles along it.

After the workpieces are installed in their places and secured with self-tapping screws (screwing them in increments of 25 cm). You need to make sure that the caps go a millimeter deep into the drywall.

Important! Do not make your own or order cabinet doors until the structure is completely ready. Otherwise, you may find that the dimensions have changed slightly and the doors do not fit.

Afterwards you need to take care of priming the drywall, sealing the seams with plaster, installing corners, puttying, drying, sanding and finishing.

Step-by-step instructions for assembling a corner cabinet

Assembling a corner cabinet step by step:

- Draw a drawing, taking into account proportions and scale. All parameters need to be displayed.

- Make a stencil from plywood in the shape of a triangle. He will be able to help you correctly apply markings, determine the boundaries of the structure and the dimensions of the doors.

- Frame assembly. At this stage it is necessary to use a level. If the verticality of the structure is violated, then after a while the doors will jam or they will begin to open spontaneously.

- Fastening the side parts.

- Marking the locations of shelves and racks, their fastening.

Beginners are advised to first make a cabinet layout out of cardboard.This will make it possible to avoid inaccuracies at the design stage. Taking into account the cardboard blanks, you can subsequently order sawing of the parts.

Corner cabinets not only make it possible to rationally use the entire area of the room, but are also a true decoration in any room, emphasizing the taste and individuality of its owner.