How to assemble a metal rack

The metal rack is a universally collapsible structure that allows you to rationally distribute items in industrial, warehouse and garage types of premises. Consists of racks with supports, brackets, shelves, thrust bearings. The design is divided into types by type:

- Mobile.

- Stationary.

- Frontal.

- Angular.

- Palletized.

- Pallet.

- Shelf.

The content of the article

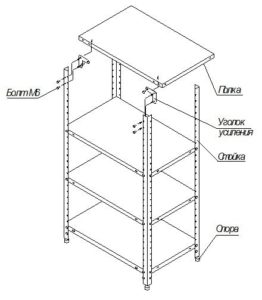

Instructions for assembling a metal rack

The prefabricated rack is selected according to individually required parameters (size, height, width, depth). Selected for a specific purpose, great for storing books, cans of preserves, car parts and tools. The metal product is lightweight and yet highly resistant to stress. Shelves with one stiffening rib can withstand up to 90 kg, with two ribs - up to 120 kg.

The prefabricated rack is selected according to individually required parameters (size, height, width, depth). Selected for a specific purpose, great for storing books, cans of preserves, car parts and tools. The metal product is lightweight and yet highly resistant to stress. Shelves with one stiffening rib can withstand up to 90 kg, with two ribs - up to 120 kg.

The main advantage of using a metal rack is saving space. According to cost criteria, it belongs to the budget category. Replacing a worn-out part in it is not difficult.

Thanks to galvanized elements, the rack is suitable for installation in rooms with any temperature and humidity level. It is not susceptible to corrosion, does not mold, is fire resistant, and has a long service life.

How to assemble a metal rack? Installation is much simpler than assembling cabinet wooden furniture.Occurs using a minimum of additional tools; An electric screwdriver or open-end wrench is sufficient. For some models, fastening is carried out on hooks.

IMPORTANT! We assemble the structure strictly on a horizontal surface.

How to assemble a rack? Assembly steps:

- Prepare the components and carefully study the instructions.

- Bolt the supports with legs and thrust bearings to the main posts.

- Fix horizontally between two shelf supports.

- We fasten them, the structure will become more stable.

- We fix intermediate shelves and blank walls.

- Tighten all the bolts.

IMPORTANT! When installing, pay attention to the symmetry of the parts and fixation without distortions.

After all stages of assembly, check the rack for stability.

Features of installing shelving at an angle

The corner type of rack is perfect for installation in small spaces. For example, it is suitable for a loggia for pots with indoor plants or narrow cellars for arranging jars of pickles.

The corner type of rack is perfect for installation in small spaces. For example, it is suitable for a loggia for pots with indoor plants or narrow cellars for arranging jars of pickles.

The collection principle is similar to stationary racks, only a few points differ:

- In the place where the corner shelf is attached, you need to install additional reinforcing metal corners, firmly securing them.

- Fix the corner shelves to the racks using corners.

- Connect the structure with thrust bearings.

- Push the vertically placed rack into a corner and evaluate the correctness of the assembled structure.

Installation of additional elements

Additional details are:

Additional details are:

- Limit bar. It is fixed to the main posts.

- Cross divider. Places vertically on a shelf.

- Longitudinal divider. Fixed to the main posts.

The set may also include:

- Separators;

- Walls;

- Sloping shelves;

- Awnings;

- Mesh shelves;

- Drawers.

Assembly safety rules

First of all, before starting assembly, you need to familiarize yourself with the safety rules.

First of all, before starting assembly, you need to familiarize yourself with the safety rules.

The installation process must be approached with extreme caution. Let's look at the basic recommendations for safe assembly of metal shelving:

- Get personal protective equipment (helmet, gloves, hard shoes).

- The place where the assembly will take place must be spacious, without the presence of third-party objects.

- Good lighting is necessary.

- Use only serviceable tools that are free of any defects.

- The location for installing the future structure must be level.

- Each subsequent tier is installed after the previous one is completely installed.

- There should be no rush during installation.

- You should begin installation only in a sober state.

- Assembly should take place in a place protected from children.

- When installing the rack, the assembled structure should not be unstable; it is recommended to place additional support under the base or secure the rack to the wall with additional pins.