DIY plywood rack

Books and cute figurines, photo frames and memorabilia create coziness and warmth in the house. Sometimes there are so many of them that it is not always possible to allocate a separate place for each, and as a result, the house turns into a warehouse of things that end up in the most unexpected places. A similar problem can be solved using a regular rack.

Books and cute figurines, photo frames and memorabilia create coziness and warmth in the house. Sometimes there are so many of them that it is not always possible to allocate a separate place for each, and as a result, the house turns into a warehouse of things that end up in the most unexpected places. A similar problem can be solved using a regular rack.

The content of the article

What types of racks are there?

A rack is a very functional piece of furniture that is used in literally every home; such a product is valued because of the many shelves and the ability to place it in any part of the home. You can buy any furniture in stores, but rather than overpay the manufacturer and a bunch of intermediaries, it’s easier to make it yourself, especially since the design itself is simple, you just need to decide on the type of product. Think about where it will be located; most often they are located:

A rack is a very functional piece of furniture that is used in literally every home; such a product is valued because of the many shelves and the ability to place it in any part of the home. You can buy any furniture in stores, but rather than overpay the manufacturer and a bunch of intermediaries, it’s easier to make it yourself, especially since the design itself is simple, you just need to decide on the type of product. Think about where it will be located; most often they are located:

- in the corridor and hallway;

- on the loggia;

- under the stairs (if it is a private house or a two-story apartment);

- in the garage and basement.

The simplest type of rack is two side racks and shelves; this design has no back wall and no side walls. It is preferably placed close to the wall. A more interesting option would be a lattice rack; they can be assembled in different ways, and the shelves can be arranged as convenient for you.Often such products are mounted on the wall using hooks and are considered hanging.

If your home allows, you can arrange shelves under the stairs; this will be an excellent solution to save space, using it as productively as possible. Built-in structures in a niche facilitate the manufacturing process to a minimum, because in this case only shelves will be needed. A ladder rack is a design where the lower shelves are made in the form of drawers-steps, with the help of which you can reach the upper shelves.

If your home allows, you can arrange shelves under the stairs; this will be an excellent solution to save space, using it as productively as possible. Built-in structures in a niche facilitate the manufacturing process to a minimum, because in this case only shelves will be needed. A ladder rack is a design where the lower shelves are made in the form of drawers-steps, with the help of which you can reach the upper shelves.

The mobile rack is equipped with wheels, it is convenient to move and disassemble, it perfectly separates the room into separate zones. As you can see, you can choose the appropriate option, and the material for the construction will be plywood. Such a product will not be very expensive, but very functional.

IMPORTANT! Before you start manufacturing, decide on the size, design and location of the product.

Choosing the size of a plywood shelving unit

Before you get down to business, decide for what purpose the product is intended; its height, depth and width will depend on this. The best thing is if the rack is high, up to the ceiling. Then it can be strengthened with additional hooks.

Cans of preserved food, dishes, books and other similar things have a lot of weight. Shelves for such a load should be made no wider than 25 cm, and their length should be 90 cm. With large parameters for such a weight, the shelves may bend and break.

Cans of preserved food, dishes, books and other similar things have a lot of weight. Shelves for such a load should be made no wider than 25 cm, and their length should be 90 cm. With large parameters for such a weight, the shelves may bend and break.

For light objects, the width of the shelves can reach 50 cm and 150 cm in length. To make it easier to reach objects that are closer to the wall, you should not make shelves wider than 50 cm.

How to make a rack with your own hands: drawing and manufacturing steps

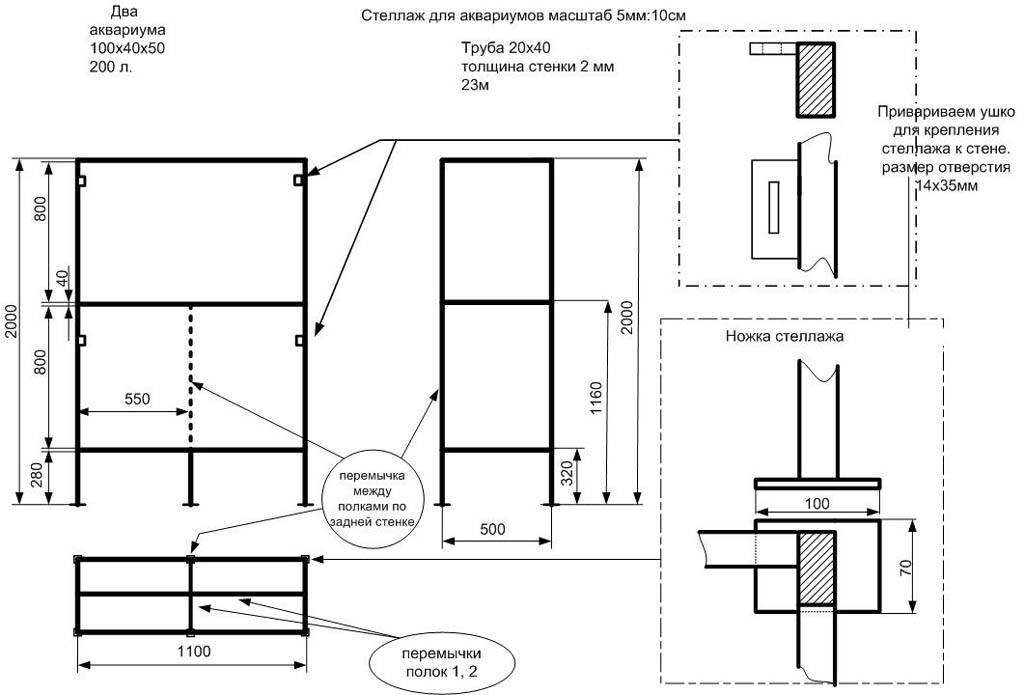

Any design you are going to make will require a basic drawing. A schematic drawing will help you see the end result, so take this stage of the work seriously and try to transfer all your ideas onto paper.

IMPORTANT! Do not forget that the top of the product should be designed taking into account the fact that light objects will be stored on the shelves and heavier ones below. This will help balance the load on the entire structure as a whole.

Sample drawing:

Plywood is one of the most suitable materials for the manufacture of this type of furniture:

- withstands loads well;

- it is convenient to process;

- non-toxic;

- quite light;

- resistant to high humidity.

The entire manufacturing process can be roughly divided into stages:

- drawing preparation;

- preparation of instruments;

- cutting the material;

- grinding;

- installation of the structure.

Preparing tools

Almost everyone in the house has the necessary set of tools to make parts and assemble a structure. At the same time, you don’t have to be a carpenter or joiner, because the tools are the most common:

- plywood;

- shelf holders;

- corners made of metal or plastic;

- screws, drill;

- jigsaw, screws;

- drill, hammer and tape measure.

A mobile shelving unit may require wheels.

Creation of rack elements and its installation

The structure must be strong to withstand the load, so make an appropriate base from a thick board. Its length should be equal to the length of the rack. The step between the bars should not exceed 60 cm.

- Use self-tapping screws as fastenings and reinforce the coal with strips.

- If the structure will have side walls, cut them out of plywood.

- Make grooves for the shelves.

- The thickness of the shelves should be at least 2.5 cm. Install them, securing them with self-tapping screws.

- Place the finished rack on the surface and secure it.

IMPORTANT! When assembling the product, use a level to avoid distortions.

The finished product is varnished and decorated to your taste. You can create such a seemingly complex piece of furniture with your own hands using simple plywood.