DIY timber rack

Of course, most people always want to save money on something. And the way out of this situation can most often be the creation of a homemade structure. This is explained by the fact that independent construction of simple structures is within the power of every person. The process itself does not take much time and raw materials. Usually all that is required is enthusiasm and a small number of tools, and most importantly, desire.

The content of the article

How to make a rack from timber with your own hands

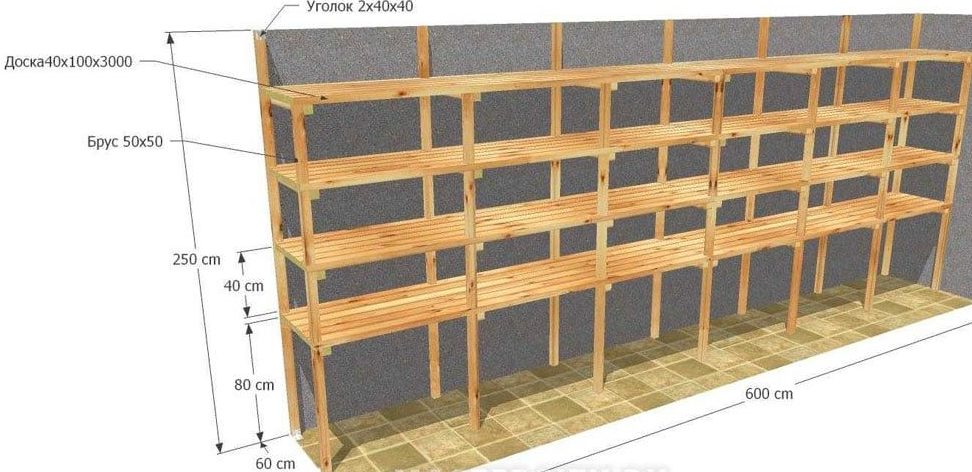

To begin the most basic stage - making a rack made of timber with your own hands, you need to carefully prepare for it. It includes both processing of materials and drawing up drawings. Moreover, the first of them must be taken as seriously as possible.

ATTENTION! The fact that you select such reliable sources for use will depend not only on the period of further operation, but also on the practicality and reliability of the entire device. The entire algorithm begins with drawing up a diagram according to which all further actions take place.

The marking is carried out from the level mark on the sides; it is along them that the shelves will be placed. For the sides you should use natural wood or sheets of plywood. When choosing boards, you should give preference to those whose thickness corresponds to parameters greater than 25 millimeters. If you want to further strengthen the structure, it is better to attach cross bars.

The marking is carried out from the level mark on the sides; it is along them that the shelves will be placed. For the sides you should use natural wood or sheets of plywood. When choosing boards, you should give preference to those whose thickness corresponds to parameters greater than 25 millimeters. If you want to further strengthen the structure, it is better to attach cross bars.

What you will need

As for the tools themselves, there is a list consisting of the following elements:

- Drill.

- Grinding machine.

- Sandpaper.

- Hammer.

- Building level.

- Brackets.

- Electric jigsaw.

- Pencil.

- Measuring tape.

Materials you will definitely need:

- Wooden beams.

- Plywood board.

- Screws and metal corners.

- Construction adhesive, optional.

- Legs for support.

Assembling the rack

Each master chooses his own convenient method for fastening all products. However, most often you can replace the use of nails, screws or metal corners. The entire assembly consists of connecting the back wall to the base using separate parts. Next, the sides are installed. Then, based on the preliminary markings, the brackets are attached. They are needed so that the shelves can be firmly fixed. But for those who do not have such fastening, you can resort to using self-tapping screws. With their help, the sidewalls are fastened to the base. This can certainly guarantee the reliability of the entire invention.

Each master chooses his own convenient method for fastening all products. However, most often you can replace the use of nails, screws or metal corners. The entire assembly consists of connecting the back wall to the base using separate parts. Next, the sides are installed. Then, based on the preliminary markings, the brackets are attached. They are needed so that the shelves can be firmly fixed. But for those who do not have such fastening, you can resort to using self-tapping screws. With their help, the sidewalls are fastened to the base. This can certainly guarantee the reliability of the entire invention.

REFERENCE! To avoid inaccuracies, it is recommended to use a level.

Shelves made of timber

Shelves made of bars are very reliable. The product itself from which the structure is made is best plastered first. This can greatly simplify the entire process.

Using a jigsaw you need to create the required size of shelves. If you are going to save as much as possible on material, then you can fold the parts at intervals. This design will look like a lattice. After laying all the pieces, you need to fix the entire device with a special construction glue.After this stage, it is recommended to further sand the structure using sandpaper. The final stage is coating with a shiny wood varnish. This will finally give your shelving an acceptable appearance. In addition, thanks to this type of fixation, the material will be maximally protected from external irritants, which will certainly affect the long-term use of the unit. The most advanced craftsmen can paint on top of the invention, this will serve as an additional color. The main thing is to comply with the existing interior.

Using a jigsaw you need to create the required size of shelves. If you are going to save as much as possible on material, then you can fold the parts at intervals. This design will look like a lattice. After laying all the pieces, you need to fix the entire device with a special construction glue.After this stage, it is recommended to further sand the structure using sandpaper. The final stage is coating with a shiny wood varnish. This will finally give your shelving an acceptable appearance. In addition, thanks to this type of fixation, the material will be maximally protected from external irritants, which will certainly affect the long-term use of the unit. The most advanced craftsmen can paint on top of the invention, this will serve as an additional color. The main thing is to comply with the existing interior.