DIY wheel rack

Every motorist has to face the problem of storing a replacement set of wheels, depending on a particular season. The shape and size of tires require a convenient place, even for temporary placement. Purchasing a special rack will entail unforeseen expenses, and considerable ones. But making shelves for wheels with your own hands will solve this issue without resorting to big waste.

Every motorist has to face the problem of storing a replacement set of wheels, depending on a particular season. The shape and size of tires require a convenient place, even for temporary placement. Purchasing a special rack will entail unforeseen expenses, and considerable ones. But making shelves for wheels with your own hands will solve this issue without resorting to big waste.

The content of the article

What can you make a rack for storing wheels from?

The raw materials from which the shelves are made must be durable and able to withstand the weight of tires and rims. Based on the type of materials used, the racks are distinguished:

- metal;

- wooden;

- combined.

After putting things in order in the garage, you can find unclaimed blocks of wood or long-abandoned metal profiles that are used to make shelves. If there are none, you need to select and purchase the desired material.

After putting things in order in the garage, you can find unclaimed blocks of wood or long-abandoned metal profiles that are used to make shelves. If there are none, you need to select and purchase the desired material.

ATTENTION! Tires and rims are heavy, so the material chosen must be strong enough to accommodate the maximum amount of rubber on the shelf.

Possible drawings of racks for wheels

Storage products are distinguished by type of design:

- floor;

- wall;

- hanging.

For vertical placement of tires, frame racks are used, and tires with rims are laid horizontally on shelves.

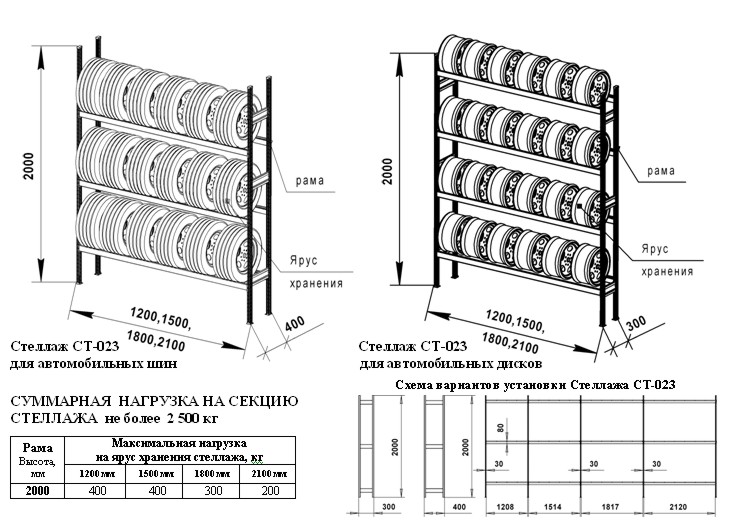

Before making any design, even a very simple one, a sketch is made. The rack is designed for vertical storage of tires without rims. The drawing includes the dimensions of the product, as well as the distance between the individual frame elements. Takes into account the radius of the wheels that will be stored - this affects the size of the transverse beams connecting the vertical posts. The sketch reflects the number and length of longitudinal slats, depending on the number of intended products that will be stored on the rack.

REFERENCE! The standard executive dimensions are considered to be a height of 2 m and a width of 1.5 m. But if the room conditions or user requirements do not allow these values to be observed, then this is not a violation of the design, but only individual characteristics.

Drawings of shelves for wheels

When designing a temporary horizontal arrangement of tires, the sketch provides for such a width that will allow the rubber to lie firmly on the surface. This storage method is used for tires with rims. The height between the shelves is made larger than the width of the wheels that will be stacked on it, while the number of stacked products is recommended to be no more than two.The dimensions of the structure must be larger than the tire parameters and allow free use of the internal space for storing tires.

When designing a temporary horizontal arrangement of tires, the sketch provides for such a width that will allow the rubber to lie firmly on the surface. This storage method is used for tires with rims. The height between the shelves is made larger than the width of the wheels that will be stacked on it, while the number of stacked products is recommended to be no more than two.The dimensions of the structure must be larger than the tire parameters and allow free use of the internal space for storing tires.

Metal rack for vertical storage of wheels

The reliability and durability of metal structures is higher than wooden ones. The use of metal and its profiles will allow you to make a practical tire rack.

What materials will you need?

Before starting work, prepare the following materials:

Before starting work, prepare the following materials:

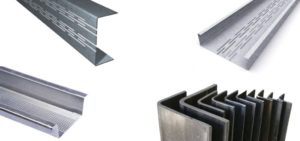

- corner size 35–50 mm;

- profile pipe of rectangular cross-section, say 40x15 mm or similar;

- To ensure rigidity, additional spacers from a profile strip with a width of 35–50 mm are used.

If you do not have a welding machine, you will need mounting bolts with nuts and washers. The threads must withstand the load, so it is recommended to use the M8 connection size.

ATTENTION! For ease of making connections, the rectangular pipe is selected in such a way that one side corresponds in size to the size of the corner.

Prepare the necessary tools

To assemble the required structure you will need:

To assemble the required structure you will need:

- grinder with cutting discs;

- screwdriver;

- measuring and marking tools;

- welding machine with electrodes;

- drill;

- hammer and plumbing kit.

Preparing the components of the rack

Before starting assembly, the material is cut into blanks that will be used in the manufacture of the rack. Depending on the required dimensions of the product indicated in the drawing, corners and rectangular pipes are cut into sections used as racks, longitudinal rails and stiffening crossbars. For ease of installation, the workpieces are laid out depending on the difference in size.

Assembling a rack with your own hands

After preparing the material, they begin to assemble the structure.

After preparing the material, they begin to assemble the structure.

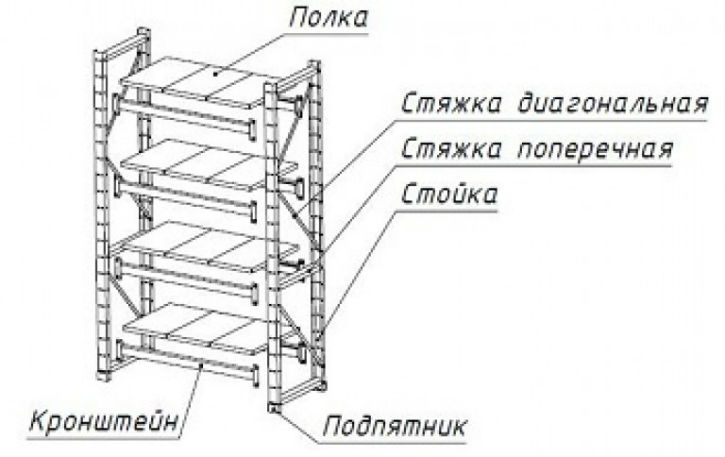

- First, the joints of the parts are marked and the side posts are welded. The vertical supports are made from a corner, and the crossbars are made from a rectangular profile pipe. If the shelves are hanging, then the racks will have a trapezoid shape, and for a regular floor rack, they look like a ladder with a small number of steps.

- At the designed height, the longitudinal slats are welded first to one rack and then to the other. The material of the shared supports must be durable, so a corner is used.

IMPORTANT! The tires will rest on the longitudinal rail. To avoid deformation of the rubber, it is recommended to turn the corner so that the wheels touch the flat surface of the profile. Or use a round profile for longitudinal supports.

- The presence of a large length or height may compromise the rigidity of the product under load. To prevent this from happening, the structure is reinforced with diagonal or transverse stripes, which will not interfere with the placement of tires.

- When the finished structure is placed on the floor, metal “nickels” are welded under the support posts. Such supporting planes will not allow the rack to sag when fully loaded with wheels. Wall mounting will require mounting on hooks or using brackets with dowels.

Before installing the product in the required location, the metal surface is primed several times and then coated with paint.

Rack for horizontal storage of wheels

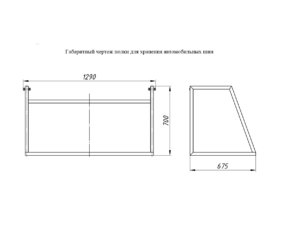

Tires that are not separated from the rims can be stored horizontally.The manufacture of shelves for such placement is distinguished by the possibility of using sheet material as a raw material and a smaller height, which is especially important in limited space.

Tires that are not separated from the rims can be stored horizontally.The manufacture of shelves for such placement is distinguished by the possibility of using sheet material as a raw material and a smaller height, which is especially important in limited space.

The sequence of work is similar to assembling the rack. The difference is that the longitudinal slats are replaced with sheet material, and the height between the shelves corresponds to the width of one or two wheels, depending on the design solution. To save space, such products are often wall-mounted or hanging.

Do-it-yourself wheel rack for the garage

Storing one set of tires does not require the manufacture of a standard rack that can accommodate several dozen tires. Depending on the individual characteristics of changing wheels (with or without disks), the consumer allocates space inside the garage. Considering the small size of the buildings that car owners have to use, it is recommended to install a shelf or wall-mounted rack.

Storing one set of tires does not require the manufacture of a standard rack that can accommodate several dozen tires. Depending on the individual characteristics of changing wheels (with or without disks), the consumer allocates space inside the garage. Considering the small size of the buildings that car owners have to use, it is recommended to install a shelf or wall-mounted rack.

The raw material can be used timber or an unclaimed metal profile that can be found in the garage. The shelf material can be combined, for example, the side posts are made of iron, and the longitudinal slats are made of wood, or vice versa. In the absence of welding skills, as well as for connecting iron products with beams, bolted connections are used.

The raw material can be used timber or an unclaimed metal profile that can be found in the garage. The shelf material can be combined, for example, the side posts are made of iron, and the longitudinal slats are made of wood, or vice versa. In the absence of welding skills, as well as for connecting iron products with beams, bolted connections are used.

ATTENTION! Before using wooden elements to make a frame structure, you must make sure that they have retained their strength properties and treat them with an antiseptic.

Using a self-made rubber storage rack will bring the car owner not only cost savings, but also moral satisfaction, thanks to the opportunity to contemplate his own product.