DIY icon shelf

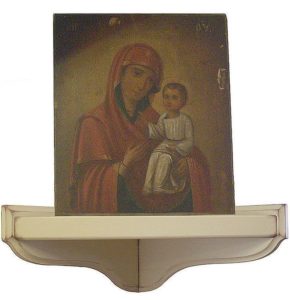

Every person tries to make their room or hallway more comfortable. Especially if you are a believer, you have probably wondered where to store sacred icons. Of course, you can purchase a ready-made shelf, but if you want to make it in your own style, then you have come to the right place. For such cases, there are many ways to manually construct shelves that anyone can do. In this article we will analyze the manufacture of some types of shelves, describe the execution sequence step by step and discuss several options for attaching them to the wall. Before than withmake a shelf For icons with your own hands, you need to draw drawings or find photo on the Internet.

Every person tries to make their room or hallway more comfortable. Especially if you are a believer, you have probably wondered where to store sacred icons. Of course, you can purchase a ready-made shelf, but if you want to make it in your own style, then you have come to the right place. For such cases, there are many ways to manually construct shelves that anyone can do. In this article we will analyze the manufacture of some types of shelves, describe the execution sequence step by step and discuss several options for attaching them to the wall. Before than withmake a shelf For icons with your own hands, you need to draw drawings or find photo on the Internet.

The content of the article

Possible design options

In fact, the variation of stands is quite large. Compared to other shelves, in this case the main component is the placement of only icons on it and no foreign objects. For clergy this is considered a home holy monastery. A do-it-yourself icon shelf should be of the following format: all frames should be visible, so the location of each of them should not overlap the others. It is also necessary to determine free space for new icons, so that in the future there will be somewhere to place them.Or choose a form in which it would be possible to attach an additional platform.

There are several ways to construct stands:

- Straight multi-tiered.

- Corner multi-tiered.

- Straight single-tier.

- Corner single-tier.

The shelf is designed in accordance with the interior, location and size of the room.

Required materials and tools

There are no special restrictions on the use of the material. In addition to wood, metal or plastic can be used. But most often they use wood materials due to ease of processing, quality and relatively inexpensive price.

To create a stand you will need the following tools:

- roulette.

- wood hacksaw or jigsaw.

- screwdriver with drills.

- hammer.

- screwdriver.

Tools required for construction:

- Oak boards or similar in strength.

- Chipboard or OSB plywood.

- Wood glue.

- Steel corners and hinges for wall mounting.

- Screws and dowels.

- Plugs for screw heads.

- Varnish to preserve the quality of wood.

- Slats 20–40 mm wide.

- Sandpaper.

Decoration options

The choice of decor is determined in accordance with your tastes or interior. In order for your shelf to look beautiful and harmonious along with the icons, you can use different methods of decoration:

- wax coating;

- stain of various colors;

- artistic carving;

- patterned burning or engraving;

- varnishing;

- wood painting, etc.

It is not recommended to use a large amount of decor, as it can overshadow the icons.

Manufacturing of parts

The shelf design includes several parts. Most often, the stand is made from the following parts:

- racks;

- side panels;

- shelves;

- legs (if the shelf is not wall-mounted);

- sides.

There are quite a large number of shelves with complex designs. The choice of the size of each part depends on the number of icons, the location of the shelf itself and the shape of the parts.

Straight single-tier shelving

Before manufacturing, it is necessary to think through all the nuances, prepare materials and prepare a drawing of all the details. Once the drawing is drawn, it can be transferred to MDF or chipboard, and templates can be cut out of them.

Before manufacturing, it is necessary to think through all the nuances, prepare materials and prepare a drawing of all the details. Once the drawing is drawn, it can be transferred to MDF or chipboard, and templates can be cut out of them.- The templates need to be transferred to the material from which all the parts will be made (oak boards or any other). You should cut out carefully to avoid damaging the template and the future part. For this it is better to use an electric jigsaw.

- After cutting out the parts, their edges are rubbed with sandpaper and smoothed over with a milling cutter.

- To connect each part, you can use the mosaic connection method. First of all, holes are cut out in a pre-prepared place on the side panel - nests for the shelf platform. At the platform, rods for insertion are cut out. Fastening occurs by connecting the platform rods with the holes in the side panels. For higher strength, use glue for fastening. The second method of fastening is screwing in screws. To do this, platforms (if there are several of them) are installed below and in the middle (or to choose from). Holes are drilled through the sides of the panels, after which screws are screwed in. To make the screws invisible, plugs are attached to them.

- After connecting all the parts, metal loops are attached to the upper edges of the panel.

- Holes are drilled in the wall for the mounting bolts on which the shelf will be hung. It is necessary to take into account the weight of the shelf with icons so that the dowels do not break off at any moment.

- After fastening is completed, the product is treated with protective agents - varnish and/or stain. Colors are chosen in accordance with the interior or at your discretion.

Corner shelf

Most often, corner shelves are planned on 2 or 3 tiers. The basis for this manufacturing option will be fiberboard material. To make a stand you need:

- A right triangle is drawn on a sheet of fiberboard using a pencil or marker. To make calculations easier, you can take sizes 280/280/380.

The drawn figure is cut out with a wood saw or an electric jigsaw.

The drawn figure is cut out with a wood saw or an electric jigsaw.- After cutting, all parts are sanded with sandpaper.

- Having made all the parts smooth, they need to be connected to each other. This can be done using screws or wood glue.

- To prevent deterioration in quality and dampness, the entire structure must be varnished. Decorative patterns are cut out before varnishing.

- Metal loops are attached to the upper corners of the walls.

- In the corner part at a given level, holes are drilled in the wall for attaching hinges.

- The corner shelf is attached to a dowel, having previously calculated the maximum weight in order to avoid falling off the hinges.

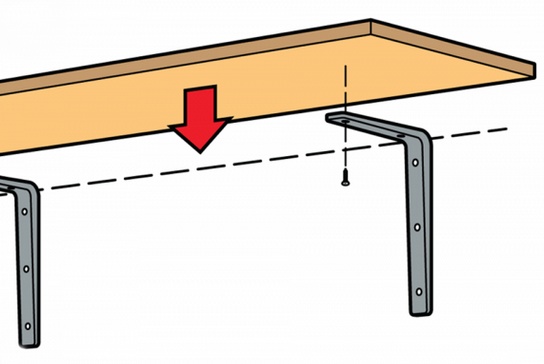

Mounting options

Mounting shelves can be done in several ways. The first one is using dowels. To begin with, the hinges are installed on the product, then holes are drilled in the wall. In this case, you need to choose the right height, preferably at least 1.7 meters from the floor. After determining the height, the shelf is attached to the wall using dowels. This method is the most common, as it does not require much effort and is quite practical.

You can also use brackets for mounting. A bracket is a part or structure used for vertical or horizontal mounting. They are different and depend on the type of fastening. There are brackets for mounting structures; simple single-tier shelves are usually installed on them; and brackets for hanging mounting - used not only for installing shelves, but also for mounting many devices and equipment.