DIY rack made of wood

It is impossible to imagine a modern house or apartment without shelving, they have become so indispensable. They can be found in office spaces and retail spaces. The rack is universal in its purpose; it can be found in the living room or children's room, as well as in the bathroom, corridor, balcony, basement, garage. It all depends on its purpose and the style of your home.

The content of the article

Wooden shelving - features

The most widespread are wooden racks of various designs and structures. The reasons are in their features:

- can be a room decoration;

- save space well - relevant for small apartments;

- can be used when zoning a room;

- have a simple design - you can make it yourself;

- spacious - you can place a large number of books, children's toys, cosmetics and much more.

We make a wooden rack with our own hands

In stores you can buy racks and shelves of various designs and sizes; you can buy them in parts as you receive funds, but if you add everything up you get a pretty substantial amount.If you take a closer look at the finished wooden shelving in a store, you will find that its dimensions do not match your space, or the depth of the shelves is insufficient, or the shelving is not strong enough to store heavy items, or it is quite high, and the price of the shelving is quite high. Taking a closer look at the rack, it turns out that there is nothing complicated in their design. Vertical bars are attached to horizontal bars on which the shelves are located.

In stores you can buy racks and shelves of various designs and sizes; you can buy them in parts as you receive funds, but if you add everything up you get a pretty substantial amount.If you take a closer look at the finished wooden shelving in a store, you will find that its dimensions do not match your space, or the depth of the shelves is insufficient, or the shelving is not strong enough to store heavy items, or it is quite high, and the price of the shelving is quite high. Taking a closer look at the rack, it turns out that there is nothing complicated in their design. Vertical bars are attached to horizontal bars on which the shelves are located.

A hand-made wooden rack can be the pride of a craftsman if it has a beautiful appearance and fits well into the interior. After all, it is carried out by the master according to his sketch, according to the required dimensions, and his unique design.

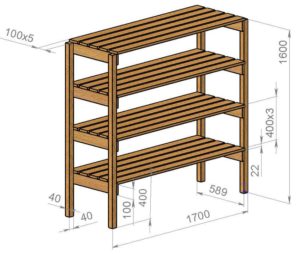

If you have basic knowledge of a school drawing course, you can draw and design a shelving unit, or you can use ideas from specialized literature or the Internet and look at photos. There are numerous drawings and diagrams available for every taste. All that remains is to choose.

Necessary materials

To make a rack with your own hands, you need to take care of the material. The main condition that must be strictly met is that the material is well dried to avoid mold damage, cracking and deformation. The material must have an even outer layer, without distortion. Depending on the purpose of the rack, different materials are used:

- plywood - for carved and small shelves;

- Fiberboard, chipboard and laminated chipboard are durable, easily bendable materials - therefore suitable for modular round and round shelves, widely used by designers for original interiors.

- relief board (with knots, cracks of various shapes) - for shelves of unusual shape;

- soft wood boards: pine, larch, cedar, spruce, alder, linden, aspen - for inexperienced craftsmen.

REFERENCE. If the product is made of coniferous trees, you need to remember about special processing so that the resin does not protrude.

Step-by-step instruction

Just like any task is carried out according to instructions, to make a high-quality and beautiful rack you need step-by-step instructions:

decide on the location of the future rack;

decide on the location of the future rack;- take measurements;

- draw or select a sketch of it;

- draw a drawing according to the dimensions of the selected location;

- calculate the amount of materials required for the product - calculate the total cost;

- purchase the necessary materials;

- prepare tools;

- cut blanks;

- assemble a rack;

- paint (varnish, paint, stain, wax).

The rack is ready. You just need it to dry well and you can use it.

IMPORTANT. When choosing material in a store, pay attention and check for cracks, knots and straightness. Cracks worsen the appearance. Knots are a potential break point.

Types of wooden shelves

Wooden shelves can be made with your own hands, and they can be:

- simple;

- combined (modular);

- removable;

- standard;

- open;

- closed - having doors;

- non-standard.

Racks (shelves) can be classified according to the method of fastening:

- mounted;

- hanging;

- stationary.

They are mounted on the wall and save space. Suitable for small apartments.

- floor racks (shelves) – installed on the floor.

More by location:

- corner – located in the corners, uses corner space;

- built-in - located in various niches.

Non-standard solutions

Shelves are very easy to make, so very often craftsmen apply various design techniques to them. These shelves are beautiful and original:

Floor shelves are transformable. Very simple, compact and versatile, they increase living space in apartments. They can easily take on different forms, change appearance, but continue to perform their main function;

Floor shelves are transformable. Very simple, compact and versatile, they increase living space in apartments. They can easily take on different forms, change appearance, but continue to perform their main function;- Mounted - honeycomb. The shelf, made in the shape of a honeycomb, is original and functional;

- Hanging - suspended from the wall using decorative ropes, chains, belts. In this case, the shelf also acts as a decorative element, decorating the room;

- Luminous - made from non-standard boards with cracks of various sizes and knots. During manufacturing, it is well sanded, and cracks and irregularities are filled with polyester resin. It can also be a room decoration if you add various decorative elements to the resin: luminous paint, glitter, colored stones and even LED lamps;

- Inverted shelf - uses both the top and bottom surfaces. An elastic band of the required size and quantity attached to the bottom surface with a furniture stapler secures the books.

Carved shelves

Carved shelves can be either wall-mounted, corner, standard, or modular (curly wall shelves, antique-style). They are decorated with various carvings and can be an art object. Therefore, in addition to their main purpose, they are an interior decoration and preference is given to rooms with a small area.

Carved shelves are easier to make from plywood. Using a jigsaw, it is easy to cut out a pattern from it; it turns out light, airy and openwork. They can be internal or external, depending on the angle they are intended for.Any option is very original and allows you to use corners productively. Their sizes depend on the expected load. For books and heavy souvenirs, choose a shelf made of 25–30 mm wood, without knots or cracks. The mounting methods also depend on the load. Brackets are considered the most reliable; hinges are less reliable.

How to make a wooden shelf with your own hands

Shelves can be made in horizontal and vertical positions. You can make them yourself if you know how to hold a hacksaw in your hands and know how to use a screwdriver. At the end of the work, you can enjoy the results of your labor. Get another hands-on experience in furniture making.

Required materials and tools

A very interesting and functional modular shelf in the shape of a honeycomb. The modules have a hexagonal shape. Its shape depends on the number of modules. To make it you will need a standard set of tools and materials:

- hacksaw or jigsaw;

- screwdriver (screwdriver);

- construction level;

- roulette;

- screws, dowels;

- miter box;

- file;

- sandpaper;

- wooden plank;

- paint, varnish;

- brush;

- fastening loops.

Step-by-step instruction

Manufacturing stages:

- Draw a sketch of the future shelf.

Take measurements of the place where it will be placed.

Take measurements of the place where it will be placed.- Calculating the weight of items to be placed will help determine the choice of material.

- Make a drawing of the module indicating the dimensions - it will help to calculate the financial costs and volume of material.

- Purchase the necessary material and prepare the tools.

- Treat the board (plane, sand, paint).

- Mark the boards according to the dimensions of the drawing.

- Cut blanks from the board to size.

- File the edges of the workpieces using a miter box, on both sides, at an angle of 300.

- Assemble the modules using self-tapping screws and a screwdriver

- Assemble the modules according to the sketch - massive modules are connected to each other with 3-4 self-tapping screws for strength. For additional strength, partitions can be made in the honeycombs.

- Attach hinges to the back of the shelf using self-tapping screws. The number of fixation points will depend on the length of the shelf. The longer it is, the more attachment points there are.

- Drill holes on the wall for wall mounting or use dowels. The holes are made strictly horizontally using a building level.

- Place the finished structure on the wall.

IMPORTANT. Make shelves for heavy objects as reliable as possible, made of solid materials and significant thickness.

The work is finished and its result is an original, multifunctional and spacious rack for books and various beautiful objects. Quite durable, fits well into the interior of the room and matches its size. You can confidently be proud of such a rack. A positive result can encourage the master to take on new and promising projects, perhaps more complex.

Shelves and racks are an excellent material for the flight of a craftsman’s creative imagination, so modern shelves are not only a place to store various items, but also a wonderful decorative object that decorates a room and makes it comfortable and cozy for living.