DIY metal rack

One of the popular metal structures that is found both in production and in everyday life is a metal rack.

One of the popular metal structures that is found both in production and in everyday life is a metal rack.

The content of the article

Why you might need a metal rack

Metal racks are most often used to store any items; in production conditions they store tools and equipment; in everyday life they are used to store things, household items, winter preparations, etc.

Metal racks are most often used to store any items; in production conditions they store tools and equipment; in everyday life they are used to store things, household items, winter preparations, etc.

Racks are divided into prefabricated and collapsible. In addition, they are distinguished by their carrying capacity.

Such designs can be purchased at a specialized store or made with your own hands.

Making a metal rack for the cellar

A metal rack is often installed in a cellar; it is used to store preparations for the winter. Quite often, such structures are made non-separable, that is, they are assembled using electric arc welding.

A metal rack is often installed in a cellar; it is used to store preparations for the winter. Quite often, such structures are made non-separable, that is, they are assembled using electric arc welding.

Required tools and materials

To complete this job you will need the following items:

- A sketch, with its help, the amount of material needed is determined.

- To make a homemade rack, an equal angle corner is often used; its dimensions are determined in GOST 8509-93.It so happens that structures of this design use corners with shelf measurements from 25 to 50 mm. However, the size of the corner determines the load-carrying capacity of the shelf.

The dimensions of the structure are determined based on the dimensions of the place where it will be installed.

Let's assume that the length of the rack is two meters, the width of the shelf is within one meter, and the height of the structure is within 1500 mm. By performing simple arithmetic operations you can calculate the number of corners:

Let's assume that the length of the rack is two meters, the width of the shelf is within one meter, and the height of the structure is within 1500 mm. By performing simple arithmetic operations you can calculate the number of corners:

To make one shelf you will need 7 linear meters of corner, this length includes two longitudinal corners and three transverse ones. The finished rack will have 2 shelves and 6 racks. In total, 23 p.m of corner will be required.

To assemble the structure you will need the following set of tools:

- A welding machine, preferably an inverter, these devices differ in the quality of the seam; for welding you can use electrodes of the UONI or MR brand, with a diameter of 3 or 4 mm. Welding can be carried out with a welding current of 160–200 A.

- You can use a welding hammer to remove scale from weld seams. To cut the corner to size, use an angle grinder with a circle diameter of 125 or 180 mm.

- To create shelves, as a rule, planed boards with a thickness of 24–40 mm are used.

IMPORTANT! THE CORNERS ON WHICH BOARDS WILL BE LAYED FOR STORING ITEMS MUST BE INSTALLED SO THAT THE 90 DEGREE CORNERS ARE FACING EACH OTHER. THIS WILL PROVIDE A SPACE FOR LAYING THE BOARDS.

And also, in order to prevent the rack from sinking into the ground, it is necessary to weld square plastic pieces larger than the cross-sectional dimensions of the corner onto the vertical supports that will be in contact with its surface.

And also, in order to prevent the rack from sinking into the ground, it is necessary to weld square plastic pieces larger than the cross-sectional dimensions of the corner onto the vertical supports that will be in contact with its surface.

Of course, all work on assembling the rack must be carried out using a metalwork angle; it is used to check the correct connection of the angles.

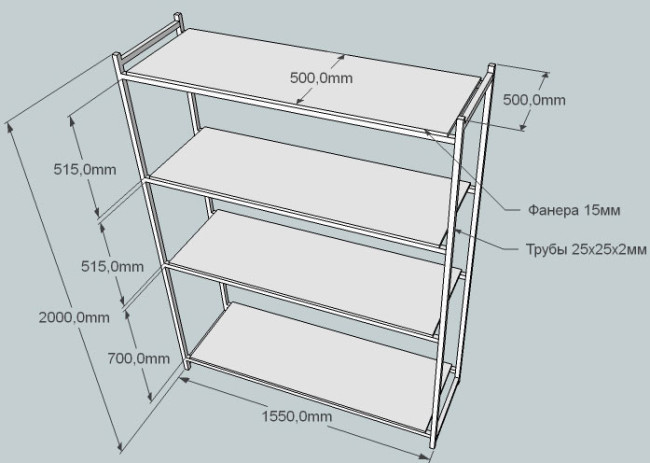

Drawings of metal racks for storing canned goods

Creating working documentation for self-manufacturing a rack will not be difficult. When developing it, it is important to observe all the dimensions that will be required for the manufacture of the structure. Failure to comply with them may result in the assembled product not fitting into its designated place.

Metal rack assembly diagram

The sequence of operations looks approximately as follows.

- First, the shelves are made, and then the racks are attached to them.

- It is not recommended to immediately weld the structure; initially it is assembled using tacks, and only after checking the angles and dimensions can full-fledged seams be made.

How to make a prefabricated metal shelving unit

To make a prefabricated rack, you will need an electric drill, a screwdriver, mounting angles, bolted or self-tapping fasteners and a number of drills. Directly during assembly you will need to use wrenches. It is acceptable to use keys of any type.

To make a prefabricated rack, you will need an electric drill, a screwdriver, mounting angles, bolted or self-tapping fasteners and a number of drills. Directly during assembly you will need to use wrenches. It is acceptable to use keys of any type.

When creating a sketch, it is necessary to determine the connection points of the parts that make up the frame. If bolted fasteners are used, then it is necessary to prepare holes through which the bolts will pass. If the assembly is carried out using self-tapping screws, then there is no need to drill holes. When performing work, it is necessary to constantly use a measuring tool to control the dimensions and joint angles of parts.

Metal shelves for storing canned goods

To store canned products, you can use different materials, wood, metal, polymers.

To store canned products, you can use different materials, wood, metal, polymers.

To make metal shelves, you will need a certain amount of corner and sheet. The corner will be needed to make brackets for attaching the finished shelf to the wall. The width of the sheet for the shelf can be within 300 mm, the length can be within 600 mm. Electric arc welding is used to assemble the structure.