DIY wooden bed

Now you can buy any bed in the store - the assortment is very large. But it is not always possible to choose the right model; the furniture may not be the right size or may not match the design of the room. It happens that the quality of the product leaves much to be desired. Therefore, some craftsmen come to the decision to make a wooden bed with their own hands - the process is not simple, but quite doable.

Now you can buy any bed in the store - the assortment is very large. But it is not always possible to choose the right model; the furniture may not be the right size or may not match the design of the room. It happens that the quality of the product leaves much to be desired. Therefore, some craftsmen come to the decision to make a wooden bed with their own hands - the process is not simple, but quite doable.

The content of the article

Advantages of a wooden bed

The main criterion when choosing ready-made structures is always the material of production, on which the quality of rest and sleep directly depends. The positive aspects of beds made of natural wood are:

- The main thing that can be noted first is excellent external data. Wooden structures look great and beautiful.

- In second place we can put naturalness and environmental friendliness. There are no substances harmful to humans in wood, so there is no need to further process it. In addition, certain conifers emit gentle ethereal vapors that have a beneficial effect on health and well-being.

- Strength and durability. Wooden beds last much longer than structures made from fiberboard and chipboard.

- These pieces of furniture can easily withstand numerous disassemblies without becoming loose or creaking.

- Resistant to deformation and scratches. Even after many years, the appearance of the product will not lose its attractiveness.

- Creates warmth and comfort in the bedroom.

- If you mount a bed from an elite type of wood, the look of the bed will be rich and elegant.

The only downside that can be noted is the high cost of wooden beds.

What is the best material to make a bed from?

To assemble a high-quality and durable structure, it is important to decide on the model that you want to see in your bedroom and select the appropriate material.

From timber

This is the most popular material in the construction market. It combines practicality, beauty and durability. If you pay attention to the sleeping furniture made of timber, which is sold in retail outlets, then it is environmentally friendly, luxurious and practical. Often timber beds are decorated with wood carvings or attractive upholstery - both options look very attractive and rich.

A bed made of this material is often installed in children's bedrooms, since the child spends a lot of time on this structure, for example, a loft bed. This product allows you to place two kids in a small space, or save space when you create a sleeping place on the second floor, and set up a corner for games or activities below.

If you want to build a homemade bed from timber with your own hands, then the easiest option would be to build a podium. But it’s worth mentioning right away that such a design requires a large amount of free space; this is the only way it will look attractive in the overall interior.

From boards

This is also a publicly available material, but you can often find models made from thin, fragile boards on sale. Therefore, many carpenters advise installing the bed themselves, selecting elements of the desired section. In addition, the cost of the design will be much less than a similar store-bought design.

From the array

Solid wood is a material that combines characteristics such as practicality, environmental friendliness, and also looks aesthetically pleasing. This material has a beneficial effect on health, the general atmosphere of the living space and the interior of the room.

At the first stage, you need to select high-quality raw materials of the desired type to make the bed durable, practical and comfortable to use. The most popular are alder, pine, beech, oak, and ash.

Deciding on the model and sizes

The bed is the main, central element of the bedroom. To build a truly high-quality bed, you need to choose the right model. Let's look at the most common options:

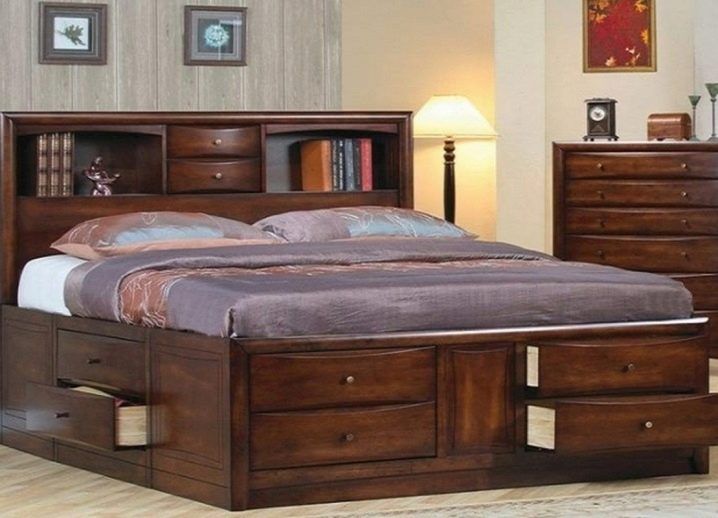

- Double – a bed for a married couple, which occupies the main space in the bedroom. If it is competently made with your own hands from natural wood, it can become a real interior decoration. It can be decorated with various carved elements, or a large, voluminous headboard or canopy can be built.

- Two-tier is a practical model, perfect for small rooms in which saving space comes first. This is an excellent design for a children's room with 2 children.

- With drawers - can be children's, single, one-and-a-half or double. In addition, the type of drawers can be different - retractable, built-in.

Product sizes

To determine the size of the product, the first step is to take into account the height and weight of the person who will constantly use the sleeping place. Of course, all beds have standard parameters for which the purchased mattress is ideally suited. When assembling a structure with your own hands, the mattress is measured first, since the place to sleep will depend on its size.

DIY wooden bed: step by step process

The algorithm for self-assembling a wooden bed is as follows:

- preparation - creating a project for a future bed, purchasing material, cutting it into the necessary elements;

- assembly of all components according to the drawing;

- processing and decoration.

IMPORTANT! For the supporting structure, you should choose durable wood, for example, larch or birch. The slats under the mattress can be pine, but not less than 2 cm thick. For decoration, you can use thin spruce planks - choose high-quality material without knots.

Simple DIY bed

Let's consider making a bed yourself for a standard mattress 90 x 200 for an adult or 80 x 190 for a teenager. Before starting work, prepare the following:

- block 5 x 5 cm - we will form legs from it;

- boards - 2.5 x 24.5 cm for the frame, 2.5 x 10 cm for the floor slats, 2.5 x 20 for the headboard;

- block 2.5 x 5 for supporting elements under the lamellas.

In addition to lumber, you will need:

- bed tie and corners;

- self-tapping screws;

- wooden dowels 80 x 8 mm;

- wood glue;

- finishing material (impregnation, stain and varnish).

To assemble any bed you will need a set of tools:

- drill with drills;

- screwdriver;

- plane;

- hacksaw or small circular saw;

- grinder, with grinding wheel;

- clamps;

- paint brushes;

- level and carpenter's corner;

- miter box - for cutting corners at 45 degrees;

- tape measure or construction meter.

The algorithm of actions is as follows:

- The first step is to assemble the headboard. Cut out 2 legs 80 cm long from 5x5 cm bars from the inside at the top of each element and drill a hole for fasteners, three for each section.

- Prepare two blanks 95 cm long from a 2.5x20 cm board. Make holes at the end that should coincide with those previously drilled on the bars.

- Apply wood glue to the parts that will be in contact, connect and fasten with specially prepared dowels - carefully hammer in with a rubber hammer.

- Now it’s the turn of the footboard, which is assembled from a 2.5x24x95 cm board and two small 40 cm pieces of timber for the legs.

- They should be fastened in the same way as the headboard.

- Then you need to fasten the headboard and footboard with sidewalls made of boards 2.5x25x190 cm. The elements are fastened with ties and furniture corners with alignment along the edges of the legs.

- The support bars are installed along the lower edge of the sidewalls, having previously coated the joints with wood glue. Before removing the clamps, all elements are scrolled with self-tapping screws in increments of 25 cm.

- Make 14 lamellas from a board of the required section, which are screwed to the support bars with self-tapping screws at a distance of 3.5-5 cm.

IMPORTANT! Before assembling all the parts together, they should be sanded and processed. In addition, it is worth checking all elements for horizontal and even angles.

Making a double bed

When assembling this type of bed, you should install an additional jumper along the bed, which will not allow the mattress to sag. In this case, the headboard is assembled from two bars and a wall, which is formed from 2-3 boards 140 cm long, with a cross-section of 2.5 cm. The legs are made from bars. Fastening is done with dowels, wood glue and self-tapping screws.

The footboard is also assembled. The sides are placed at the same level with the lowest boards of the back and footboard. The outer edge of the topmost board needs to be made safe, so the corners are cut off. This can be done using a special tool or using a hand plane.

Making a double bed

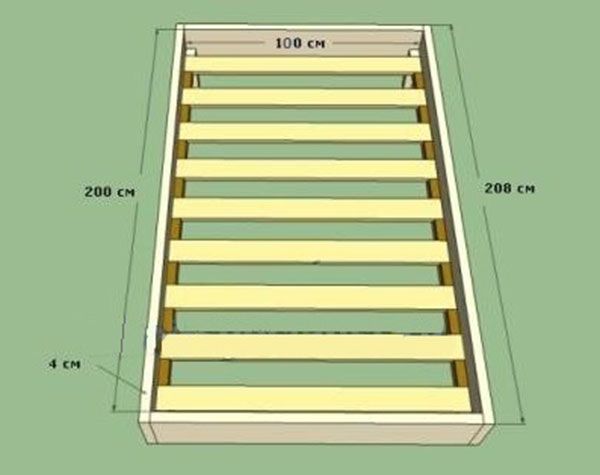

Two people on a bed is a significant weight, so the selection of material must be approached very carefully. It is advisable to make the bed from solid wood. A standard bed for two has dimensions of 2.0 x 1.6 meters.

To do this, prepare the following components:

- block 5x5 cm, for frames and legs, 30x30 mm for supporting elements under the lamellas;

- boards 2x10 cm for flooring under the mattress;

- furniture corner and screws.

The tool is the same as when assembling the first two types of beds.

The algorithm of actions is as follows:

- Assemble a frame with internal parameters for a mattress with a height of at least 20 cm. To do this, several bars are glued together using clamps.

- Then prepare the longitudinal jumper.

- All elements are fastened with wood glue and furniture corners aligned along the edges.

- The legs of a double bed are made of thick timber, from which all sharp corners are cut off.

- To prevent the structure from deforming at the corners, braces or triangular inserts are installed.

- Supporting elements are installed along the lower edge of the sidewalls.

- Slats are prepared from the boards, which are mounted on the support beam using self-tapping screws with a pitch of no more than 3 cm.

IMPORTANT! To prevent the bed from creaking in the area of the slats, they are made 1 cm smaller than the required size - they should not touch the bed frame.

After the assembly is completed, all that remains is to treat all surfaces with sandpaper, cover with stain and varnish.

If you approach the installation correctly, it will not be difficult to assemble any bed with your own hands, just be patient and follow the tips described above.