Do-it-yourself bed with a lifting mechanism

A bed with a lifting mechanism is the best option for small apartments, which solves several issues at once. Firstly, space is saved significantly, and secondly, the bed can serve as a storage box for bed linen or clothes. Making such a mechanism at home with your own hands is quite simple and without unnecessary furniture costs. To get started, just select the right materials, look at the drawings and begin the step-by-step guide.

A bed with a lifting mechanism is the best option for small apartments, which solves several issues at once. Firstly, space is saved significantly, and secondly, the bed can serve as a storage box for bed linen or clothes. Making such a mechanism at home with your own hands is quite simple and without unnecessary furniture costs. To get started, just select the right materials, look at the drawings and begin the step-by-step guide.

The content of the article

Required materials and tools

As in production, to start production you will need to correctly calculate the amount of material, choose the material itself and think about the dimensions. To start making, you will need:

- Chipboard or OSB. Box base. Sheets made from these materials are cheap and easily available. The choice of density and rigidity depends on the wishes of the owner of the future bed.

- Upholstery. The owner can choose the material for upholstery of the box according to his taste and design preference. Foam rubber with a hypoallergenic coating is most often used. This folding bed becomes soft.

- Sheathing. It is recommended to use dense fabric that will not tear during installation (faux leather, velor, etc.).

Basic tools:

- medium size level;

- electric jigsaw;

- welding machine;

- screwdriver with attachments;

- grinder for metal;

- dryer (when using wood varnish).

Attention! It is recommended to cover the bed in separate parts. To make the upholstery soft and elastic, it is recommended to use sheet foam rubber, for installation of which you will need furniture glue and a stapler.

Types of lifting mechanisms on the bed

There are three types of lifting mechanisms:

- Gas. The rise occurs thanks to shock absorbers-springs. Silent and easy to lift mechanism, the box rises without the use of force.

- Mechanical. Lifting occurs thanks to metal springs. The design is easy to install, but the service life is no more than 4 years.

- Manual. The most budget option, there are no problems with installation. Usually used for making adult beds, since in order to tilt the box you need to use manual force.

Important! At home, it is recommended to use gas lifting mechanisms. They are much stronger and more durable, and you can also find budget options in stores.

Drawings and measurements

Calculations are made for the base of a box 1800*2000 with a height of at least 40 cm, so that there is room for a compartment for things.

In total you will need three components, bars, corners and panels.

- bars: 3 pieces with size 50*50*3000;

- shields: 4 pcs with dimensions 18*400*2000 (2x) and 18*2000*1600 (2x);

- mounting angles: 8 pcs with size 50*50*50, and 20 pcs 20*40*20.

During installation, it is necessary to measure the degrees of the angles so that the frame lies evenly and does not creak.

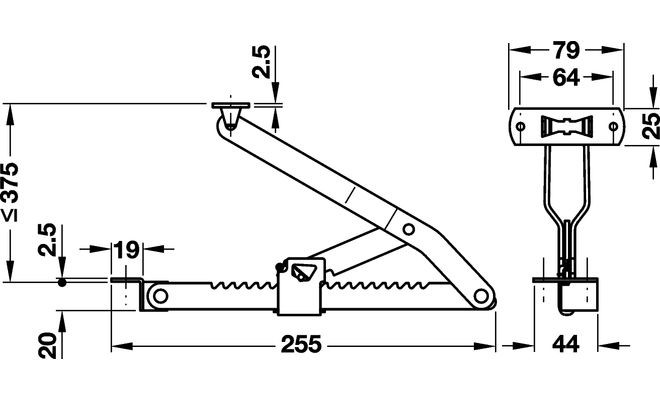

Drawing for a manual mechanism

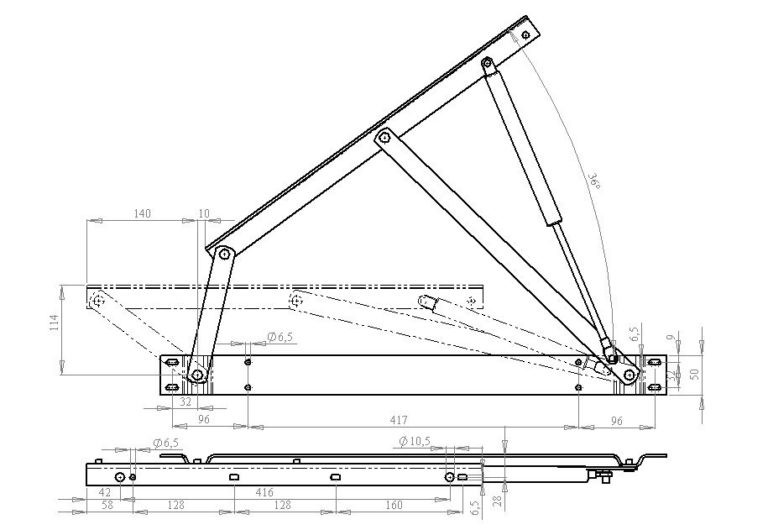

Drawing of a mechanism with shock absorber springs

Important! For installation, drills of 2, 5 and 7 mm with wrenches of 10 and 13 mm are useful.

Bed with a lifting mechanism: step by step

DIY lifting frame:

- Assembling the box and fastening the corners according to the drawings.All work is carried out on the floor to avoid distortions.

- Processing wood coating and gluing corners with glue.

- For large beds, a partition for support is installed parallel to the frame in the middle.

- Inside the box, slats (20*80) are fastened with self-tapping screws and aligned along the bottom of the structure.

- Slats are drilled along the bottom of the frame every 15 cm.

- Processing of the structure begins.

Upgrading and securing the main frame:

- Notches and uneven surfaces are sanded and varnished (if desired).

- A plywood support sheet is laid on the lamellas.

- Metal corners are installed in the corners.

- The slats and bed legs are attached to the corners of the bottom. The screws go through the outside of the frame to keep the bed stable and strong.

- Rubber or a piece of linoleum is glued to the legs to prevent the floor from being scratched.

Important! The spring mechanism carries the load on the frame, so that the bed does not sag, metal bases (slats) are placed on the base parts.

Spring mechanism fastening:

- The fastener is attached to the base of the bed from the base part.

- The lifting of the mechanism is adjusted.

- The support strip is installed on the box.

- Checking the functionality of the entire structure.

For the back you will need a sheet of material from which the frame was made.

Manufacturing:

- The required shape of the back is cut out from a single sheet with a jigsaw.

- A wooden border is attached.

- Then two sheets of foam rubber are glued onto the plywood and you can begin covering.

- For softness, batting is added, from which beds can then be made into various shapes.

- Sheathed with material. The back part along the edges of the bed is fixed with construction glue, and cuts are made on the folds so that the material does not overlap.

- Once the back is completely covered, you can use a stapler to make a shape.

Important: When cutting out a shape, you need to take into account that working with straight shapes is much simpler and easier. If the master does not have special skills, then the cladding may turn out sloppy.

Let's start with the sheathing. The materials for the upholstery of the finished bed are selected according to the personal preferences of the owner; leatherette, dermantin or thick fabric are mainly used.

Attention! For wooden structures, varnishing with wood materials should be carried out before covering in order to increase the life of the bed.

Step by step guide:

- Upholstery of the main frame and back.

- To make the furniture decorative and beautiful, sheet foam rubber is glued along the perimeter of the structure.

- The legs of the bed are covered with construction adhesive and attached to the finished bed.

- You can trim the area around the leg with a construction stapler in two rows. The main condition is that the material must be wrapped so that the appearance is neat.

- The finishing of the lower part is carried out without bending the material.

- After all the parts of the bed have been upholstered, the corners are installed on the inside of the bed.

Before doing the work, you need to understand one thing: the most difficult thing in making a bed with a lifting mechanism is the drawings and calculations of the material. To ensure a decent result, it is recommended to watch video tutorials and advice from professionals in advance, who will tell you what the main mistakes are made during home installation. Ultimately, the owner of the stock can be convinced that the result is much better and more reliable than factory models. This is achieved thanks to all geometric and proportional compliance, which everyone selects to suit their needs and financial capabilities.