Do-it-yourself bed made from a profile pipe

The bed is the main element in the bedroom. Wooden products are considered the most popular. Metal beds are not often chosen, since the choice of models is not very large and most of them involve the use of a metal mesh (sleeping on this bed is harmful to the spine). But you can make a comfortable metal bed yourself. This will cost much less than custom-made furniture.

The bed is the main element in the bedroom. Wooden products are considered the most popular. Metal beds are not often chosen, since the choice of models is not very large and most of them involve the use of a metal mesh (sleeping on this bed is harmful to the spine). But you can make a comfortable metal bed yourself. This will cost much less than custom-made furniture.

The content of the article

How to make a bed from a profile pipe

Unlike factory furniture, assembling it yourself has many advantages:

- Manufacturing according to your own drawings allows you to make a bed of any size and shape, taking into account the interior of the room.

- The author's design allows us to produce unique furniture, the analogues of which simply do not exist.

- The final cost, even with all the costs, will be much cheaper, as opposed to purchasing the same item in a store.

- The choice of high-quality materials and a careful approach to the assembly process significantly increase the reliability and service life of finished furniture.

What does that require

Before you start assembling the product yourself, you need to get acquainted with the different models. Determine your own capabilities and likely difficulties in production.Many designs are simple and accessible even to novice craftsmen.

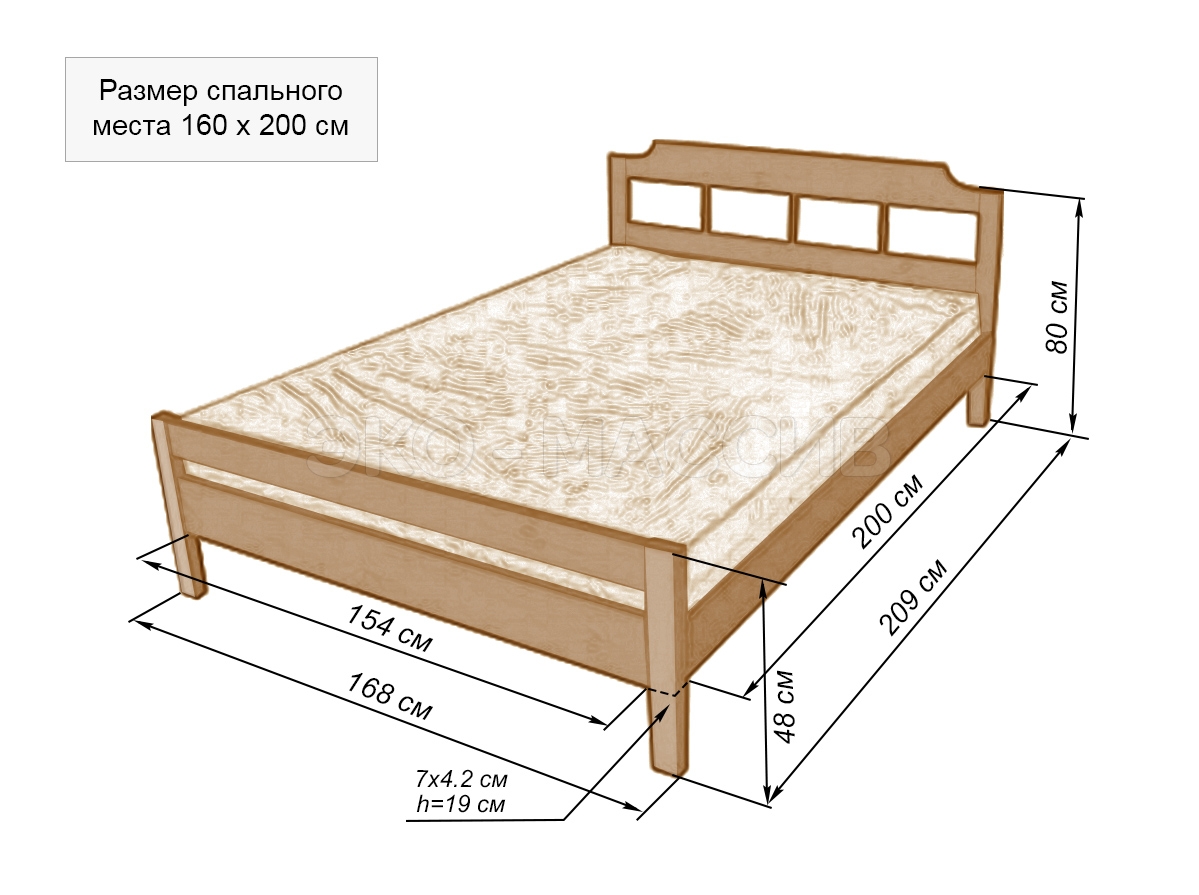

Attention! Then you need to draw up action steps and prepare tools. Determine the size and design of the base, taking into account personal preferences.

Preparatory stages:

- Creating a drawing.

- Preparation of materials.

- Measurements of the dimensions of the mattress, which is best to buy before starting assembly. This way it can be compared with the product during manufacture.

- To assemble a metal bed, welding will be required.

Additional tools:

- Bulgarian;

- ruler;

- electric drill;

- natfel;

- square;

- sandpaper;

- brush;

- primer;

- brush;

- dye.

How to prepare a profile pipe

After creating drawings, calculating overall dimensions, purchasing the required materials, we begin preparation.

Pipes of the required size are cut (taking into account the drawing), they are processed, and additional holes are made. Cutting is done with a grinder, after which all cuts are polished to level the surfaces.

The profile is degreased with acetone. This is required for further painting. The holes are necessary for fixing the pipes using self-tapping screws. Most often, welding and fastening with self-tapping screws are combined.

Possible difficulties during work

The actual process of making a bed is simple. You will need skills in working with an angle grinder and a welding machine. If you don’t have these skills, you can first practice on separate scraps, rehearsing cutting and welding joints.

It’s just that a bed is a three-dimensional structure; assembling its individual elements is not difficult, but connecting them together sometimes creates certain problems. For example, the most difficult stage in the manufacture of a frame is welding the last corner.Moreover, three corners are already fixed, and the frame is quite heavy and bulky.

It may also be difficult to paint the bed. All sides of the product must look aesthetically pleasing. Why is it necessary to either paint each piece of furniture separately, which takes a lot of time, and then dry all the parts and only then assemble them. Or you can paint an already assembled structure, but in this case you will need to protect the slats from paint.

Attention! Beginning craftsmen may encounter a shortage of required parts, lack of necessary tools, or incorrectly calculated sizes of various bed elements. For example, if you cut a pipe smaller than necessary, then the part is already damaged.

Do-it-yourself bed made from a profile pipe: step by step

When the metal is prepared, assembly can begin:

- First, the frame is made. This is a rectangular base, all elements of which are secured with screws and welding.

- Afterwards the legs are welded at the corners.

- Fasteners for the lamellas are fixed on the top of the frame (it is best to buy the fasteners in the store at the same time as the lamellas, this will greatly facilitate the assembly process).

When the frame is assembled, it needs to be painted, and it doesn’t matter whether the decoration will be made with chipboard in the future or the bed will remain in this form - protecting the metal from corrosion is necessary. It is best to fix the slats in place after painting.

The procedure for painting metal is the same for any part of the structure:

- If the factory grease has not been removed before, it must be removed and the surfaces rinsed thoroughly.

- The washed and dried base is degreased.

- Then the primer is applied.

- When the soil dries, the bed can be painted.If you plan to decorate using chipboard, then you can choose inexpensive paint, but all exposed parts of the product must be painted with high-quality compounds. In addition to high quality, the paint must also be environmentally friendly, since people spend a lot of time sleeping, and toxic substances have a negative impact on health.

- Then you need to wait until the paint dries and insert the slats into the grooves.

A bed made of metal is aesthetically attractive and will fit perfectly into any bedroom. There are many photos of master classes that show the assembly process in detail. And if you have experience and the required tools, the manufacturing process will not be very difficult. A self-assembled metal bed will last a long time and reliably.