DIY metal bed

Creating a metal bed yourself, although a somewhat difficult and technically complex project, is very interesting. To make such a structure, you will need some skills, in particular, at least basic forging or welding skills, patience and time. In addition, special equipment is required. But if you still decide to assemble a bed, then the article below will help you accomplish your plans.

Creating a metal bed yourself, although a somewhat difficult and technically complex project, is very interesting. To make such a structure, you will need some skills, in particular, at least basic forging or welding skills, patience and time. In addition, special equipment is required. But if you still decide to assemble a bed, then the article below will help you accomplish your plans.

The content of the article

Types of metal bed designs

The number of metal bed options on the market can satisfy any request.

Two types of structures can be distinguished:

- Forged. Their base consists entirely of pipes. They are relatively light: the weight is always no more than 50–55 kg. There are two types of forging: cold and hot. In the first case, a person does practically nothing: the machine does everything necessary, so the assembly is vaguely reminiscent of stamping. If we are talking about another method, then the master does the main work. It heats metal products to a temperature of 600 degrees, after which, during forging, it gives the necessary shapes to the parts.

- Welded. The main difference from the previous type is the method of connecting the parts, i.e. welding.

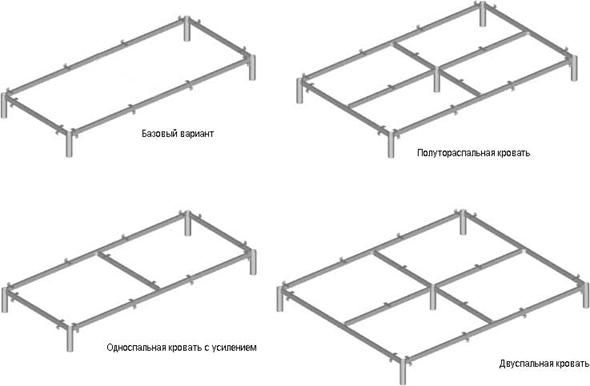

Preparing to make a metal bed: drawings

- create a drawing - we recommend using the options presented on the Internet;

- purchase materials and, if necessary, tools;

- buy a mattress - formally, this item should be number one, because based on the size of the mattress, the future dimensions of the structure are determined.

Tools for work

To make your own iron bed, you will need the following list of tools:

- Welding machine.

- Angle grinder (grinder).

- Drill and several metal drill bits.

- Measuring instruments.

- Brushes for painting.

- Varnish.

As mentioned above, the peculiarity of welded structures lies in the method of fastening the parts. They are connected by welding. If you decide to pay attention to forged varieties of beds, then you will also need blacksmithing equipment. The list changes depending on the style. We recommend consulting with a specialist.

DIY metal bed: step-by-step technology

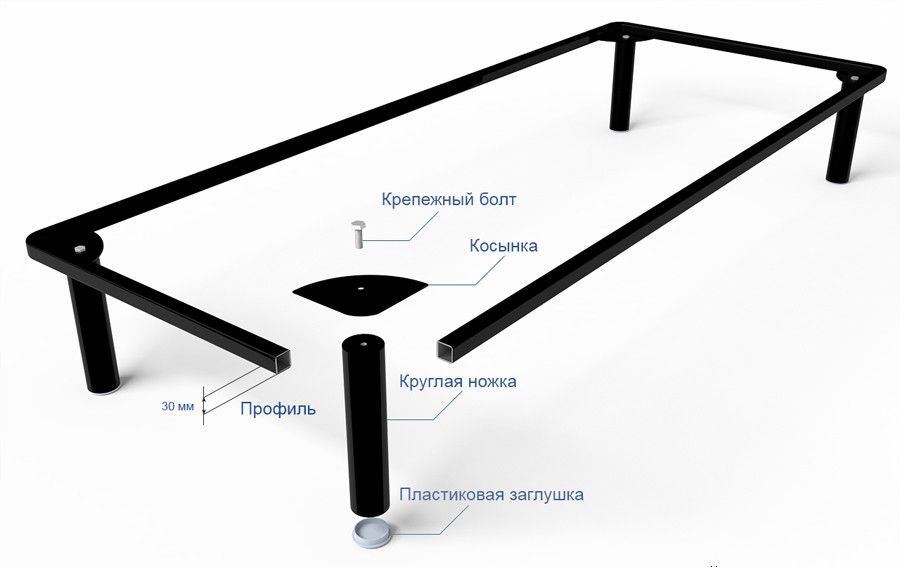

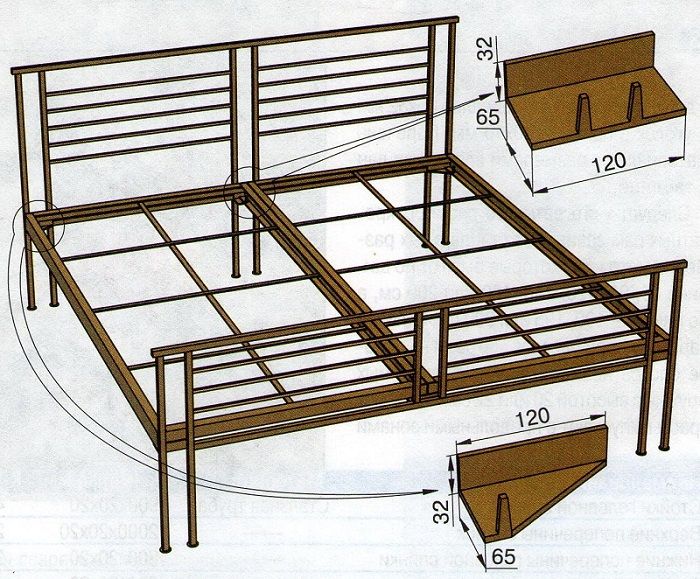

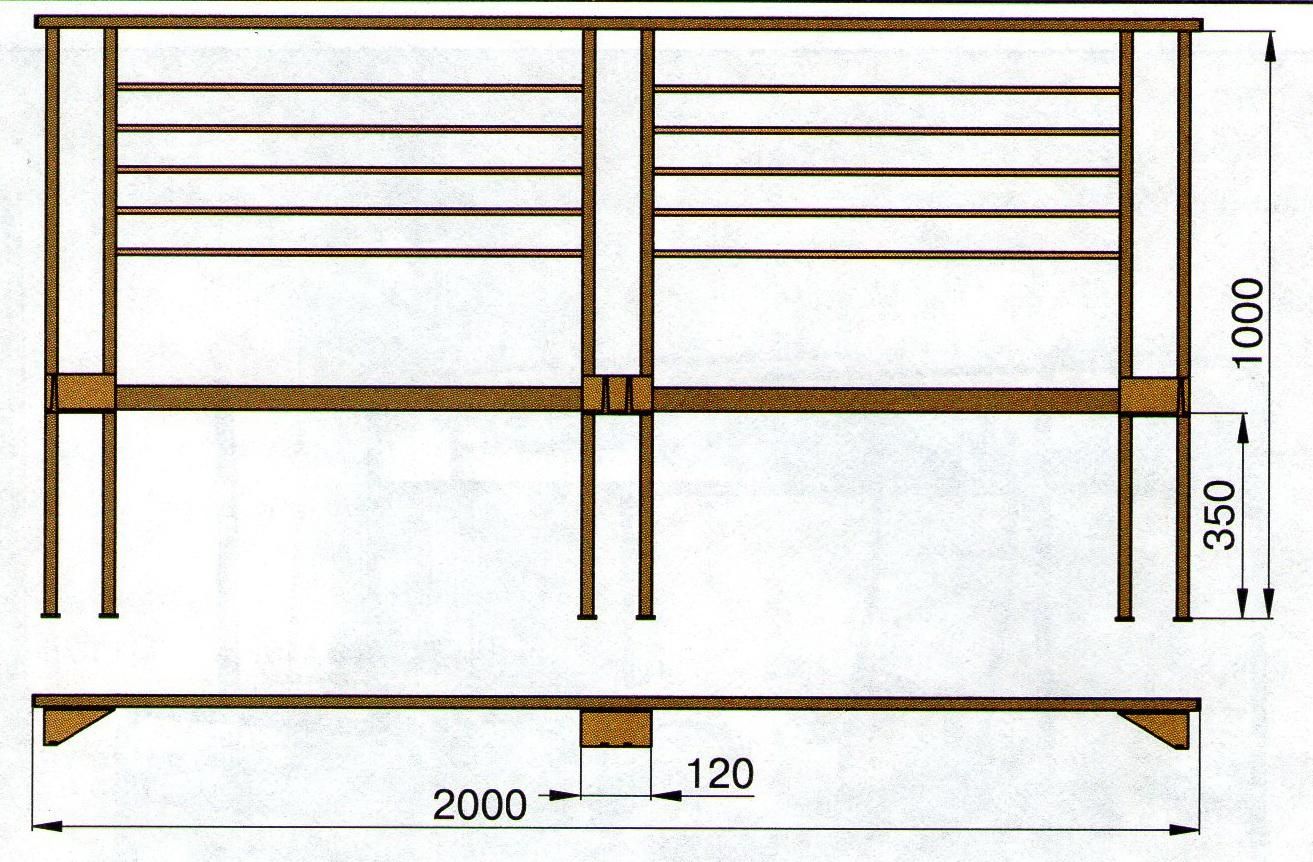

Based on the selected drawing, prepare blanks made from profile pipes - they will become the basis of the future backrest. Lay them out on a level place, in accordance with the diagram, and then secure them with welding. Pay close attention to the degree of the corners if you want to get an even structure. Then the steps and plugs are installed on the ends of the pipes.

Next step. You will need a grinder and a channel. Brackets are created to attach the frame. Again, you should proceed from the drawing, but the following proportion is almost always observed: 2 in the center, 4 on the sides, the slope of the latter should be equal to 5 degrees. Attach the frame to the back with a continuous seam.The accepted distance to the floor is no more than 0.45 m.

IMPORTANT! Channels (preferably made of steel) must be cut into special blanks. The most optimal calculation is: frame length + 4–7 cm. The channels should be connected with corners.

Decorating an iron bed

To give a more pleasant appearance to the created structure, it is necessary to cut off all irregularities, seams, etc. with a grinder, then brush and sand it.