DIY plywood bed

The huge variety of beds presented in furniture stores is amazing, but often the attractive appearance hides not very good quality. When buying furniture, there is no confidence in its durability, unfortunately, since the number of factors influencing this parameter is large, and not every buyer is aware of them. An alternative to expensive furniture of questionable quality is a do-it-yourself plywood bed, which anyone can make.

The huge variety of beds presented in furniture stores is amazing, but often the attractive appearance hides not very good quality. When buying furniture, there is no confidence in its durability, unfortunately, since the number of factors influencing this parameter is large, and not every buyer is aware of them. An alternative to expensive furniture of questionable quality is a do-it-yourself plywood bed, which anyone can make.

The content of the article

Preparing a drawing, materials and tools for assembling a bed

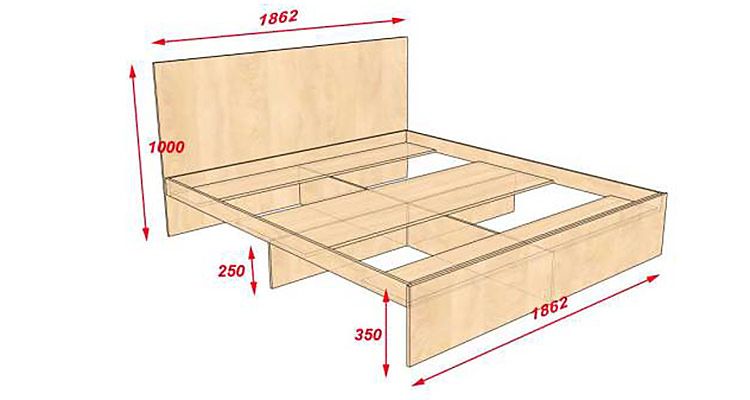

The material used is affordable and easy to process. This makes it easy to give furniture smooth outlines, round corners and cut out decorative patterns. The initial stage is drawing up a drawing of the future bed, indicating all dimensions, places of fastening and finishing. It is recommended to adhere to the standard values of mattresses, which will save you from subsequent searches for non-standard products.

The advantage of making it yourself is that the furniture can be of any size. You can make the drawing yourself or find a suitable one from the many presented on the Internet. Once you have it in your hands, you need to stock up on the following materials:

- high-quality boards with a thickness of more than 40 mm;

- 3 plywood sheets with a thickness of 15 mm;

- ready-made legs, but you can make them yourself from timber.

As for the tool, you will need:

- screwdriver and screws;

- tape measure, pencil and ruler;

- bolts, washers and nuts;

- electric jigsaw;

- sandpaper;

- wood glue;

- paint or varnish.

ATTENTION! It is better to purchase acrylic paints and varnishes, since they are harmless and do not contain solvents. A screwdriver and a jigsaw are not the cheapest tools, but you can save money and borrow them from your friends during the work.

Step-by-step assembly of a plywood bed with your own hands

Plywood is preferred due to its high strength, wear resistance, ease of processing and smoothness. Its cost is also important - the bed will end up being several times cheaper than a purchased one. Of course, it also has a drawback - low resistance to moisture, but in this case it does not matter. The entire manufacturing process consists of several stages:

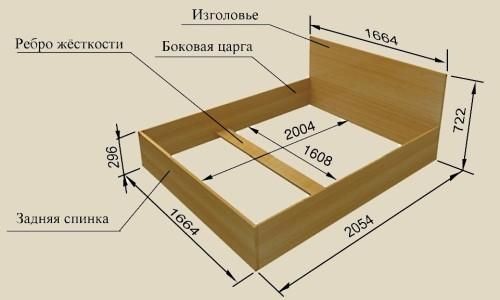

- Frame. First of all, longitudinal ribs are cut out of 18 mm plywood, the height of which is 150 mm. The length of the legs should be 36 mm shorter than the mattress. To determine the amount of material, you need to take into account that two stiffening ribs and sidewalls alternate every 40 cm. The length of the transverse ribs is 5 mm greater than the length of the mattress and there should be only 2 of them - at the edges of the bed. Assembly is carried out end-to-end and fixed with self-tapping screws. They screw into pre-drilled holes of slightly smaller diameter.

- Legs. They are made of timber, and they do not have to be long - 20 cm will be enough.The length can be varied based on personal preferences - it can be either less or more than the specified value.

- Sides and headboard. Sidewalls are overlay elements on the longitudinal ribs of the product, the height of which should be sufficient to prevent the mattress from moving. The edges should be given special attention - carefully sanded and ensure that they are straight. The finished elements are screwed to the outer longitudinal frame ribs, and then with long self-tapping screws to the transverse ones. The headboard should protrude 30–40 cm above the frame. The process of its manufacture and fixation is the same as for the sidewalls.

- Flooring. For it, fragments are cut out of plywood, which in total are equal to the size of the frame, after which they are fastened with self-tapping screws, observing a fixation step of 25 cm.

ATTENTION! All elements cut from plywood should be carefully sanded before assembly.

ZThe final stage is to eliminate all irregularities and roughness with sandpaper and coat the structure with paint or varnish at least 2 times. Throughout all stages, you should constantly monitor compliance with all dimensions indicated in the drawing, especially if you have never encountered this type of work before.

What nuances need to be taken into account

Making a bed from plywood with your own hands is a fascinating and interesting process, on the one hand, but requiring patience and some effort, on the other. Lack of experience may affect the quality of some elements or their assembly, but to avoid this, it is enough to use the recommendations of specialists:

- if the plywood sheets do not have a laminated coating, you should apply paint or stain to them before starting work and allow them to dry completely;

- the headboard should not be made too high, as if you lean on it carelessly, you can break it;

- to hide the screw head, the hole should be slightly enlarged with a drill of a slightly larger diameter;

- when fixing the linings, the fasteners should be screwed symmetrically, since they will always be visible - for this it is recommended to first mark the screwing points with a pencil;

- You can make the bed more stylish and consistent with the design of the room by covering the headboard with fabric or finishing it with foam rubber and covering it with decorative patterns;

- rational use of the free space under the bed is possible with roll-out linen drawers;

- If the room is of modest size, then lifting mechanisms will allow you to save precious square meters.

This design is quite simple, but no one forbids you to change the dimensions at your own discretion, which will add to the attractiveness of the self-made structure. Such furniture is guaranteed to be durable and reliable, it will serve you for many years.