DIY double bed

Making furniture with your own hands is a popular and fashionable trend, because to make your idea a reality there is no need for experience or significant financial costs. In addition, the quality of most products in stores leaves much to be desired, although their cost is unreasonably high. Making a double bed with your own hands is quite possible; it is guaranteed to be strong and durable, and will organically fit into the design of your interior.

The content of the article

Deciding on the design - drawings and diagrams

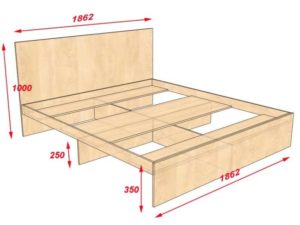

The beginning of the work is the development of a drawing indicating all dimensions, fastening points, finishing, etc., which is typical for the manufacture of any furniture. It can either be developed individually based on your requirements, or taken from many photos presented on the Internet. You should not limit yourself to a simple design - double beds can be high and low, have additional linen drawers, a roll-out mechanism, etc. During the work process, you should constantly check the drawing, monitor the compliance of sizes and the correctness of all steps.

The beginning of the work is the development of a drawing indicating all dimensions, fastening points, finishing, etc., which is typical for the manufacture of any furniture. It can either be developed individually based on your requirements, or taken from many photos presented on the Internet. You should not limit yourself to a simple design - double beds can be high and low, have additional linen drawers, a roll-out mechanism, etc. During the work process, you should constantly check the drawing, monitor the compliance of sizes and the correctness of all steps.

Stages of assembling a double bed

The complexity of making furniture depends entirely on the chosen material, which can be:

- tree.

- metal.

- MDF.

- Chipboard.

When choosing, you should be guided by the design of your interior, but a metal bed will require welding skills. In any case, the wooden product is the simplest and most attractive. To make it you will need less time, money and effort.

We prepare the necessary materials

The next step will be to prepare the required materials and tools based on the size of the future bed. A double bed must be made from quality materials. It is recommended not to neglect the free space under the bottom and equip the bed with a lifting mechanism. For a double design of standard sizes you will need:

- 4 boards for the frame (240x30x2.5);

- 3 boards for decorative finishing (240x5x2.5);

- 3 boards for support beams (240x10x3); 3 boards for decorative finishing (240x5x2.5);

- 1 beam for legs (240x10x10);

- 19 boards for arranging the bottom (240x7.5x2.5).

REFERENCE. When choosing wood, pay attention to its quality. So, for the supporting structure you will need exclusively high-quality material, while for the slats and legs, second-class material is suitable, the cost of which is much lower.

If you decide to equip the bed with a lifting mechanism, you will need a little more material, since you will need to assemble a lifting frame. As for the tool, you need to prepare:

- tape measure and pencil;

- sanding machine (or sandpaper);

- jigsaw (or hacksaw);

- construction stapler;

- screws and screwdriver;

- brushes, stain and varnish;

- wood glue;

- wood putty;

- drill;

- construction square;

- clamps.

It is recommended to buy a little more lumber, since defective boards cut from low-grade wood are often found. Also, do not forget about knots, curvature and other defects that you may encounter. A jigsaw, sander and screwdriver are expensive tools, but you don’t have to buy them, you can just borrow them from your friends.

Assembling a double bed with your own hands

The preparatory activities are already behind us and it’s time to start the most interesting part - the manufacturing process. Particular attention should be paid to constant quality control and compliance with the dimensions noted in the drawing. Remember that there is no rush and the main thing is a quality result. We make a double bed in several stages:

- Main frame. A model equipped with a lifting mechanism additionally consists of a bottom and also starts with a frame. The parts are cut out with a jigsaw according to the dimensions indicated in the diagram, after which mounting holes are drilled into them to match the diameter of the screws. The ends of the boards are carefully sanded until completely smooth, after which they are opened with wood glue and fixed with self-tapping screws. Glue drips are carefully removed using a damp rag. Finally, you need to carefully check the corners with a square. After the structure has completely dried, it can be painted in any shade based on personal preference. In addition, for a frame that looks like a box, you will need to make a bottom (slatted or solid plywood).

Installation of supports from slats for the bottom. Holes for self-tapping screws are drilled in the support boards at intervals of 25 cm, and it is more convenient to install them if the frame is placed on its side.The first support is fixed at a distance of 5 cm from the bottom and, like the subsequent ones, it must be covered with wood glue. Fixation is carried out with self-tapping screws and then the support bar must be pressed with clamps. The mounting holes are covered with putty and, after it dries, sanded.

Installation of supports from slats for the bottom. Holes for self-tapping screws are drilled in the support boards at intervals of 25 cm, and it is more convenient to install them if the frame is placed on its side.The first support is fixed at a distance of 5 cm from the bottom and, like the subsequent ones, it must be covered with wood glue. Fixation is carried out with self-tapping screws and then the support bar must be pressed with clamps. The mounting holes are covered with putty and, after it dries, sanded.- Legs. The simplest stage is in which the beam is sawn into 6 elements 10.5 cm long and attached to the support bars. Four legs are attached in the corners and 2 more - under the central support, which makes the frame stronger. We use long self-tapping screws for this. Before screwing them in, it is also necessary to drill the mounting holes, which is especially important at this stage, since the likelihood of the boards splitting is high. Also, do not forget about carefully sanding each part until smooth.

- Decorative elements. They perform an important function - they give the finished product a finished look. A suitable option is wooden slats 5x2.5 cm. They are cut from prepared materials, sanded and covered with stain, the shade of which is also selected based on the concept of the room and personal preferences. When the slats are dry, they should be coated with varnish (preferably water-based), and in order to avoid the appearance of bubbles on the surface, the first layer is sanded, and then 2 more layers are applied. At this stage the bed legs are also varnished. The finished slats are glued to the frame, after which they are pressed for a short time with clamps. Glue smudges are carefully removed with a damp rag, after which the elements are fixed with self-tapping screws. The slats in beds equipped with a lifting mechanism are attached to the lifting frame.The principle of their manufacture is the same as that of decorative elements; they are cut to the required size and carefully cleaned with sandpaper.

- Headboard. An important detail that performs a decorative function, protects the walls, and increases the comfort of rest. Its size and shape are selected individually, as well as the finish. The best option would be to cut out the desired structure from sheet plywood, and then wrap it in fabric, after covering it with foam rubber.

To begin with, markings are applied to the plywood sheet, after which the part is cut out and its edges are sanded. Next, foam rubber is laid down, which is fixed with a construction stapler and upholstered with a fabric covering. The simplest option for finishing a headboard is to simply paint it or varnish it. The finished element is attached to the structure with several self-tapping screws.

The final stage will be to inspect the resulting bed and eliminate any shortcomings such as glue smudges or unevenness, if any. You should also re-measure the entire structure to ensure compliance with the dimensions indicated in the drawing.

Installation of the lifting mechanism

The popularity of the lifting mechanism is well deserved, since with its help a spacious and roomy laundry niche is created under the bed. The most common is a gas elevator, but when purchasing it, you should determine the maximum withstand load, which is indicated in the labeling. After purchasing the product you like, you can begin installing it:

- Mounting points are marked on the box and holes for the bolts are drilled.

- The lower part of the mechanism is fixed, and a corner is attached to the frame.

- The base is lowered and the places where the bar is fixed in its lowest position are marked on it.

- Holes are drilled in the frame according to the previously made marks, and the top bar is screwed to it.

NOTE. The installation of the lifting mechanism must be carried out strictly symmetrically, which guarantees its uniform operation and durability.

The process is quite labor-intensive and will require the help of one more person. Finally, the operation of the mechanism is tested and adjusted.

Soft covering

The cladding of the structure is done in the same style as the headboards. For this, thin foam rubber and a covering made of fabric, leatherette or any other are used. The bed elements are initially wrapped in foam rubber and fixed with a construction stapler, after which the excess material is carefully trimmed. Then fabric is applied to it, fixed on one side, after which it is slightly stretched and wrapped inside the structure so that the staples are not visible. In this case, the help of a partner will also not hurt, since it is very difficult to cover the bed yourself.

The cladding of the structure is done in the same style as the headboards. For this, thin foam rubber and a covering made of fabric, leatherette or any other are used. The bed elements are initially wrapped in foam rubber and fixed with a construction stapler, after which the excess material is carefully trimmed. Then fabric is applied to it, fixed on one side, after which it is slightly stretched and wrapped inside the structure so that the staples are not visible. In this case, the help of a partner will also not hurt, since it is very difficult to cover the bed yourself.

Original and functional additions

When making, instead of a lifting mechanism, you can install drawers that are assembled from boards or plywood. For this you will also need special roll-out sets of guides and rollers. The assembly process is very simple and consists of making drawers, the dimensions of which are selected in accordance with the parameters of the bed, and installing guides with rollers on them. For ease of use, the handles can be fixed at the front.

For spacious bedrooms, you can decorate the bed with a canopy.It is also not difficult to make - the entire structure consists of racks made of timber, coated with varnish or paint, connected to each other by crossbars on top.

Making a double bed with your own hands is a painstaking and difficult task, but the result will decorate your home, give you pleasure and ensure sound and healthy sleep. This is an excellent opportunity to realize the most daring design ideas and test your abilities in action.