DIY bunk bed

A bunk bed is the perfect space-saving invention. There are many design options. The beauty and functionality of the product depend on the skill and imagination of the craftsman. Furniture can be ordered or purchased at any store. But it’s much more pleasant to make a bed for children yourself. Today we will look at what types of such furniture there are, how to choose the necessary material and drawing.

A bunk bed is the perfect space-saving invention. There are many design options. The beauty and functionality of the product depend on the skill and imagination of the craftsman. Furniture can be ordered or purchased at any store. But it’s much more pleasant to make a bed for children yourself. Today we will look at what types of such furniture there are, how to choose the necessary material and drawing.

The content of the article

Types of bunk beds: photos

Let's look at the types of existing bunk sleeping structures and learn about their advantages:

- A bed with two beds located one above the other. This option can vary by the location of the stairs (from the facade or on the side), as well as the placement of sleeping places. The latter can be located parallel or perpendicular to each other.

- Product with a double bed on the lower level.

- Bunk bed with sofa on the lower level. The advantage of the design is a sofa that can fold out.

- Bunk bed with an extension ladder or roll-out drawers in the form of steps.

- Design with drawers and shelves. You can, if space allows, place a cabinet or an open shelf at the end.

- Although a loft bed is not considered a bunk bed because it has a single bed, some manufacturers include it in the list. In this case, the child’s desk, cabinets and closet are located on the lower level.

- Often in kindergartens they install “matryoshka” beds - the lower berth rolls out from under the upper one.

ATTENTION! For a design option with a sofa on the lower level, it is better to choose the transformation of the sofa - “Eurobook” or “Venice” (“dolphin”). The accordion or roll-out layout requires additional space in front of the bed (this space in the room must remain free).

Selecting material for making a bed

Before choosing a manufacturing scheme, you need to decide on the material from which the structure will be made. Beds can be:

- Wooden. Made from solid wood (pine, oak, beech, ash). They are characterized by increased strength and wear resistance, are environmentally friendly and do not cause harm to health. At home, it is better to choose wood to make a bed. Withstands high humidity and is not afraid of water.

- Metal. Made from various types of steel. Strength depends on the material chosen as the base. With a good paint coating, it will not be afraid of water and humidity.

- Chipboard. The most commonly used material in the production of furniture products. Environmental friendliness depends on the quality of chipboard. Lasts a relatively long time. Safety during use depends on the master (the side walls and bottom must be strengthened; it is better to take a laminate with a width of 22 mm and above). Economical option. Chipboard swells from water and the edges peel off over time.

- MDF. A relatively inexpensive option, it can be decorated with milling.Wide choice of colors. Usually MDF is used for the front part of the product. Although PVC film prevents liquid from entering, it is better not to experiment.

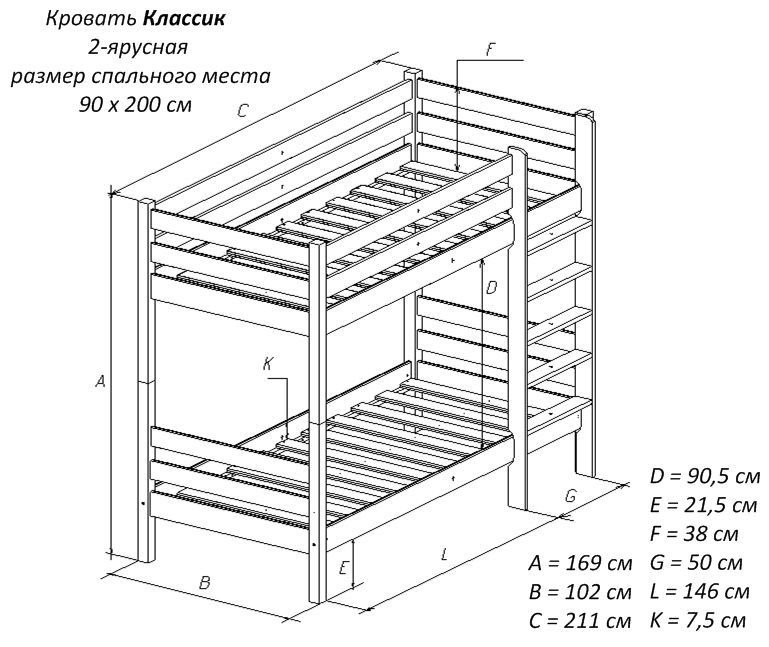

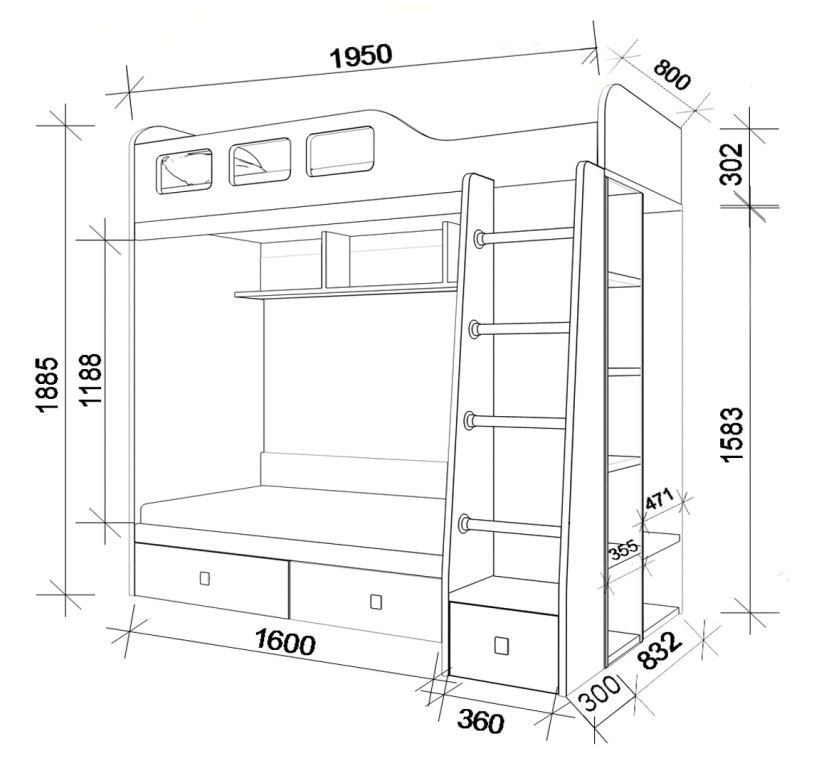

DIY bunk bed: drawings and diagrams with dimensions

After choosing the material, you need to choose or draw the bed diagram yourself.

ATTENTION! It must be remembered that when choosing a size, you must focus on existing mattress standards. If the mattress does not fit into the sleeping area, you will have to make it to order, which is fraught with additional costs.

So, first we choose the size of the mattress (it is better to purchase it before starting work), then we make a drawing. Leave a small allowance between the mattress and the material for ease of making the bed.

It is better to make a general drawing in two versions:

- familiar to us from school times from 3 projections;

- three-dimensional drawing or general diagram.

It is necessary to make assembly diagrams for various parts.

IMPORTANT! When creating a drawing, you need to remember the width of the material. Dimensions are the extreme points of the outer case. If the drawing of a laminated chipboard product indicates 205 mm, then 5 mm goes to the thickness of two laminate sheets. Drawers count against guides.

Bed with two tiers made of solid wood

Let's look at an example of manufacturing a wooden two-tier structure. After the drawing, you need to prepare the tools:

- drill (it’s better to take an electric one);

- plane (for cleaning the surface and adjusting to the size of the planks);

- level (for even placement of horizontal slats);

- roulette;

- self-tapping screws (nails quickly become loose);

- screwdriver;

- a simple pencil;

- jigsaw;

- hacksaw.

Assembly steps:

- The boxes for the lower and upper tiers are assembled in the same way: 4 strips are connected using bars and screws. We attach a bar to the two long sides on which the lamellas will be attached. It is necessary to calculate the distance between them: it should not be very large, otherwise the mattress will be deformed.

- Next, you need to assemble the sides of the frame. We make the main supports from timber onto which the remaining parts will be attached.

- The fastening points can be decorated with treated bars or plastic plugs.

- We attach the lower and then the upper tier of the bed to the frame. Only after this the lamellas are attached to the box.

- The ladder is assembled separately and attached to the bed.

- The last stage of assembly will be the distribution of drawers, shelves and other additional elements.

- For beauty, the bed can be covered with stain or furniture varnish.

IMPORTANT! The four main supports must be flawless and quite strong, safety depends on this. Let the product look less aesthetically pleasing.

Metal bunk bed

The steps for assembling a metal bed are identical to a wooden one. You just need to fasten the parts with corners using a welding machine. For sun loungers, you can choose metal mesh or iron slats.

Of course, you can take an easier route: first weld the side parts, then put 4 longitudinal pipes on their corners for the base of the tiers, then weld the transverse slats and put the mesh.

This bed is decorated with thin round slats. The ladder is attached. Upon completion of assembly, the structure is covered with two layers of paint.