DIY chair bed

Owners of small apartments often have problems with purchasing furniture and where to place it. Due to the small size of the premises, sometimes it is not even possible to install a regular bed. To save useful space without sacrificing comfort, you can make a chair-bed yourself.

Owners of small apartments often have problems with purchasing furniture and where to place it. Due to the small size of the premises, sometimes it is not even possible to install a regular bed. To save useful space without sacrificing comfort, you can make a chair-bed yourself.

The content of the article

How to make a chair bed yourself

Chair-beds are small in size and at the same time solve several problems at the same time. During the day, this furniture is used as armchairs, and when night comes, it transforms into a comfortable place to sleep.

Before you start making a chair-bed, you need to determine which model is best suited to the design of a particular room. To do this, several questions need to be addressed:

- What size should a chair bed be?

- What type of cladding is practical in each specific room?

- In which specific room will the furniture be located?

Naturally, the main aspect is the purpose of the furniture. At night, the product turns into a full-fledged bed, that is, when choosing a specific model, you need to focus on obtaining maximum comfort while resting.

When choosing upholstery, try to choose a material that can withstand cleaning well (especially if you have pets).In addition, when purchasing textiles, be sure to find out whether the fabric is impregnated with special substances to prevent stains.

Natural fabrics do not interfere with normal air exchange, but artificial materials increase the practicality of furniture and simplify its care.

Attention! The dimensions of the chair-bed are selected on a case-by-case basis. If furniture is needed for a small room, then you must definitely take into account the dimensions of all installed furniture and the dimensions of the unfolded chair-bed.

Selection of materials

To make furniture you will need the following material:

- Fibreboard is used to create longitudinal parts of any size that can be manufactured. Most often, a sheet of medium thickness but high density is selected. You can also choose a laminated board (HDF), which will additionally make it possible to avoid toxic fumes. Disadvantages include fragility and a small choice of design, while in terms of budget the cost of this material comes first.

- Furniture board is used like fiberboard, but has better strength properties and a more attractive appearance. The disadvantage is the high cost, because of this it is installed only in open areas.

- Edged board - the density will depend on the type of wood. The board is quite difficult to process due to its physical characteristics. As a rule, it is used as an additional material, but in some cases (if the loads are insignificant) it is a replacement for HDF.

- Beam - used as support and support for the structure. As a rule, its presence is practically invisible, but without it no structure will be strong.

- Foam rubber and synthetic winterizer are fillers for upholstery products.

- Spunbond is placed on top of the filler, due to which it is firmly fixed. This material is also convenient when tensioning the outer skin, as it can provide good sliding.

Required Tools

Before you start making your own chair-bed, you must first prepare the tools that you will need for the job. For production you need:

- Furniture fittings.

- Electric jigsaw.

- Screwdriver.

- Sander.

- Milling machine.

- Roulette.

- Square.

- Marker.

- Sewing machine.

- Scissors.

- Furniture stapler.

- Seam fittings.

- Upholstery materials.

- Chalk.

How to take measurements correctly

Before you start making a chair-bed, you need to determine the place where you need to install the furniture and make measurements and diagrams of the room, taking into account the size of the sofa when unfolded.

When choosing the size of furniture, you need to take into account the size of the room. A bulky chair-bed in a small room with low ceilings looks unsightly, the same applies to small-sized chairs in a spacious room - the furniture will be “lost” against the background of the entire interior.

Attention! When choosing the size, you also need to take into account the height of the person who will sleep on the chair-bed.

DIY chair-bed: step-by-step instructions

Operating conditions and the dimensions of the room dictate a certain installation of the mechanism for folding out the sofa. There are several ways:

- retractable mechanism;

- Eurobook;

- click-clack;

- dolphin.

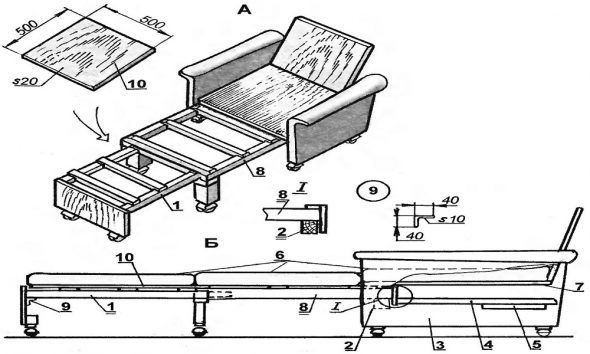

The retractable system is the optimal solution for novice furniture makers. It is the most reliable in operation. To transform the chair into a bed, you need to pull two parts forward and lower the backrest into the free space.Bolts and piano hinges are used to fasten the elements. Using this mechanism you can also get a box located at the bottom of the box.

The disadvantages include the fact that when assembled, a chair with a retractable system looks bulky, but the strength and presence of a linen drawer compensate for this disadvantage.

Next, taking into account the drawing, all elements of the sleeping part and the body of the chair are cut out. You need to cut four squares from a plywood sheet. The folding part will require 3 pieces, and 1 is used for the backrest. Sawing is done with a wood hacksaw or an electric jigsaw.

Timber cutting:

- 4 things. for legs;

- 7 pcs. for crossbars;

- 6 pcs. for the longitudinal part of the bed.

Mark the connection points of all elements and make holes using an electric drill. Armrests are cut out of fiberboard and bolted to the main structure. All parts are fastened with furniture screws into pre-drilled holes. Batting is glued to the sides, back, and all elements of the berth.

Next, the furniture is upholstered. There are many cladding options. As a rule, flock, velor, jacquard or chenille are chosen.

The material is cut taking into account the thickness of the filler and the dimensions of all structural elements. Each part is covered with a blank made of the selected material and fixed with a furniture stapler. The case is ready, to operate the product you need to connect all the parts.

You can also make frameless chair-beds. These models are most often chosen by young people. The furniture is reliable and follows fashion trends. The frameless product has no rigid elements; it is a transformer made of pillows.

Having made several of these chairs, it becomes possible to combine them.You can make a sofa and move it around the room, placing it near the TV. No carpentry work is required; for production you need scissors, a sewing machine, chalk, and a tape measure.

The chair-bed is made of foam rubber, which has a thickness of at least 12 cm. The sheets are glued in pairs with PVA glue. Afterwards, the sheets are cut out using a tape measure and chalk, cut out clearly according to the markings with scissors, and the blanks are obtained:

- rectangle 30x90 cm – 2 pieces;

- rectangle 40x90 cm – 1 piece;

- square 90x90 cm – 2 pieces.

The cut out elements have a thickness of 24 cm. The next stage is cutting the material. When doing the work, the main thing is not to forget about the seam allowances; they are made at least 3 cm, in places where the zipper is sewn in - an allowance of at least 4 cm.

Sew two types of covers:

- Rough ones made of cheap material.

- Elegant from high-quality textiles.

Attention! It turns out several blanks that are stacked on top of each other; they are equal to the size of the cut foam rubber. All elements are assembled into the overall structure using zippers sewn to the covers.

By making your own chair-bed, you can get functional and practical furniture that meets all the necessary requirements and at the same time with low material costs. Using all the recommendations in practice, you will have a comfortable place to relax.