DIY wooden chair

The design of a garden area or the interior of a living space will be perfectly complemented by a wooden chair. Any craftsman can assemble this structure on his own; you just need to be patient, stock up on the required tools and necessary materials, and also draw up a suitable drawing.

The design of a garden area or the interior of a living space will be perfectly complemented by a wooden chair. Any craftsman can assemble this structure on his own; you just need to be patient, stock up on the required tools and necessary materials, and also draw up a suitable drawing.

The content of the article

How to make a chair out of wood with your own hands

In order for the furniture to last for a long time, the product must meet certain requirements:

- Protection from negative environmental influences. Prolonged exposure of furniture to rain or direct sunlight can significantly deteriorate the original appearance of the product. Preparatory work for protection begins at the first stages of manufacturing. Well-dried wood is the key to success. If the material is initially of poor quality, dry the wood. Sand, treat the workpiece with antiseptic and drying oil. At the last stage, after drying the assembled chair, it needs to be varnished.

- Choice of material. One of the main requirements when assembling furniture yourself is the use of hardwood. Despite the high cost, the result after assembly due to high-quality raw materials will be excellent.

- Mobility. Most often, wooden chairs are made for installation on a personal plot.If the weather changes unexpectedly, the furniture can be moved under the canopy.

Tools and materials

To make a wooden chair yourself, you need a set of tools:

- electric drill;

- wood saw;

- plane;

- miter box;

- brush;

- screwdriver;

- pliers.

Attention! Also during the work process you will need paints, stain, dowels, primer, bushings, screws and other materials - taking into account what kind of chair needs to be made and what you plan to choose as the material (MDF, fiberboard, plywood).

Design selection

Taking into account individual preferences, you can make:

- Folding products are great for those who love country trips. They can be installed in open gazebos. This furniture is very compact, which is important for owners of small extensions.

- Shell chair. For manufacturing, it is advisable to choose oak or walnut. This wood can easily withstand mechanical loads, and the texture of the wood makes it possible to save on finishing.

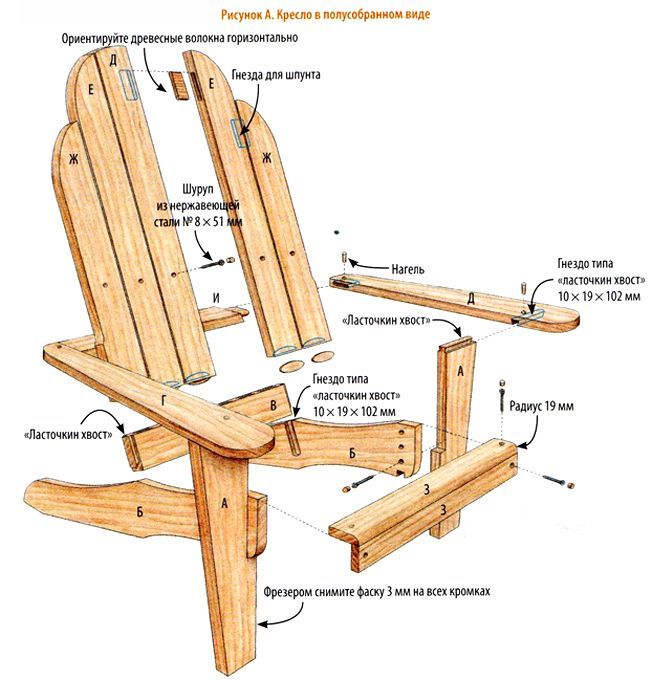

- Adirondack in the form of a throne or sliding models for relaxing on a personal plot.

How to take measurements and drawings correctly

Before you start assembling the chair yourself, you need to draw up a drawing, deciding which specific product is required.

The manufacturing stages will depend on which design is taken as a basis, but assembly occurs according to a single algorithm:

- Seats, backrests, armrests, guides, and legs are cut out of wood.

- All elements are processed with a milling cutter, sanded, and treated with an antiseptic.

- To fix all parts, self-tapping screws are used, which are screwed into pre-made holes.

- The assembled structure is treated with colorless varnish or acrylic paint.

Do-it-yourself wooden chair: step-by-step instructions

To make the back, legs and armrests you will need wide beams of the same texture, which need to be glued together.

To make the backrest, it is necessary to cut the prepared blank from glued beams. The bottom of the backrest must be cut at 11 degrees so that the backrest fits securely to the rear legs. The top edge needs to be rounded. Then the structure is assembled, all elements are precisely adjusted to each other.

The legs are attached with self-tapping screws and wood glue. Corner fasteners are used to connect side elements and legs to each other. To close the gaps that appear, you can use strips that are secured with screws. The stronger the connections are made, the more reliable the finished product will be.

Attention! The seat of the chair is attached to the back using a groove. The fasteners must be made at an angle, this way you can create a good joint tightness. When cutting off the workpiece for the front legs, you need to bevel these parts at an angle of 7 degrees from above. Then you need to secure them to the frame using glue and self-tapping screws.

A homemade wooden chair is not very durable, so professionals advise additionally strengthening the structure in the form of installing legs. To do this, you need to measure their location and, taking this into account, cut off the corresponding element from the bar. Wedge-shaped supports attached to the front legs will help you assemble a more convenient design.

At the last stage, when all the elements are already connected, final sanding can be done. After this, the surface of the garden furniture must be perfectly smooth.Then the furniture can be painted in the desired color or treated with several layers of transparent varnish, which can help preserve the natural structure of the wood.

A wooden chair is the simplest furniture to make. You can independently make a comfortable, original and stylish product for your garden plot, cottage or home. Often this solution is much more economical, in contrast to purchasing ready-made furniture.

In addition, with the help of wood you can make yourself not only an armchair, but also other furniture, for example, a sofa, a wardrobe, a chair. There are various photos on the Internet that show the manufacturing process in detail. This furniture can not only decorate any interior, but also give it a special charm.