Furniture foam rubber - what density is needed for a sofa?

Over time, as a result of use, upholstered furniture loses some of its characteristics and becomes not as comfortable as initially. Pits or bumps form on the sofa. It is no longer possible to have a good rest on such a sofa. This can happen due to the use of low-quality filler or due to improper use of upholstered furniture. If you wish, you can restore the furniture yourself; just buy new foam rubber and replace it in the sofa. You need to study furniture foam rubber to understand which one to choose for the sofa.

Over time, as a result of use, upholstered furniture loses some of its characteristics and becomes not as comfortable as initially. Pits or bumps form on the sofa. It is no longer possible to have a good rest on such a sofa. This can happen due to the use of low-quality filler or due to improper use of upholstered furniture. If you wish, you can restore the furniture yourself; just buy new foam rubber and replace it in the sofa. You need to study furniture foam rubber to understand which one to choose for the sofa.

The content of the article

Types of furniture foam rubber

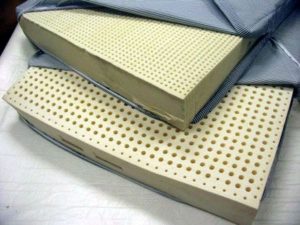

When choosing upholstered furniture for your home, it is very important to pay attention to its comfort. It would be a good idea to ask which filler the manufacturer chose for the manufacture of a particular model. A wide variety of brands can confuse an inexperienced specialist, let alone an ordinary buyer. The selection criteria are density and thickness.

REFERENCE. To assemble upholstered furniture, it is necessary to use material with a density of 30 kg per cubic meter. m. Such sofas can be used both for sleeping and for relaxing while sitting. During operation, the filler is not pressed through.

IMPORTANT. The duration of use of the furniture will depend on the density of the foam rubber. The dependence works - the higher the density, the longer the period of operation.

For the manufacture of furniture seats and armrests, a material with different characteristics is used, this is explained by different degrees of load.

Thickness is an equally important indicator. If we are talking about a sofa for sleeping, the thickness should be at least 4 cm. Furniture manufacturers often neglect this criterion and use thin foam rubber, which significantly reduces the quality of the furniture.

Quality indicators

When choosing foam rubber, you must first of all pay attention to its main parameters: thickness and density. The quality and scope of application of this material are influenced by the following qualities:

Filler density. The higher this indicator, the longer the material will last.

Filler density. The higher this indicator, the longer the material will last.- Compressive stress. The standard kPa value should be 40% in the compressed state.

- Fortress. This indicator is determined by rupture and elongation during the rupture process.

- Elasticity. This indicator is determined based on the rebound height at the time of testing.

- Residual deformation. After the load is removed, the surface should return to its original shape as quickly as possible. The dependence works here - the higher the density of the material, the less susceptible it is to deformation.

REFERENCE. Manufacturers indicate letters in the name of foam rubber that allow you to quickly determine its class. The numbers indicated in the name will help determine the density and compression stress.

Purpose of brands of furniture foam rubber

There is a certain classification of foam rubber, on its basis you can determine what material is intended for what purposes. First of all, you should understand the brand designation. Manufacturers use Latin letters:

ST is the most common material, standard type.

ST is the most common material, standard type.- HL and EL - this material already belongs to the rigid type, the second option is of increased rigidity.

- HS is a soft or ultra-soft material. Quite often used in sofas.

- HR is a designation for highly elastic material.

- LR - this material will be soft and viscous in structure.

- RTC is a reticulated polyurethane foam with increased porosity.

Designation in Latin letters is only part of the encrypted characteristics. There are also numbers. The initial numbers indicate the density of the foam, and the other two indicate the compressive stress.

Just based on the markings, you can understand which material is suitable for what purposes.

What kind of foam is used in sofas?

To complete sofas, manufacturers use several types of foam rubber, depending on what characteristics the furniture should have. Let's look at the question - furniture foam rubber - what density is needed for a sofa?

For upholstered furniture, an excellent choice would be 30–40 kg per cubic meter. m. If we are talking about children's upholstered furniture, it is better to give preference to material with an indicator of 25 kg per cubic meter. m. Foam rubber 1620 is one of the softest, but its durability leaves much to be desired. It is suitable for the manufacture of furniture or its elements that are not subject to high loads.

Material grades 2336 and 2310 are most often used by manufacturers in the manufacture of teenage furniture; they are considered durable. They are also very often chosen as a layer for springs.

REFERENCE. The most commonly used grade in furniture production is 2536.

Modern production offers a very wide selection of filler brands, which makes it possible not only for furniture manufacturers, but also for ordinary buyers to select the necessary items of goods.