DIY plywood sofa

To save money and enjoy the process, you can design your own furniture. It will not take much time, and it will not require a lot of effort and special skills and knowledge. On the contrary, you can make a structure that will delight you and take into account personal preferences.

However, before starting manipulations, you need to identify the main points that contribute to a productive process.

The content of the article

Choosing a pattern for creating a sofa

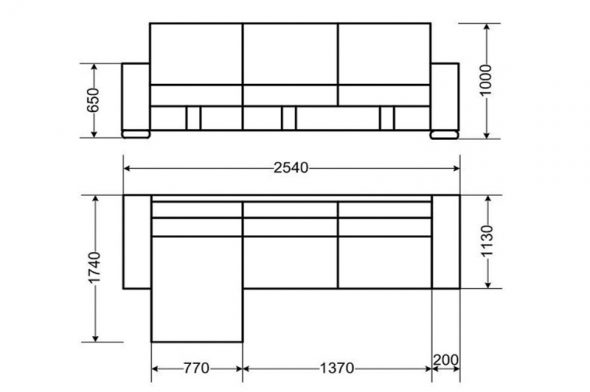

First you need to decide what model of plywood sofa you will create with your own hands. Below are options for the different devices that may exist. Since the samples have been tested by many masters, you can safely use the indicated parameters.

It is worth remembering that if you are going to change them to suit your desires, then by changing one indicator, you need to do the same in proportion to the others.

Preparation of plywood and other materials and tools

For a structure without sharp edges, a product will be required so that it can withstand a certain load. Furniture panels or thick plywood are perfect for this. As for the shaped parts, it is better to choose fiberboard, which in the future must be specially reinforced with boards.

For a structure without sharp edges, a product will be required so that it can withstand a certain load. Furniture panels or thick plywood are perfect for this. As for the shaped parts, it is better to choose fiberboard, which in the future must be specially reinforced with boards.

To make a model with an angular shape, it is worth purchasing wooden slabs, plywood, planks, padding polyester and fabric. You also need bars and a fiberboard sheet. As for the tools, these are:

- Self-tapping screws and nails.

- Angle plates.

- Stapler.

- Drill.

- Loops.

How to assemble a rounded sofa, corner structure, sofa book

After the preparation is completely completed, you can proceed to the main part.

After the preparation is completely completed, you can proceed to the main part.

- The frame of the rounded sofa is made up of a panel of three layers, and the back is also made. After which you need to cover it with foam rubber, and not from one type, but from four. They should vary both in softness and density, and in thickness. You need to stick cotton wool on them, namely, 100 grams for each square meter. You should not forget about the cover, which will need to cover the entire structure. For complete comfort, equip the product with pillows and legs;

- For a corner structure, the first step is to create a seat, for which you will need to fasten the boards (their width = 20 cm). A slab is used as the bottom. Next, you can proceed to the frame: the main part is sheet material, the back is fabric. The same manipulations must be performed for the upper seat. The entire structure must be covered with foam rubber and synthetic padding. The base is ready. Now the corner part: it can be made from sheet products, and then also covered with batting. The final step is making the supports and equipping the product with a cover. First you need to make holes for them;

- Using the beams, you should make a box, connecting them as shown in the diagram. It is worth attaching fiberboard to the product. Next, you need to create rectangular parts from bars, which are then connected. Slats are attached to them.You need to cut out the side walls from a sheet of chipboard, cutting out holes for them in advance. After this you need to collect all the elements. To do this, it is worth purchasing separate mechanisms sold in stores. They need to be secured between the back and the seat. Next, follow the standard procedure: cover everything with foam rubber and put on a cover.