DIY wooden sofa

Buying from a store is not the only way to get a sofa. You can create a new piece of furniture from wood, foam rubber and textiles with your own hands. And then it will turn out to be original, exactly corresponding to specific desires and requests, and significantly cheaper.

Buying from a store is not the only way to get a sofa. You can create a new piece of furniture from wood, foam rubber and textiles with your own hands. And then it will turn out to be original, exactly corresponding to specific desires and requests, and significantly cheaper.

The content of the article

Materials for making, DIY sofa options

To make a sofa you can use:

- boards;

- particle boards;

- plywood;

- beam;

- wooden pallets;

- or several of the listed options together.

A variety of models are made from different materials. The simplest, minimalist products can be constructed from fragments cut from plywood, or from thick boards, as well as pallets. But complex furniture of unusual shape is always a combination of several materials. For example, for a book sofa you will need timber, boards and chipboard.

IMPORTANT! Don't skimp on materials! High-quality types of wood combined with good fabric will allow you to create a stylish craft item. And even a simple product made from boxes will give the impression of a fashionable acquisition in the loft style, upholstered in leather, suede or expensive textiles.

How to make a sofa book with your own hands

This practical folding model can be made by following the instructions.

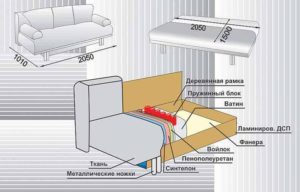

Frame making

For this you will need:

- timber with a section of 50x50 mm;

- boards 25x200 mm;

- thin wooden slats;

- chipboard sheets 2.5 mm thick;

- foam rubber sheets with a thickness of at least 60 mm;

- textile.

First you need to completely assemble all the frame elements. The boxes are a rectangle of boards placed on their sides and fastened together with nails or screws. For greater rigidity and stability of the structure, additional timber is installed between the boards in increments of 500–600 mm.

The seat and backrest are two identical rectangular panels made of timber, corresponding to the size and configuration of the box. Slats are attached on top of the timber frame at intervals of 50–100 mm. It is on them that the mattress will be attached.

The armrests are cut from chipboard. The configuration may vary, but the total width of these elements should be slightly larger than the size of the drawers. On the inside, the armrests are additionally reinforced along the contour with timber.

Assembly

Now the resulting elements need to be assembled together. You will need nails, screws, and a special folding mechanism sold in the hardware department.

IMPORTANT! When open, the seat and back panels must have a gap of 10–15 mm between them.

First, assemble the seat and backrest using the folding mechanism. Then connect them to the bottom of the structure. Armrests are added only after the last stage of work - upholstery.

Upholstery

In this process, it will be the turn to use foam rubber, glue, and textile covers. First of all, the foam rubber is glued to the back and seat. Usually, to do this, a thin layer of non-woven or chipboard is first attached to them.The armrests on the inside are processed in the same way. A thicker layer of soft material is made in the upper part of the armrests and on the outer edge of the seat. Then all the elements of the sofa are connected together and put on a textile cover. A beautiful and comfortable piece of furniture is ready!

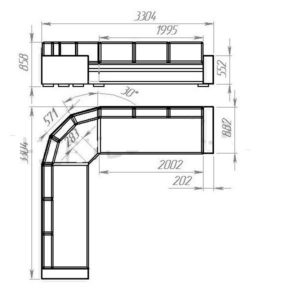

DIY corner sofa made of wood

This type of upholstered furniture does not allow for folding, so its design allows you to experiment.

IMPORTANT! Before starting work, it is worth drawing a sketch of the future product. Outline the frame, overall dimensions, height, width, shape.

The procedure for assembling a corner sofa has some features:

- Manufacturing the lower part of the structure. That is, the seat and frame, which ensures the stability and strength of the thing. At this stage, boards and timber can be used

any section; pallets; sheets of plywood. The plane to which the seat upholstery is attached is made of chipboard or plywood.

any section; pallets; sheets of plywood. The plane to which the seat upholstery is attached is made of chipboard or plywood. - Backrest installation. It can be located at a right angle to the seat or have a slight slope so that it is convenient to recline on it. The material for this part of the work is usually timber, boards, plywood or chipboard.

- Armrests. This model may not have them. But if you do make them, you should follow the same principle as when creating the side parts of a sofa book.

IMPORTANT! Finished wooden elements should be impregnated with stain or varnished - then they will turn out more beautiful and durable.

The upholstery stage using foam rubber, padding polyester, textiles and glue is carried out according to the standard scheme already described above.

Making your own unusual sofa

One of the main advantages of making furniture yourself is the ability to invent models of any configuration and style on the fly. Below are some interesting ideas:

- Sofa with shelves. This can be implemented in different ways. One of the options applicable for sofas made from thick plywood sheets is to extend the plane of the seat instead of installing an armrest on one or both sides. Thus, it turns out that on the side of the mattress there is a wooden shelf that can be used as a stand for a pot of flowers. Or as a coffee table. Another option is to make a narrow long shelf as an extension of the back of the sofa. Artificially increase its thickness due to additional reinforcement of the frame.

- Backlight. By stretching an LED strip behind or under a piece of furniture, you can visually make it lighter and more interesting. In the dark, such products look very impressive.

- Sofa with drawers. In the lower part, between the frame elements, you can install drawers. In this way, the space in the room will be used more efficiently. It looks quite unusual.

Perhaps your imagination will tell you dozens more options!

DIY rounded sofa

Curvilinear sofas are also not particularly difficult to manufacture. First you should:

- Cut out the seat panel. The seat panel should be cut from such shields. It will be convenient to do this using a pre-prepared template. The design will be more stable if you duplicate the same panel for the lower part of the sofa frame.

- Make a frame. Now the curved panels need to be strengthened using the same timber and boards. A large number of cross elements with small spacing are a good solution.

IMPORTANT! For rounded furniture, the main thing is to choose the right material. It can be good thick plywood or high-quality furniture panels.

Other stages of work - creating the backrest, armrests, upholstery - are performed according to the same algorithm as in the previous cases under consideration. A DIY sofa is an excellent solution for those who want to make their home more elegant and comfortable.