What is polyurethane foam filler in a sofa?

After the renovation is completed, people often purchase furniture. The choice of a specific model in the future should provide comfort to the owners. In addition to strength characteristics and design, the filling of the sofa plays an important role. The modern market presents many models, so first of all you need to decide on the purpose of purchasing the product. If a sofa is purchased for sleeping, then a harder filler is chosen; for other cases, simpler options are considered.

After the renovation is completed, people often purchase furniture. The choice of a specific model in the future should provide comfort to the owners. In addition to strength characteristics and design, the filling of the sofa plays an important role. The modern market presents many models, so first of all you need to decide on the purpose of purchasing the product. If a sofa is purchased for sleeping, then a harder filler is chosen; for other cases, simpler options are considered.

The content of the article

What is polyurethane foam filler on a sofa?

PPU material is superior to rubber and caoutchouc in its characteristics. High density allows you to obtain high-quality products from polyurethane foam. For furniture, polyurethane foam with an index of at least 30 km/m3 is used. Materials with a lower value are used only for making pillows.

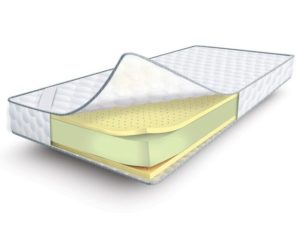

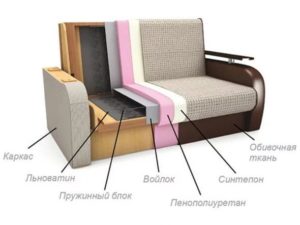

This “filling” is characterized by the absence of wire blocks. The entire space inside is occupied by polyurethane foam (abbreviated as PPU). The material is a subtype of foam rubber. When making some models, contour cutting is used, which provides an attractive design along with comfort.

Polyurethane foam is produced by artificial gas filling of polyurethanes.

Advantages of PPU filler:

- the composition does not include allergens, which later become a breeding ground for microorganisms;

- the material is made from environmentally friendly substances;

- allows air to pass through;

- quickly restores shape after deformation;

- availability;

- used in various furniture products.

Disadvantages of PU foam filler: - poor resistance to sunlight;

- flammable;

- highly elastic;

- does not withstand heavy loads.

Furniture with polyurethane foam filling is practical and durable.

Important! Often problems with the spine and restless sleep are associated with the place where a person sleeps. That is why it is important to choose the right furniture.

Varieties of ppu

Depending on the source raw material, polyurethane foam has the following classification:

- Hard. Used for thermal insulation, sound insulation, and construction.

- Elastic. Household filters, sponges, and gaskets are made from it.

- Self-foaming. Included in polyurethane foam and adhesive joints. With the help of such materials, voids are filled and insulation is carried out.

Based on the type of sofa filling, PU foam is divided into two types:

- Blocky. This form is produced by the supplier in the form of a large block. At furniture factories it is cut into layers of the required size. The result is a part of the sofa made from sheets of different densities.

Molded polyurethane foam. Produced by pouring hot liquid into prepared molds. - During a chemical reaction, the filler takes on a given shape under pressure. The result is blocks of the specified sizes. The advantage of such production is the absence of waste after processing.

Sheet polyurethane foam. It consists of thin sheets that cover the blocks during the production process and provide softness to the seat. Used to treat sofas before upholstery. - PPU crumb. During the production of blocks and sheets, crumbs are waste. This type is used for stuffing decorative pillows.

Attention! The cast type is more expensive due to the long production process.

There are a number of soft paddings that are used together with others to give furniture softness or hardness, as well as improve other characteristics. They can often be found filling armrests and backrests, as well as filling decorative pillows.

Types of soft fillers:

- Sintepon. The structure contains straight fibers and is very light.

- Holofiber. As a result of treatment with silicone, elastic balls are obtained, which have the advantage of quickly regaining their shape.

- Synthetic fluff. Widely used to replace natural down. Lightweight and voluminous material, resistant to deformation.

How to choose a pillow on the sofa

Not all materials are of good quality. The entire complex of necessary properties is contained only in polyurethane foams that have gone through all stages of processing.

Before purchasing a sofa, you should inquire about the density of the filler; the optimal value is 30 kg/m3 for the seat, and 25 kg/m3 for the backrest. The higher the density, the better the quality and service life.

Another important characteristic is the thickness of the polyurethane foam. The minimum value is 4 cm. Some manufacturers, in order to save money, use a thickness of about 3 cm. It is advisable to avoid such furniture, especially if it is purchased for active use and sleep.

The most suitable fillings for pillows:

- holofiber;

- padding polyester;

- synthetic fluff.

Due to their advantages, the pillows will have special comfortable and soft characteristics.

Sofas for sleeping are optimal with hard and dense fillings. In this case, the most suitable orthopedic conditions are observed.

Important! Sofas for living rooms are chosen from high-density polyurethane foam.Suitable additional filling: holofiber or synthetic down.

Very often, when choosing furniture, a person gives preference only to the appearance, cost and quality of the top layer. During operation, these parameters fade into the background, because the main thing is comfort for the human body and long-term use. When purchasing a sofa, you should test it yourself to ensure the density of the filling. You should be careful when purchasing, because a person will spend a lot of time on the sofa.